High-gloss color-changing lipstick and preparation method thereof

A high-gloss, lipstick technology, applied in the field of high-gloss discoloration lipstick and preparation, can solve the problems of low gloss, not full color, poor stability, etc., to achieve a pleasant experience, maintain color stability, improve gloss and color saturation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In a second aspect, an embodiment of the present invention provides a method for preparing a high-gloss color-changing lipstick, wherein the high-gloss color-changing lipstick is any of the above-mentioned high-gloss color-changing lipsticks, comprising the following steps:

[0046] Stir the A1 phase evenly, the A1 phase is the first liquid oil, and the liquid oil includes the first liquid oil and the second liquid oil; then add the A2 phase and the A3 phase, and the A2 phase is a solid wax, The A3 phase is bis-behenyl alcohol / isostearyl alcohol / phytosterol dimer linoleyl dimer linoleate, diisostearyl malate and phenyl silicone oil; heated to 85°C-90°C ℃, melted and mixed to obtain phase A mixture, cooled for later use;

[0047] Grinding the B1 phase until the material body is uniform, the B1 phase is the color paste obtained by mixing and grinding the second liquid oil, bromic acid red pigment and stearic acid;

[0048] After mixing and grinding the B2 phase and the B...

specific Embodiment

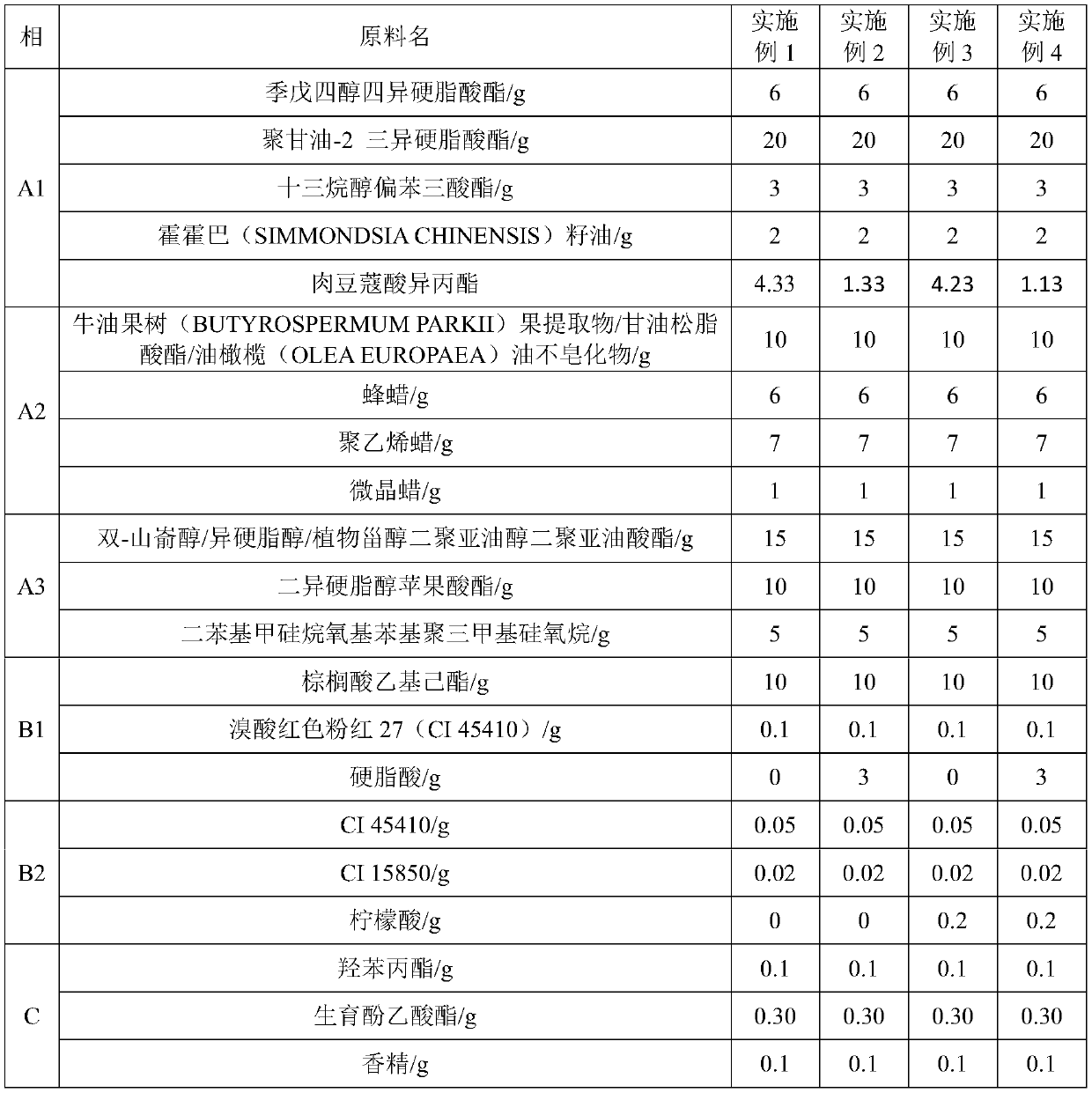

[0054] The component content of embodiment 1-4 is as shown in table 1:

[0055] Table 1

[0056]

[0057] Stability test results (open exposure test for three months, compared with the standard color number lipstick sample color appearance, the degree of discoloration is scored from 0-3, 0 points do not change color, 3 points obviously change color) The results are shown in Table 2:

[0058] temperature 25℃ 5℃ -18℃ 40℃ 48℃ Example 1 2 2 3 3 3 Example 2 2 2 2 3 2 Example 3 1 1 2 2 1 Example 4 0 0 1 0 1

[0059] The results of the stability test in Experimental Example 1 show that the double pH control of stearic acid and citric acid can effectively prevent the color change stability of the lipstick.

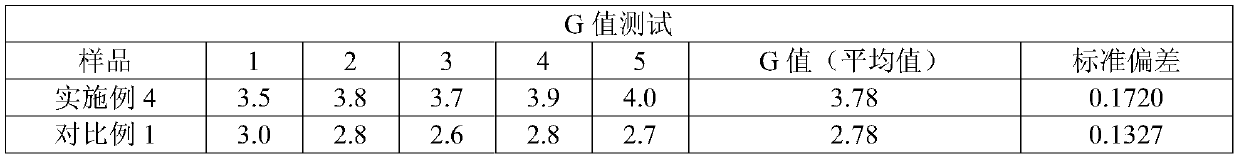

[0060] Determination of lipstick gloss using BYK gloss tester

[0061]Experimental principle: The built-in light source of BYK gloss tester is used to irradiate the surface of the sample at an incident angle of 60°, an...

experiment example 2

[0071] Experimental example 2 shows that by adding the specific oil combination of the present invention, the glossiness of the color-changing lipstick is significantly improved compared with comparative example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com