Pollutant solid remover spraying device for branch tube

A spraying device and removal agent technology, which is applied in liquid spraying device, spraying device, gas treatment, etc., can solve the problems that pollutants easily enter the external air, the diffusion effect of the direct nozzle is not very good, and the diffusion area is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

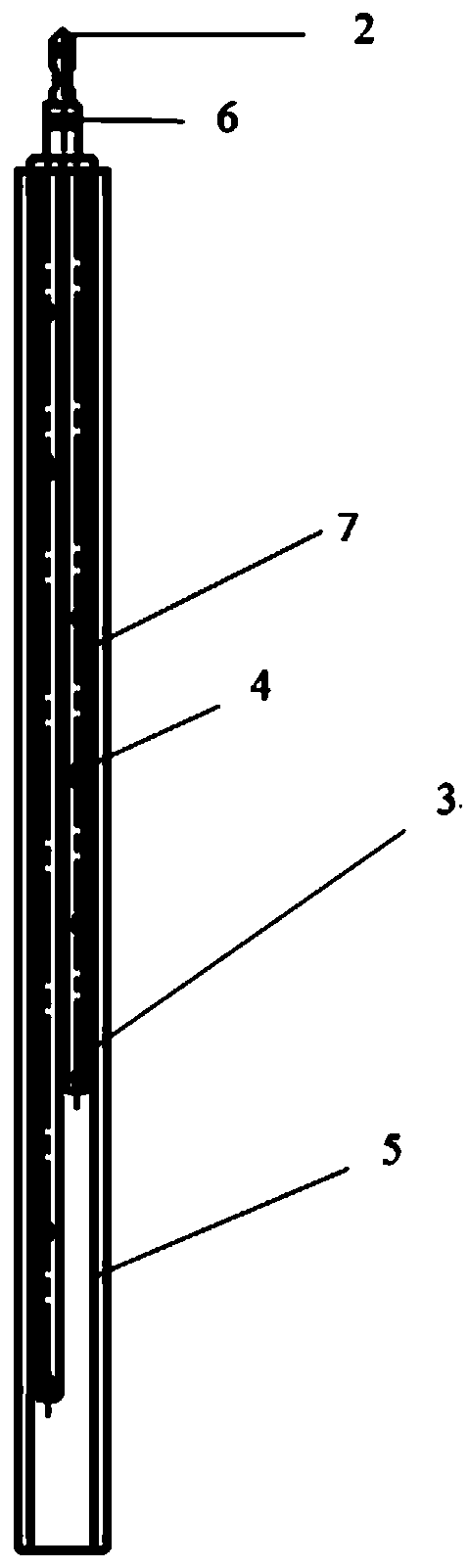

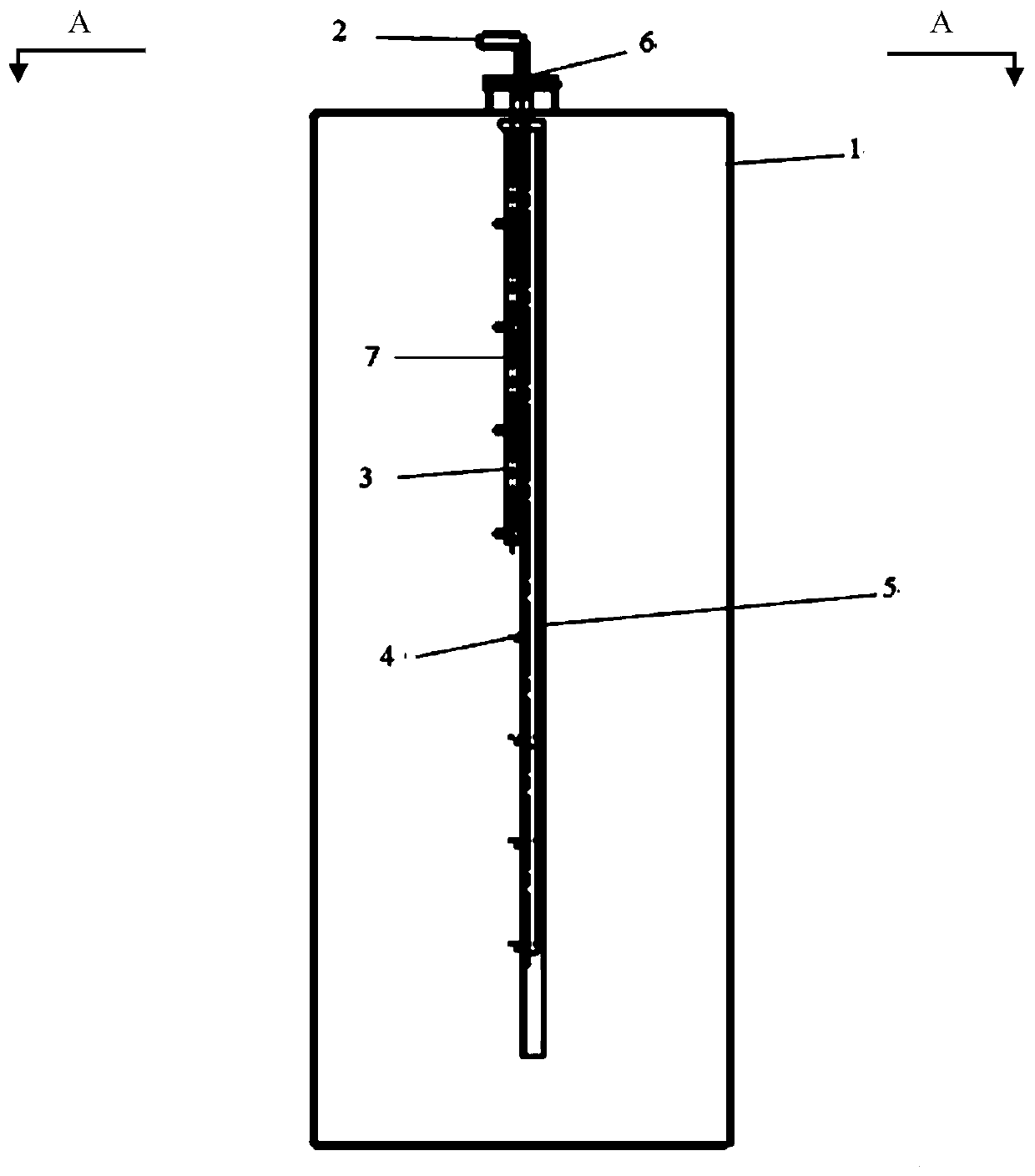

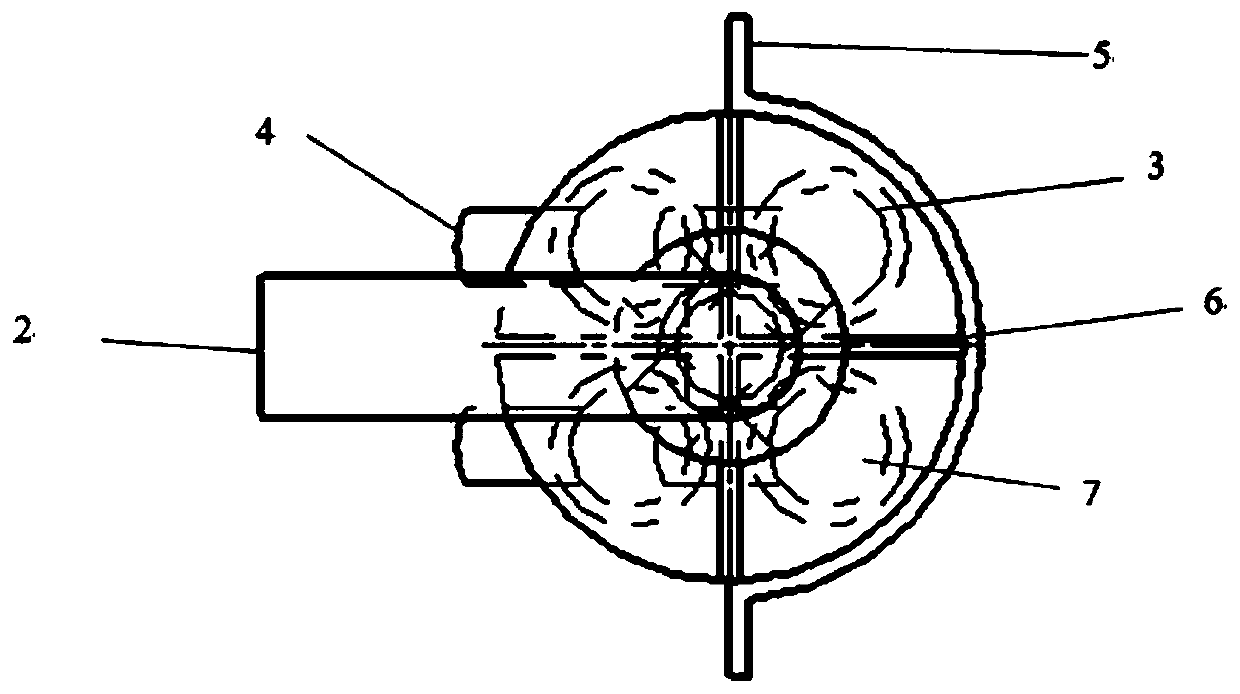

[0038] Such as Figure 6-7 As shown, the remover partition 6 is divided into upper and lower parts, the upper part is well-shaped, and the lower part is cross-shaped. This remover partition 6 divides the spray gun branch pipe 7 into four.

Embodiment 2

[0040] Such as Figure 8-9 As shown, the remover partition 6 is divided into upper and lower parts, the upper part is in the shape of a well, and the lower part is in the shape of a herringbone. This remover partition 6 divides the spray gun branch pipe 7 into three.

Embodiment 3

[0042] Figure 10-11 As shown, the stripper partition 6 is divided into upper and lower parts, and the upper and lower parts are in the shape of a well. This stripper partition 6 divides the spray gun branch pipe 7 into 5.

[0043] The foregoing embodiments reflect that the present invention can flexibly change the shape of the stripping agent partition plate 6 to ensure that it can evenly introduce the stripping agent into the spray gun branch pipe 7 of the stripping agent spray gun 3 with different lengths below, further ensuring that the spraying agent Uniformity of output.

[0044] Such as Figure 12 and Figure 13 ,Compared Figure 9 In the ordinary remover spray gun 3 without remover deflector 6 and without variable diameter, the left side of the ejected remover is less than the right side, and the middle part does not form a turbulent flow zone, which proves that the diffusion does not Perfect, small area, and the follow-up diffusion distribution effect is much diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com