A remote visual all-position automatic argon arc welding device for pipelines

An argon arc welding and all-position technology, which is applied to welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of heavy welding maintenance workload, poor visibility, and high equipment quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

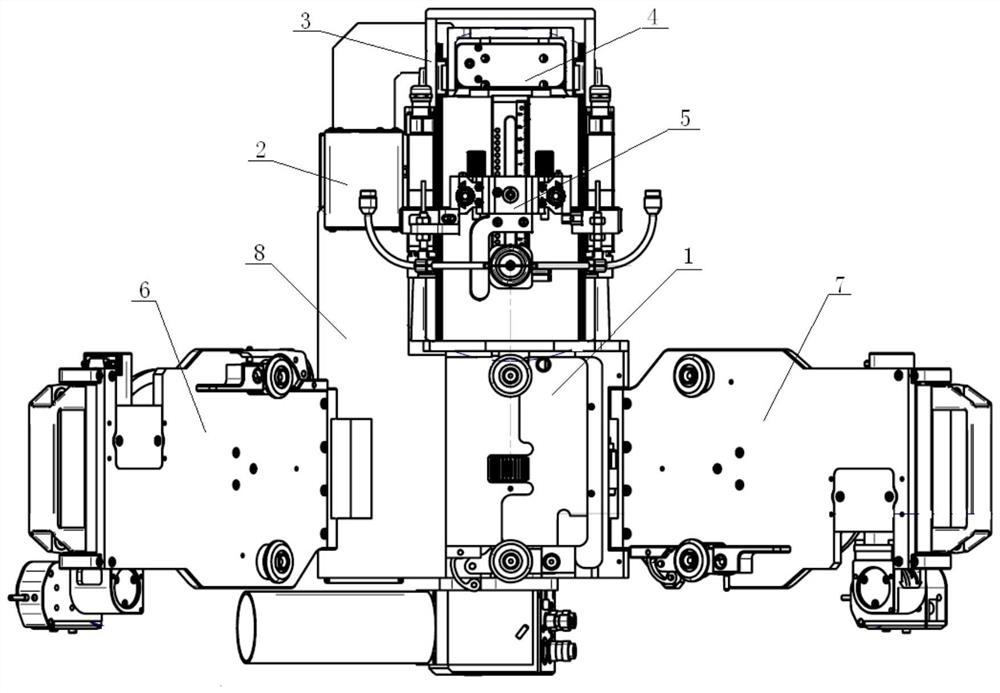

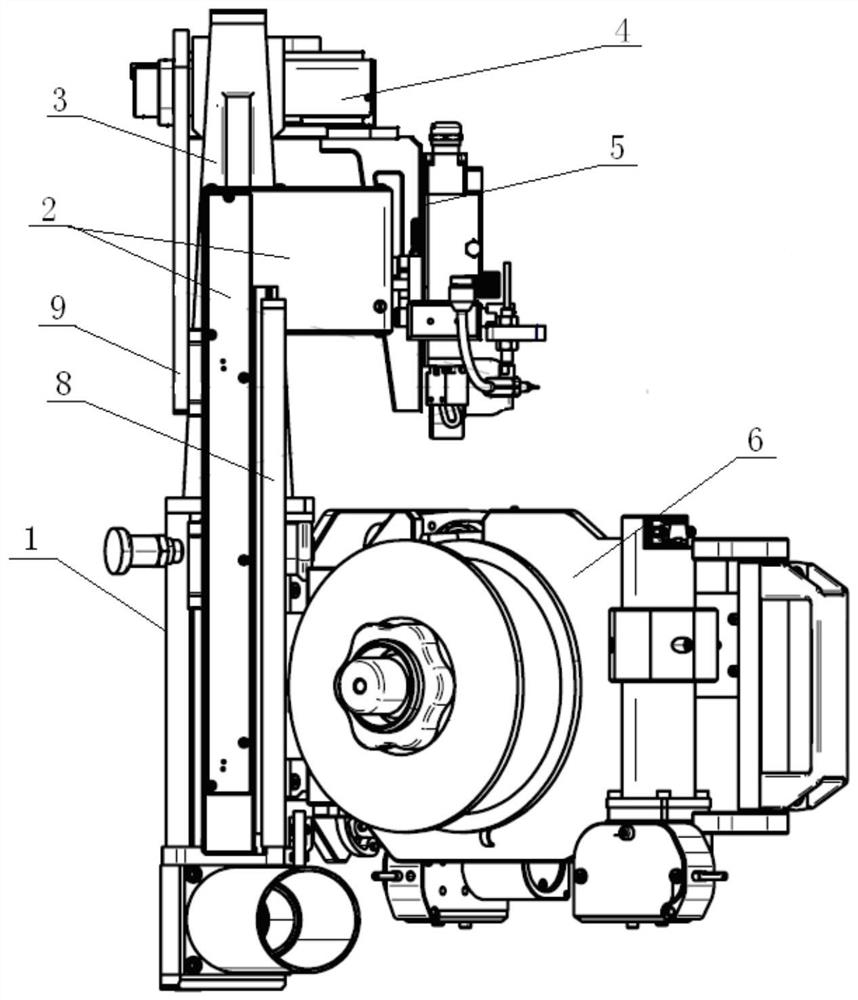

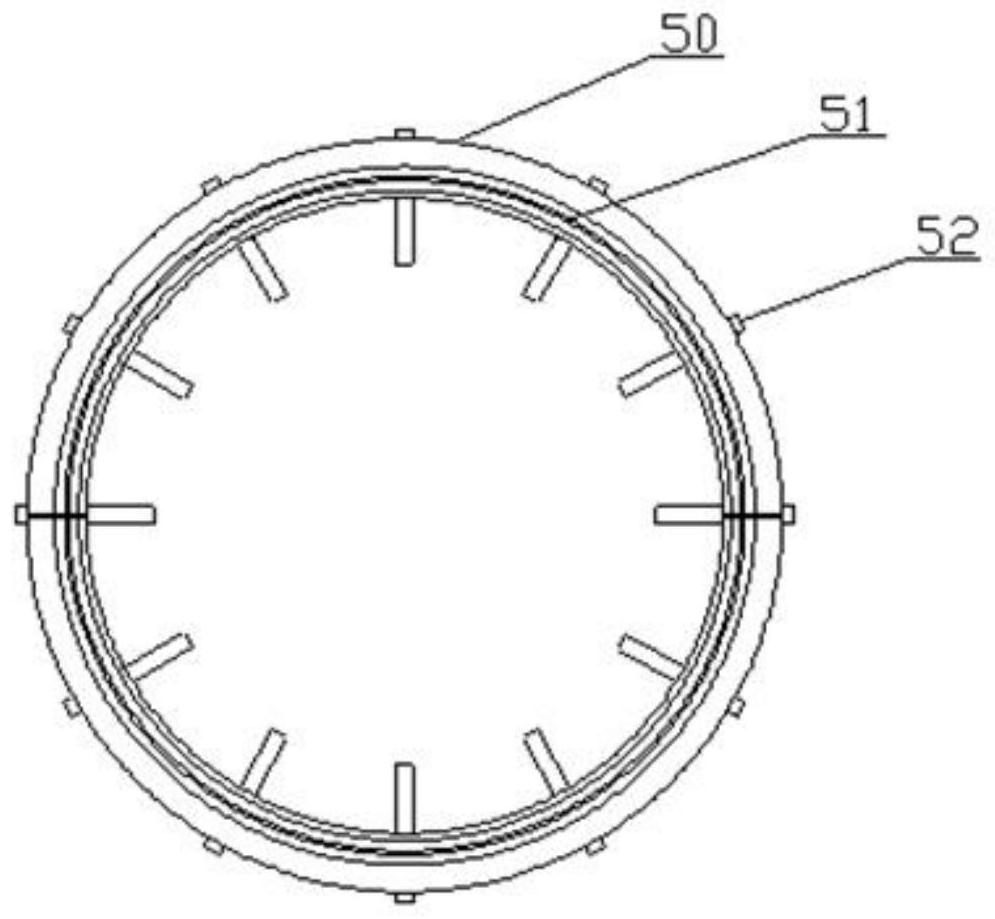

[0045] Such as Figure 1-Figure 13 As shown, a long-distance visual pipeline all-position automatic argon arc welding device includes a welding head and a welding guide rail, as well as a welding power supply, a video monitor and a cooling water tank.

[0046] Such as figure 1 , figure 2 The welding head is composed of a rotary drive module 1, a yaw drive module 2, a yaw drive auxiliary guide rail 3, an AVC swing module 4, a welding torch module 5, a wire feeding module I 6, a wire feeding module II 7, and a head connecting plate 8 , The yaw drive connecting plate 9 constitutes.

[0047] The yaw drive module 2 is fixedly connected to the left side of the rotary drive module 1 and the machine head connecting plate 8 by fastening screws; the left side of the yaw drive auxiliary guide rail 3 is connected to the yaw drive module 2 by fastening screws, The lower part of the pendulum drive auxiliary guide rail 3 is connected to the top of the rotary drive module 1 through fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com