Wire rod for pipeline steel gas shielded welding wire and manufacturing method of wire rod

A technology of wire rod and steel gas, which is applied in the field of wire rod for welding wire and its manufacture, can solve the problem of girth weld welding process and stable welding performance, increased difficulty in controlling weld fracture toughness, backward development of domestic welding materials, and obstacles to girth welding technology Issues such as the high-level development of pipeline steel, to achieve the effect of improving droplet fluidity and realizing all-position automatic welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

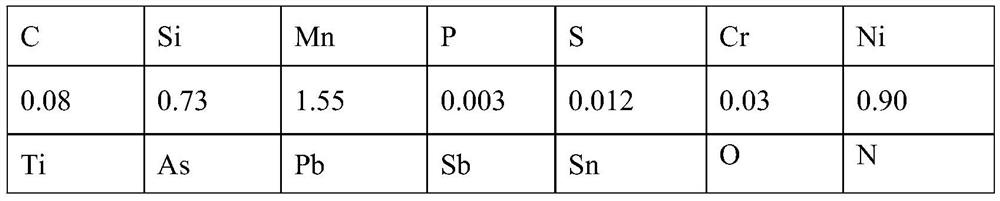

[0045] C Si mn P S Cr Ni 0.075 0.70 1.52 0.002 0.011 0.03 0.92 Ti As Pb Sb sn O N 0.065 0.002 0.002 0.002 0.002 0.0035 0.005

[0046] The balance is Fe and unavoidable impurity elements.

[0047] The surface scanning analysis results of the inclusions in the wire rod with the above components show that the size of the MnS+TiO2 inclusions is stable and less than 5um, and the inclusion density is 49 pieces / mm 2 .

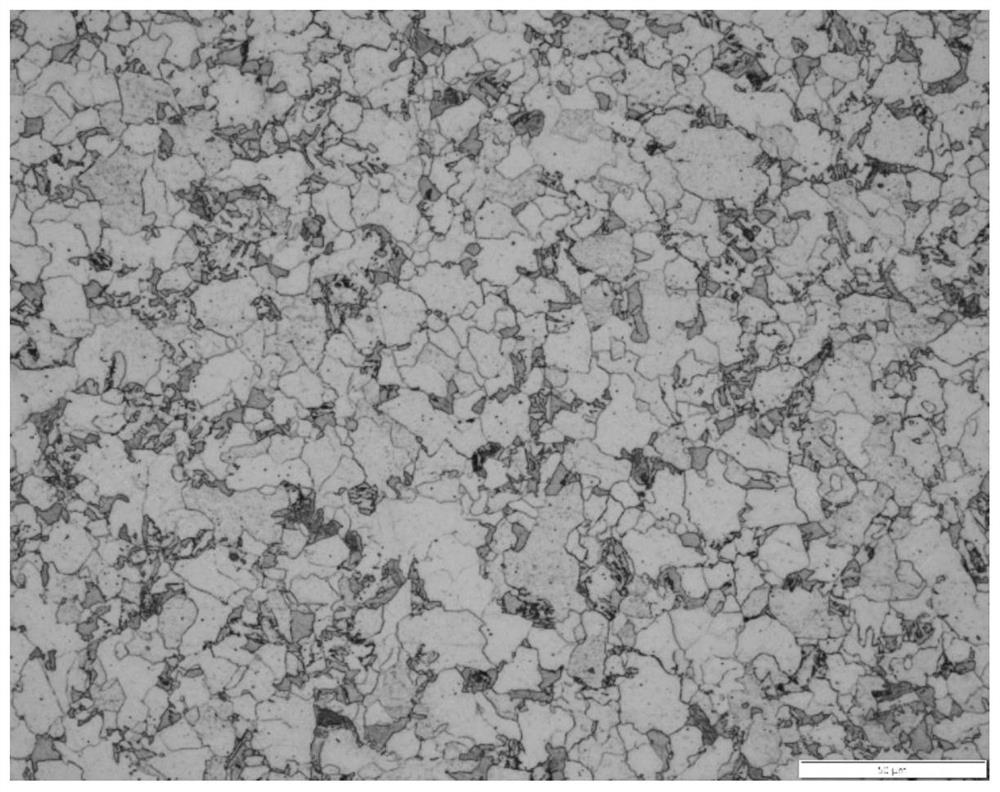

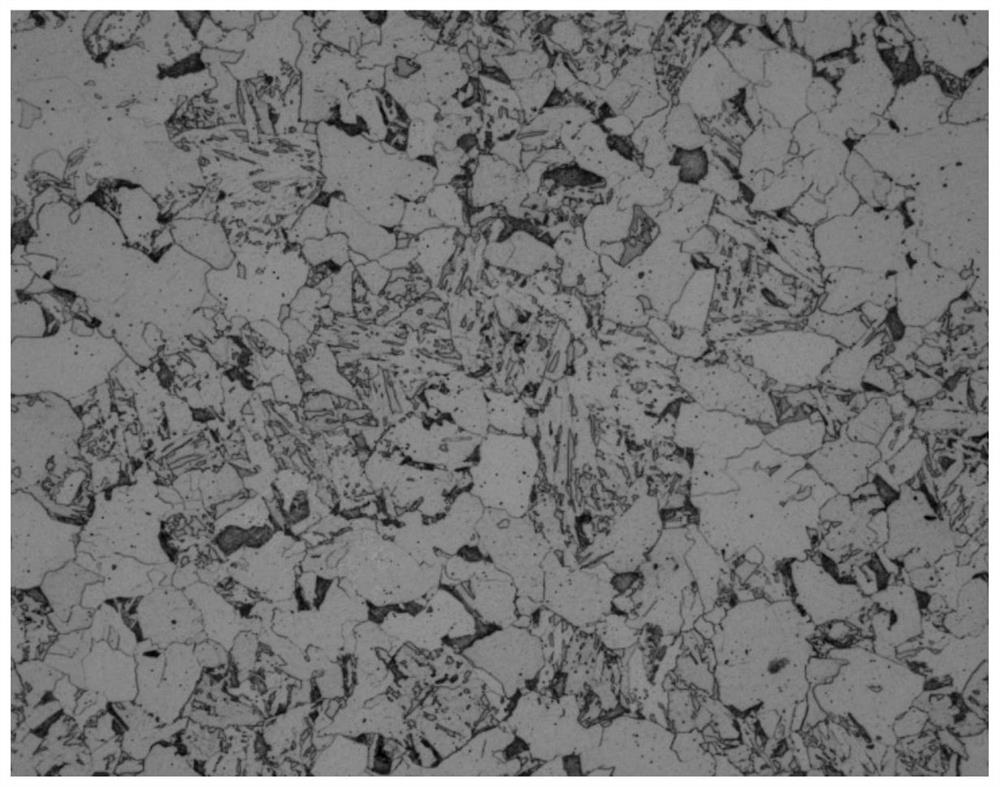

[0048] The hot-rolled wire rod with a diameter of 5.5mm has a tensile strength of 660MPa, a shrinkage of 68%, and a structure of ferrite plus a small amount of pearlite.

Embodiment 2

[0050]

[0051]

[0052] The balance is Fe and unavoidable impurity elements.

[0053] Surface scanning analysis results of wire rod inclusions with the above components MnS+TiO 2 The size of inclusions is stable and less than 5um, and the density of inclusions is 40 pieces / mm 2 .

[0054] The hot-rolled wire rod with a diameter of 5.5mm has a tensile strength of 670MPa, a shrinkage of 70%, and a structure of ferrite plus a small amount of pearlite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com