Efficient preparation device and preparation method of high-performance wave-absorbing material

A technology for absorbing materials and preparation devices, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of difficult mixing evenly, long heating and holding time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing:

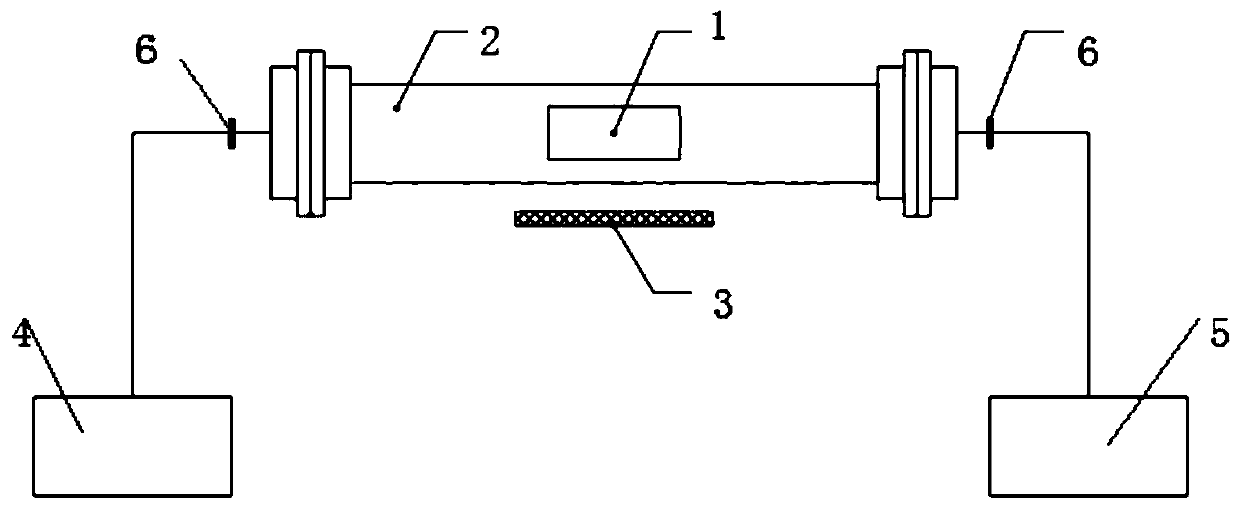

[0051]As shown in the figure, a high-efficiency preparation device for high-performance wave-absorbing materials is characterized in that it is equipped with a graphite container 1, a high-temperature-resistant heating tube 2 and an induction heating part 3, and the high-temperature-resistant heating tube 2 is equipped with a graphite container 1 , the outside of the high-temperature-resistant heating tube is provided with an induction heating part 3, and the high-temperature-resistant heating tube is connected with the vacuum pump 4 and or the inert gas source 5 through the gas guide tube, wherein the high-temperature-resistant heating tube includes a tube body, and the tube body is provided with graphite The container is put into the mouth, and the graphite container is put into the mouth. A sealing cover is provided. The graphite container includes a box body. Described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com