Comprehensive utilization method of Luoyuan red tailings

A technology of tailings and Luoyuan, which is applied in the field of comprehensive utilization of Luoyuan red tailings, can solve the problem of not involving the application of solid waste, and achieve the effect of realizing high value-added resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

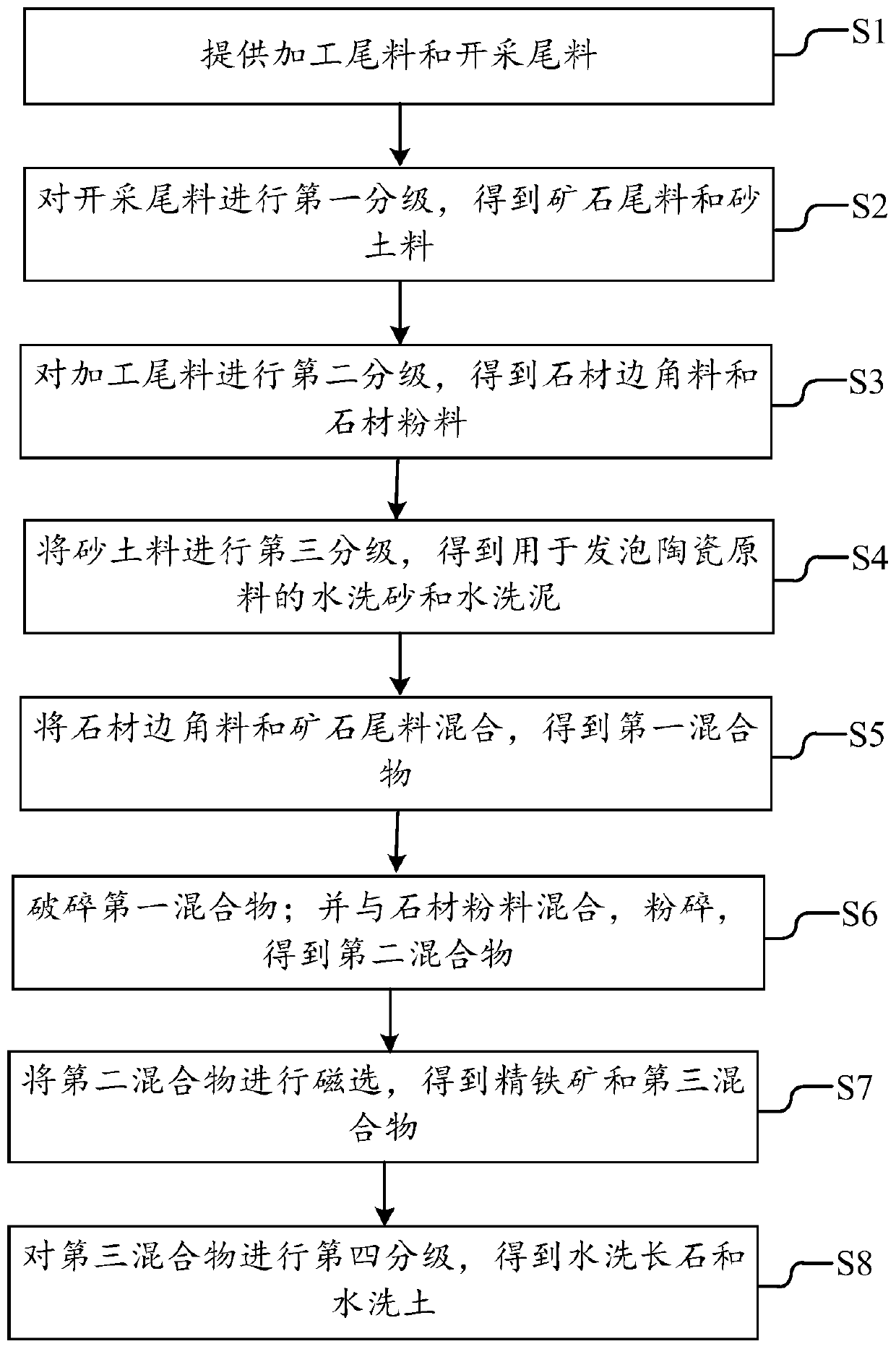

[0091] The present embodiment provides the comprehensive utilization method of Luoyuan red tailings, comprising the following steps:

[0092] (1) Provide processing tailings and mining tailings;

[0093] (2) Sieve the mining tailings with a swinging screen to obtain ore tailings with a particle size > 20mm and sandy soil materials with a particle size ≤ 20mm;

[0094] (3) Use a vibrating screen to screen the processing tailings to obtain stone scraps with a particle size > 5mm and stone powder with a particle size ≤ 5mm;

[0095] (4) Carry out hydrocyclone classification to the sand material, control the overflow particle size to be 250-300 mesh, and obtain washed mud and washed sand;

[0096] (5) mixing stone material scraps and ore tailings to obtain the first mixture;

[0097] (6) Coarsely crushing the first mixture to a particle size of 0.1-3 mm, then adding stone powder, and ball milling to a particle size of 50-100 μm; obtaining the second mixture;

[0098] (7) Carryi...

Embodiment 2

[0105] This embodiment provides a foamed ceramic made from various raw materials obtained in Embodiment 1.

[0106] Its formula is:

[0107] 12.2 parts of washed soil, 65 parts of washed feldspar, 17 parts of washed sand, 3 parts of washed mud, 2 parts of foaming agent, and 0.8 parts of stabilizer.

[0108] Technical testing was carried out on the obtained foamed ceramics, the compressive strength was 8.2MPa, and the bulk density was 208kg / m 3 , The thermal conductivity is 0.09W / m℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com