Ceramic PTC thermistor capable of resisting high pulse overload, and manufacturing method thereof

A technology of thermistor and manufacturing method, applied in resistance manufacturing, resistors with positive temperature coefficient, resistors, etc., can solve the problems of thick film resistors, such as large volume, inability to obtain power, and poor withstand voltage capability, Achieve the effect of good resistance to high voltage power-on shock, uniform chemical composition, and guaranteed voltage resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

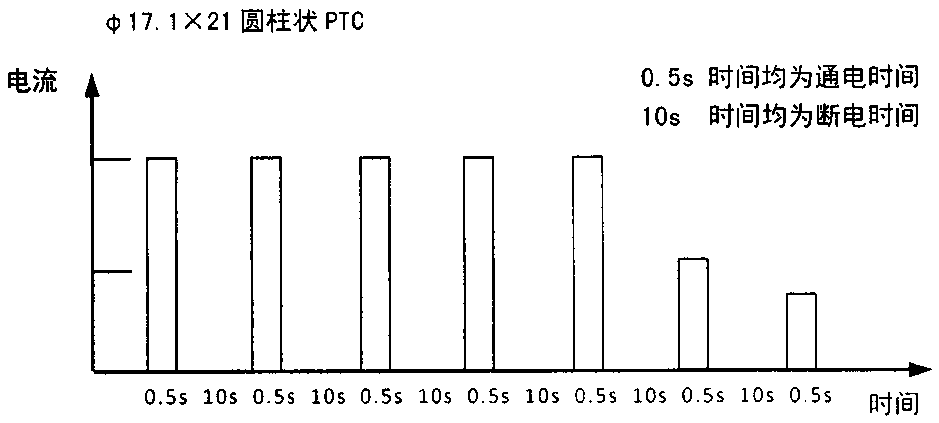

Examples

Embodiment 1

[0042] Raw material molar ratio: BaCO 3 : 0.811mol, CaCO 3 : 0.189mol, TiO 2 : 1.018mol, Y 2 O 3 : 0.0029mol, Mn(NO 3 ) 2 : 0.00082mol, SiO 2 : 0.010mol, Al 2 O 3 : 0.005mol, Si 3 N 4 :0.004mol;

[0043] Put the weighed material into the ball mill jar, and perform ball milling according to the raw material: agate ball: deionized water with insulation resistance greater than 10MΩ=1:1.5:1.5, and the ball mill jar rotates at 50 rpm for 24 hours;

[0044] Dry and press the ball-milled material into a cylindrical shape, heat it up at a heating rate of 150 °C per hour in a high-temperature furnace, heat it up to 1170 °C, and keep it for 3 hours. 200℃, take out and cool to room temperature naturally;

[0045] The pre-sintered and synthesized materials are ball-milled according to the material: agate ball: deionized water = 1:1.5:1.3, the speed of the ball mill tank is 50 rpm, the time is 24 hours, and the insulation resistance of deionized water is required to be greater ...

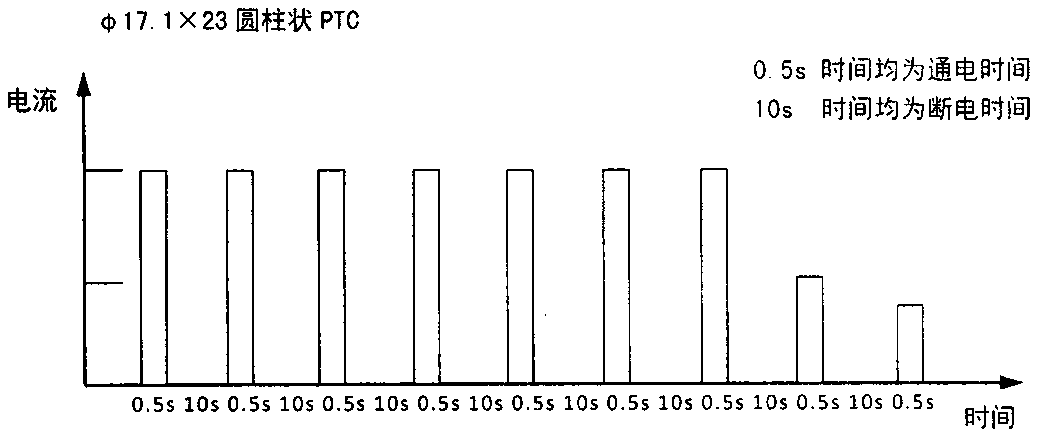

Embodiment 2

[0052] The molar ratio of raw materials is: BaCO 3 : 0.817, CaCO 3 : 0.183, TiO 2 : 1.02, Y 2 O 3 : 0.0031, Mn (NO 3 ) 2 : 0.00084, SiO 2 : 0.013, Al 2 O 3 : 0.007, Si 3 N 4 : 0.005;

[0053] Put the weighed material into the ball mill jar, and perform ball milling according to the raw material: agate ball: deionized water with insulation resistance greater than 10MΩ=1:1.5:1.5, and the ball mill jar rotates at 50 rpm for 24 hours;

[0054] Dry and press the ball-milled material into a cylindrical shape, heat it up at a heating rate of 150 °C per hour in a high-temperature furnace, heat it up to 1170 °C, and keep it for 3 hours. 200℃, take out and cool to room temperature naturally;

[0055] The pre-sintered and synthesized materials are ball-milled according to the material: agate ball: insulation resistance greater than 10MΩ deionized water = 1:1.5:1.3, and the ball milling tank speed is 50 rpm for 24 hours;

[0056] The materials after the above-mentioned second...

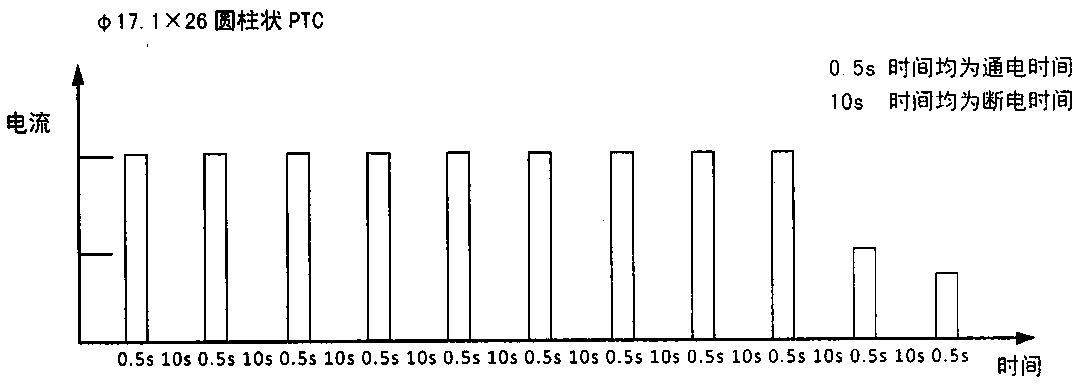

Embodiment 3

[0062] The molar ratio of raw materials is: BaCO 3 : 0.825, CaCO 3 : 0.175, TiO 2 : 1.022, Y 2 O 3 : 0.0033, Mn (NO 3 ) 2 : 0.00096, SiO 2 : 0.011, Al 2 O 3 : 0.009, Si 3 N 4 : 0.004;

[0063] Put the weighed material into the ball mill jar, and perform ball milling according to the raw material: agate ball: deionized water with insulation resistance greater than 10MΩ=1:1.5:1.5, and the ball mill jar rotates at 50 rpm for 24 hours;

[0064] Dry and press the ball-milled material into a cylindrical shape, heat it up at a heating rate of 150 °C per hour in a high-temperature furnace, heat it up to 1170 °C, and keep it for 3 hours. 200℃, take out and cool to room temperature naturally;

[0065] The pre-fired and synthesized materials are ball-milled according to the material: agate balls: deionized water with insulation resistance greater than 10MΩ = 1:1.5:1.3, the speed of the ball mill tank is 50 rpm, and the time is 24 hours;

[0066] The above-mentioned materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com