Fingerprint-resistant polyester resin and preparation method thereof

A technology of polyester resin and fingerprint resistance, which is applied in polyester coatings, coatings, powder coatings, etc. It can solve the problems of easy rubbing off, different functions and uses, and metal powder coatings are not wear-resistant, and achieve good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

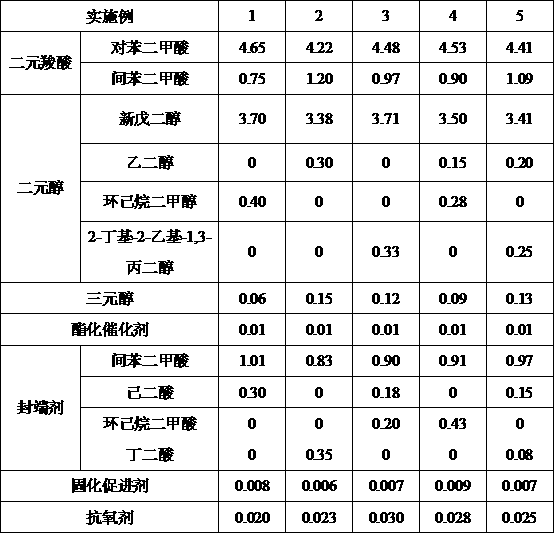

[0020] A handprint-resistant polyester resin, its raw material components and their quality are shown in Table 1.

[0021] Preparation of polyester resin:

[0022] A. Put the formulated amount of dihydric alcohol and trihydric alcohol into the reactor, heat the reactor to 95°C and start stirring, then put in the formulated amount of dicarboxylic acid and esterification catalyst, slowly raise the temperature to 246°C, and maintain the reaction until The acid value is 7.9mgKOH / g;

[0023] B. Lower the temperature of the kettle to 225°C, put in the capping agent, then raise the temperature to 232°C, and maintain the reaction until the acid value is 44.9mgKOH / g;

[0024] C. Under the condition of 228°C, vacuumize at -0.096MPa for 2.5h, then lower the temperature of the kettle to 200°C, put in curing accelerator and antioxidant, and keep it for 18min.

Embodiment 2

[0026] A handprint-resistant polyester resin, its raw material components and their quality are shown in Table 1.

[0027] Preparation of polyester resin:

[0028] A. Put the formulated amount of dihydric alcohol and trihydric alcohol into the reactor, heat the reactor to 93°C and start stirring, then put in the formulated amount of dicarboxylic acid and esterification catalyst, slowly raise the temperature to 248°C, and maintain the reaction until The acid value is 8.5mgKOH / g;

[0029] B. Lower the temperature of the kettle to 227°C, put in the capping agent, then raise the temperature to 236°C, and maintain the reaction until the acid value is 45.5mgKOH / g;

[0030] C. Under the condition of 229°C, vacuumize at -0.097MPa for 2.2h, then lower the temperature of the kettle to 205°C, put in curing accelerator and antioxidant, and keep it for 20min.

Embodiment 3

[0032] A handprint-resistant polyester resin, its raw material components and their quality are shown in Table 1.

[0033] Preparation of polyester resin:

[0034] A. Put the formulated amount of dihydric alcohol and trihydric alcohol into the reactor, heat the reactor to 108°C and start stirring, then put in the formulated amount of dicarboxylic acid and esterification catalyst, slowly raise the temperature to 247°C, and maintain the reaction until The acid value is 9.1mgKOH / g;

[0035] B. Lower the temperature of the kettle to 220°C, put in the capping agent, then raise the temperature to 233°C, and maintain the reaction until the acid value is 43.8mgKOH / g;

[0036] C. Under the condition of 231°C, vacuumize at -0.094MPa for 2.8h, then lower the temperature of the kettle to 195°C, put in curing accelerator and antioxidant, and maintain for 22min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com