A kind of compound shot-peening strengthening method for gear division and spiral bevel gear

A spiral bevel gear and shot peening technology, which is applied in the field of spiral bevel gear and gear partition composite shot peening, can solve the problem of tooth surface fatigue resistance, wear resistance, waste of manpower and material resources, and inconsistent gear surface performance and other problems, to achieve the effect of good wear resistance and fatigue resistance, strong wear resistance and fatigue resistance, and shorten the shot peening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained without creative labor.

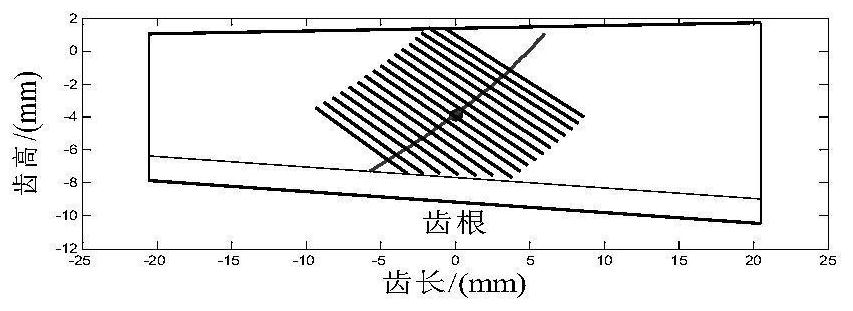

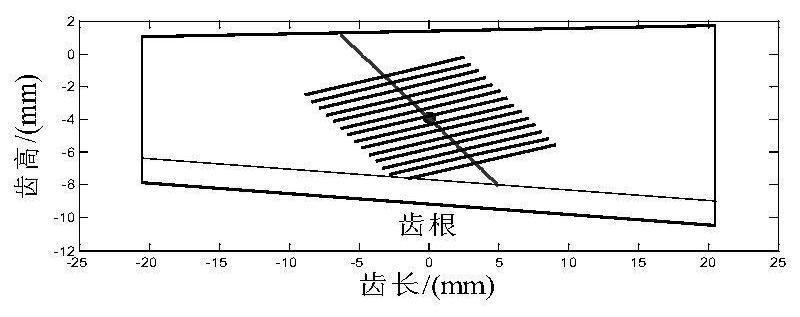

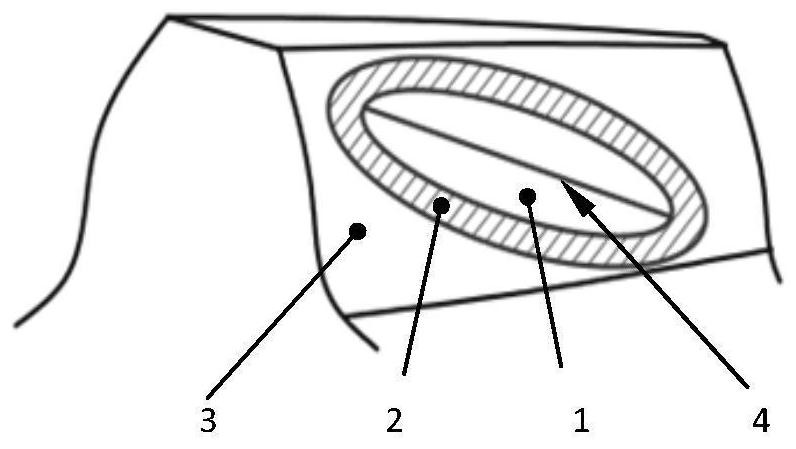

[0025] In this embodiment, the coil gear sub-gear is used in the heavy-duty vehicle installed bicycle, considering the high contact stress of the gear, and since the high axial load of the small wheel is large, it is easy to slip. Creating edge and tubing contact, resulting in problems with short wear, in particular reversing surface), short fatigue life, intended to work with the vehicle with the vehicle with the vehicle with the vehicle with the same life, according to the gear and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com