Cobble stratum soil nail drilling equipment

A technology for drilling equipment and formations, applied in drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of high cost, high cost, and failure of bolters to drill holes smoothly, and achieve low cost, simple machinery, and reduced costs. Effect of Hole Difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

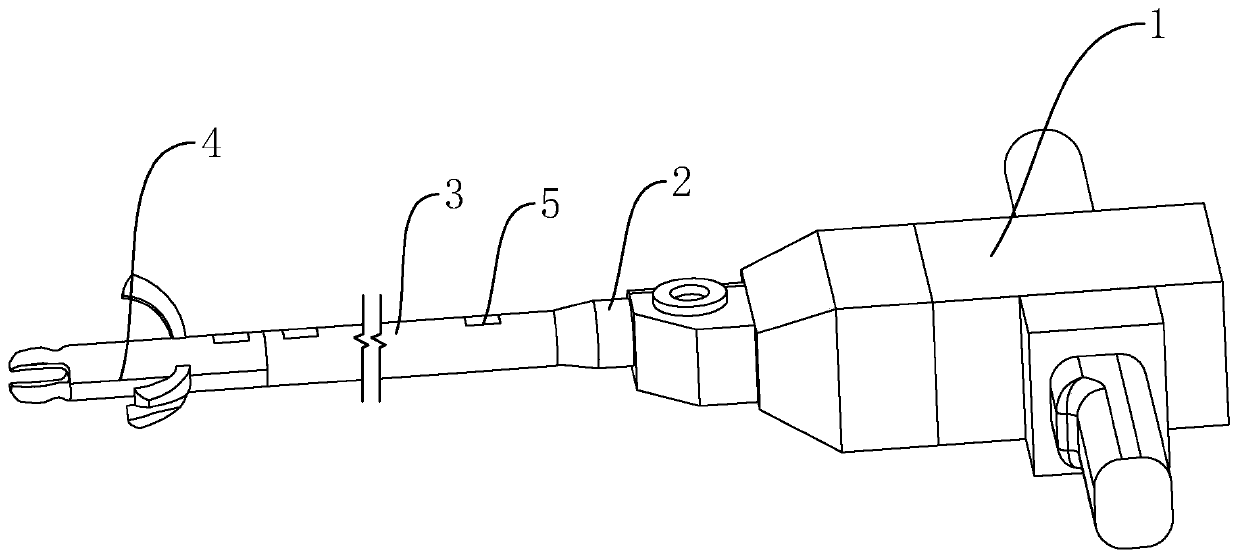

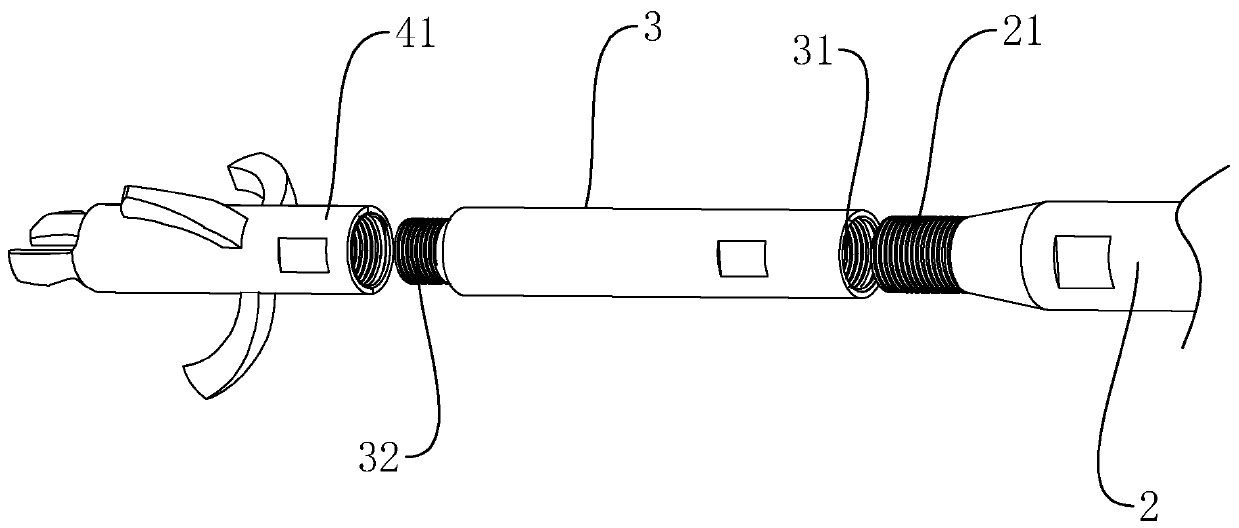

[0039] refer to figure 1 , is pebble stratum soil nail drilling equipment disclosed by the present invention, comprises water drilling rig 1, and output shaft 2 is connected with transmission on water drilling rig 1, and drill rod 3 is screwed on output shaft 2, and drill rod 3 is multi-section, each drill Rod 2-4m, thereby can select the drilling rod 3 of different lengths according to different drilling depths. The adjacent drill rods 3 are threaded. One end of the drill rod 3 away from the water drilling rig 1 is screwed with a drill bit 4 .

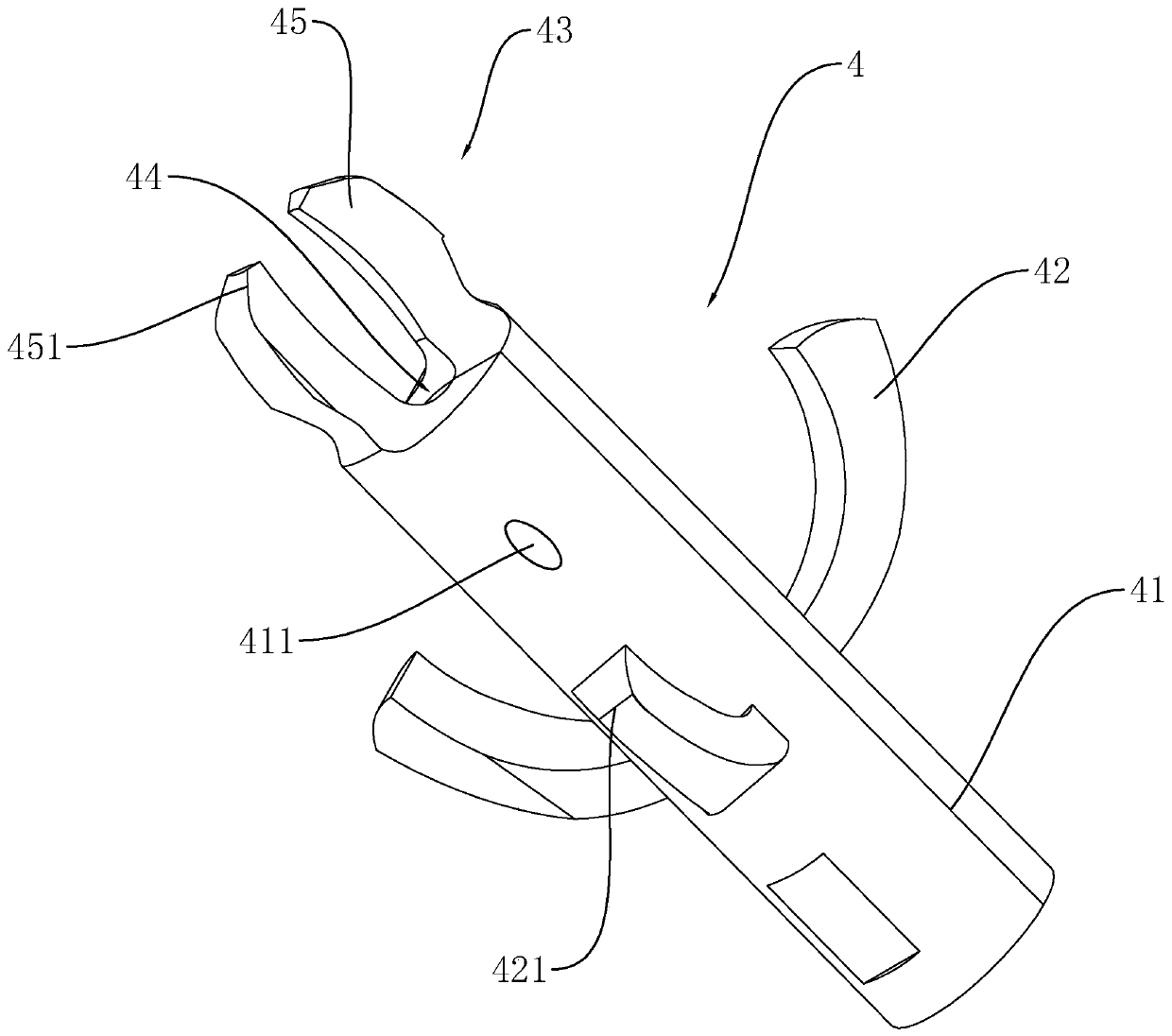

[0040] refer to figure 2 , the drill bit 4 comprises a rod body 41, a plurality of drill teeth 42 fixed on the peripheral surface of the rod body 41 at uniform intervals and a drilling portion 43 fixed at the end of the rod body 41, the drill teeth 42 are at least three, and the drilling portion 43 It is U-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com