Explosion-proof door for waste heat boiler and waste heat boiler

A technology of waste heat boiler and explosion-proof door, which is applied to steam boiler components, steam boilers, steam boiler accessories, etc., to achieve good safety and stable operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

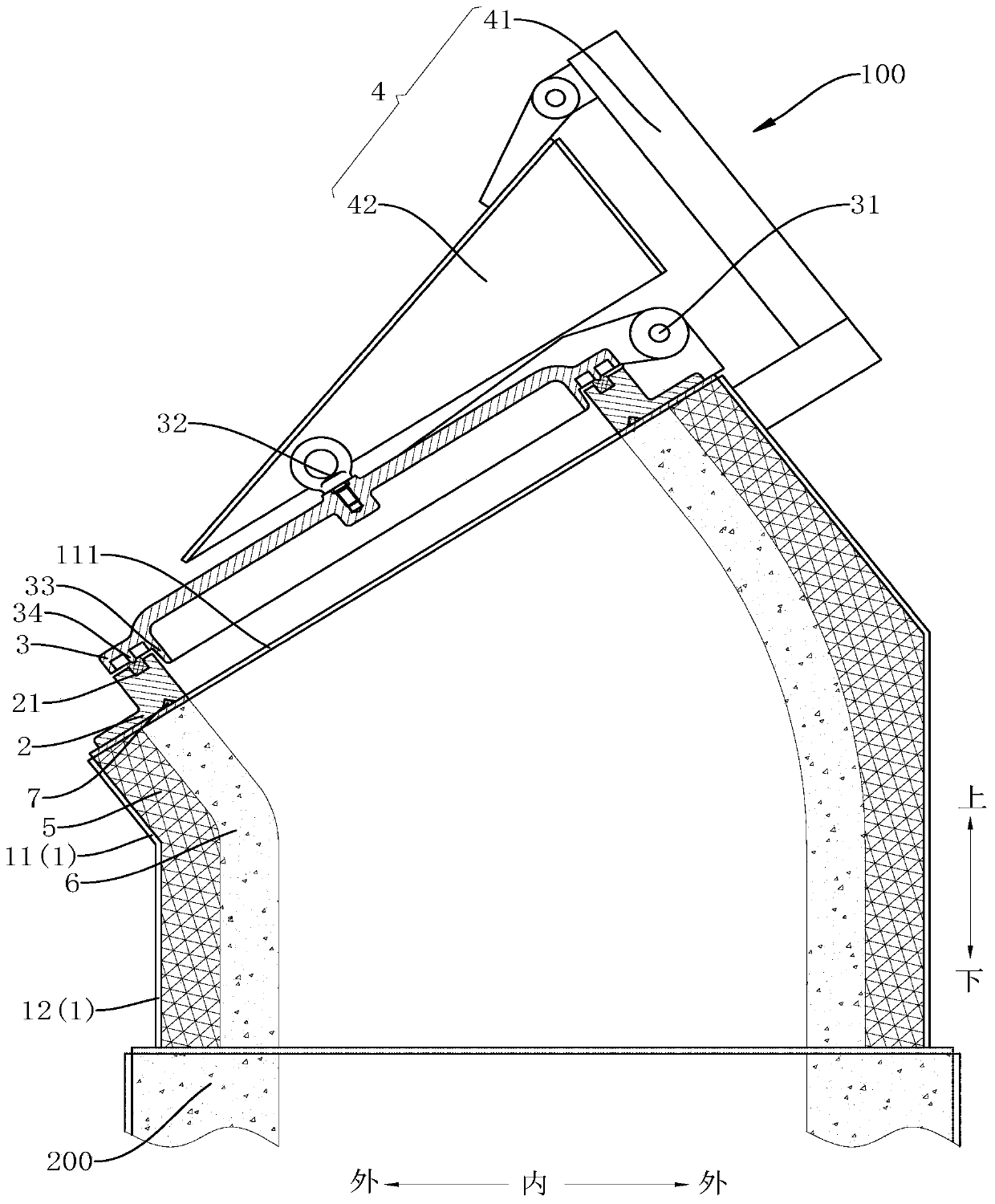

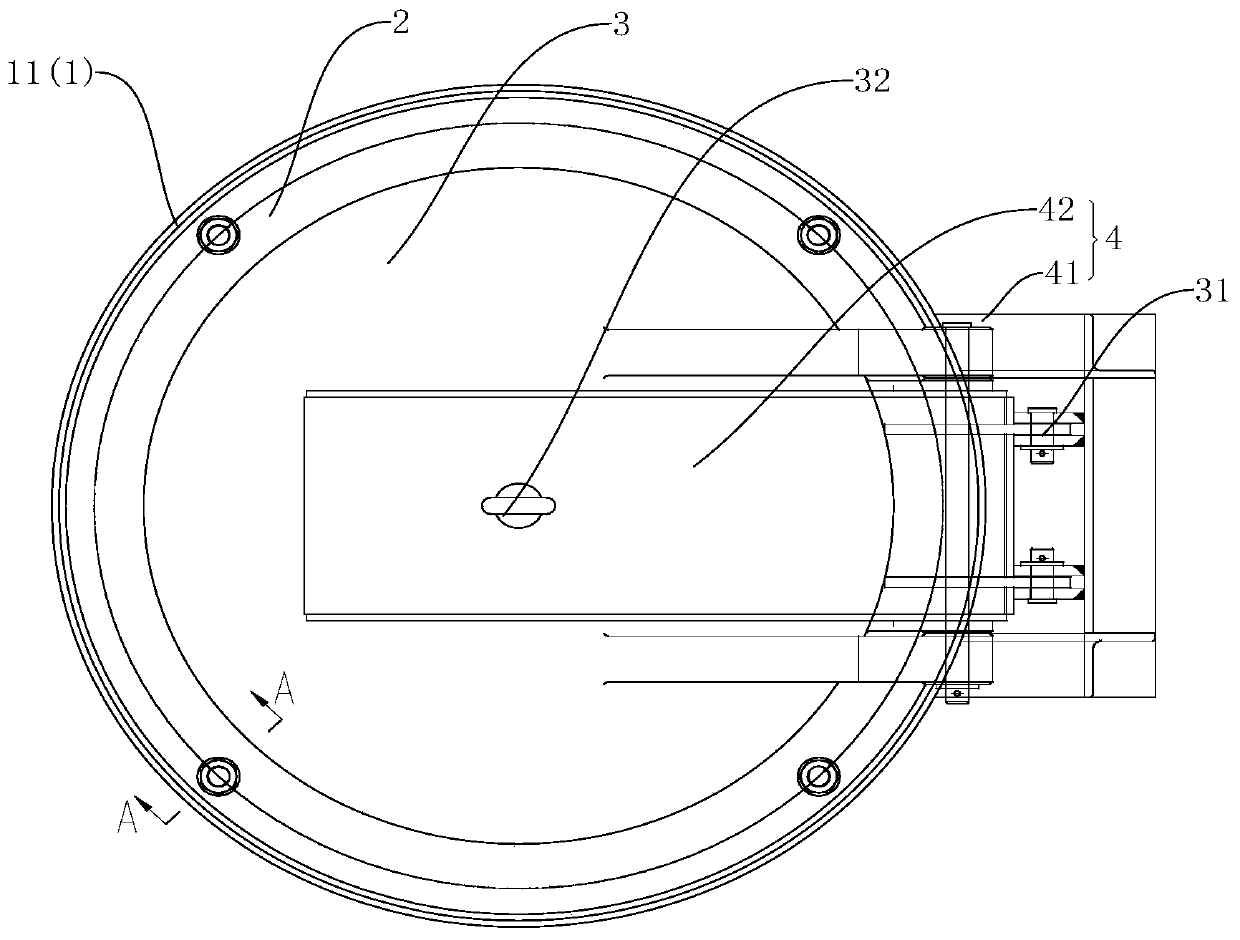

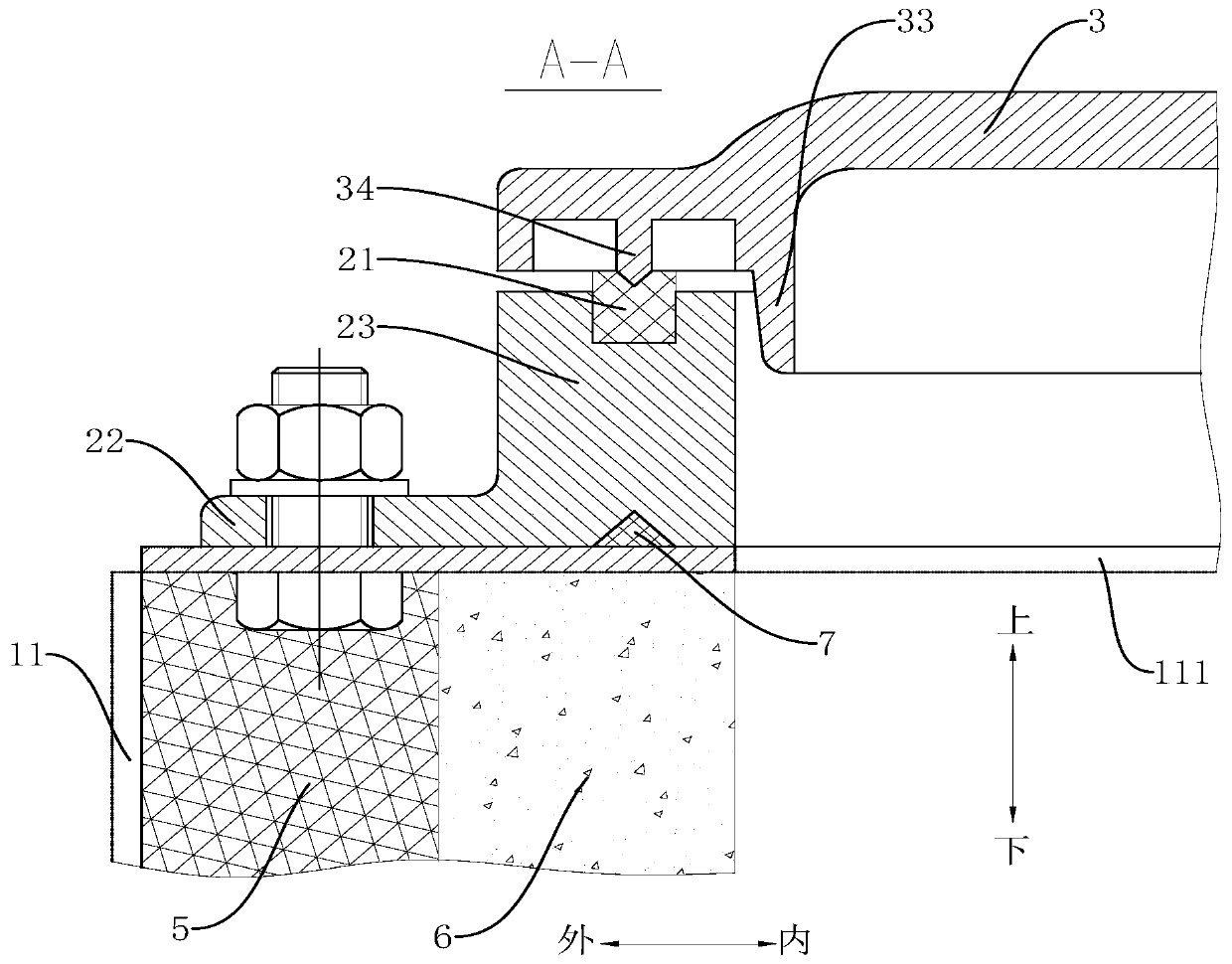

[0080] An explosion-proof door 100 for a waste heat boiler, comprising: an explosion-proof door connecting pipe 1 , an explosion-proof door frame 2 , an explosion-proof door body 3 , a limit assembly 4 , an insulation layer 5 , a heat-resistant layer 6 , and an asbestos seal 7 .

[0081] Such as figure 1 As shown, the explosion-proof door connecting pipe 1 of the present invention is integrally formed into a cylindrical structure, which is installed in the turning area of the ceiling flue gas flow direction of the waste heat boiler ascending flue 200 . A group of ceiling pipes are arranged at the inlet end of the explosion-proof door connecting pipe 1 as cooling pipes.

[0082] Such as figure 1 and Figure 7 As shown, the explosion-proof door connecting pipe 1 has a wall thickness of about 5 mm. The explosion-proof door connecting pipe 1 includes a cylindrical straight part 12 and a cylindrical bending part 11. The axis of the straight part 12 coincides with the axis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com