Friction plate impact plastic deformation test system

A test system and friction plate technology, which is applied in the field of test systems for simulating the impact and plastic deformation of friction plates, can solve problems such as low data reliability, fatigue fracture, time-consuming and costly, and achieve high safety by avoiding accidental touch by personnel , Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

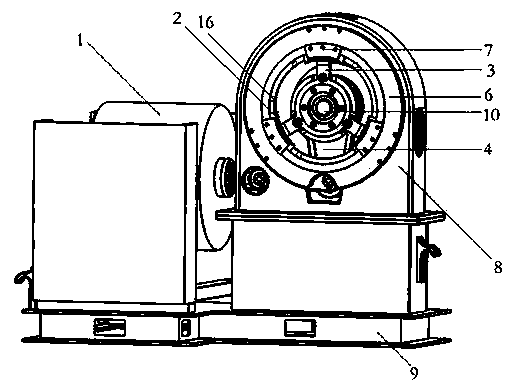

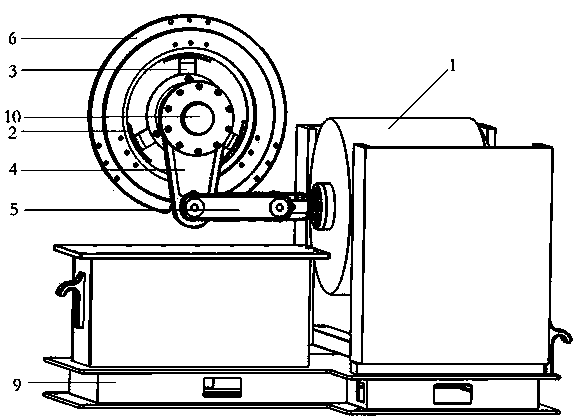

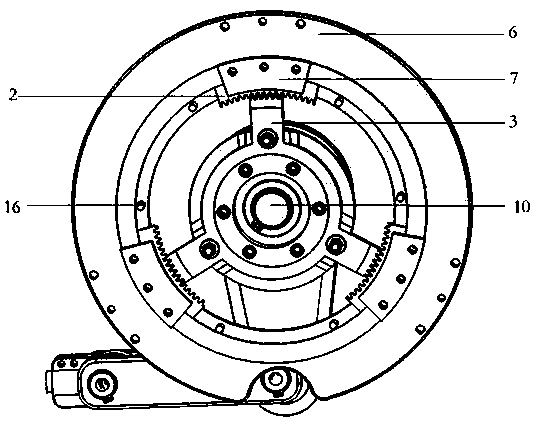

[0034] as attached figure 1 As shown, the present invention provides a friction plate impact plastic deformation test system, which includes an impact plastic deformation simulation device, a strain signal acquisition module, a strain signal processing module, a high-speed camera, a digital image processing module, and a display and control module;

[0035] The impact plastic deformation simulation device can directly simulate the contact plastic deformation load caused by the impact contact stress, and reproduce the contact plastic deformation fatigue damage of the tooth surface of the friction plate;

[0036] The high-speed camera takes pictures of the movement process of the meshing tooth surface under the condition of high-speed rotation;

[0037] The digital image processing module conducts digital image technology analysis on the motion process pict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com