Neutron imaging method for natural gas hydrate sediment triaxial mechanical test

A technology of hydrate sediments and triaxial mechanics, which can be used in the application of stable tension/pressure to test the strength of materials, scientific instruments, and material analysis using wave/particle radiation, which can solve the problem of limited imaging accuracy of gas hydrate phase states. , difficult to apply, limited ability of X-ray to penetrate the high pressure cavity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

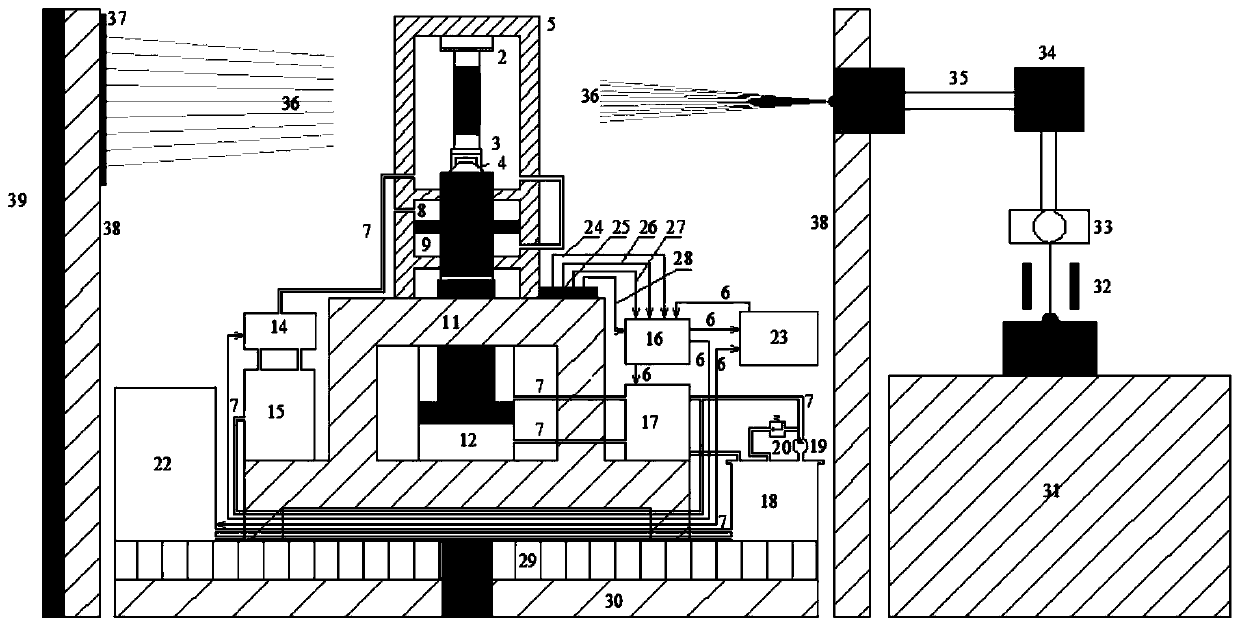

[0010] 1. Place the sample 1 between the upper block 2 and the lower block 3, center it, record the length and position of the sample, and package the three-axis cylinder 5;

[0011] 2. Adjust the position of the cold neutron ray source on the detector column 38, adjust the positions of the detector 37 and the detector column 38, and ensure that the cold neutron ray 36 can completely cover the sample 1 and reach the detector 37;

[0012] 3. Open the control computer 23, open the multi-channel digital closed-loop servo controller 16, and connect the control computer 23 to maintain data communication with the multi-channel digital closed-loop servo controller 16;

[0013] 4. Set the sampling parameters of each sensor in the physical quantity measurement part on the control computer 23, set the force loading or displacement loading parameter waveform in the test process, start the high-precision digital turntable, and start the rock mechanics neutron imaging test;

[0014] 5. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com