Electro-hydraulic servo pressure infiltration device

An electro-hydraulic servo and platen technology, which can be used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. To achieve the effect of simple structure, guaranteed stability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

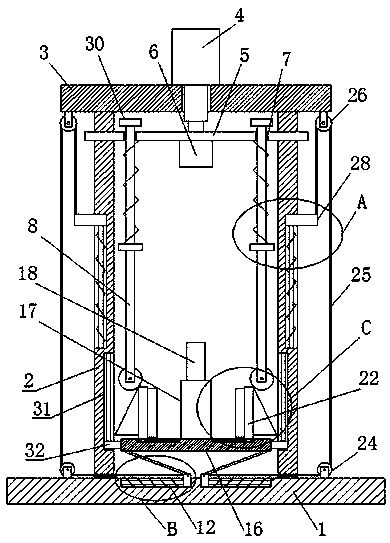

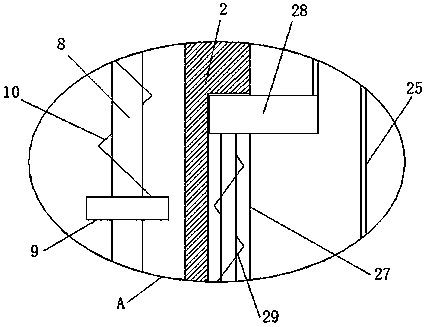

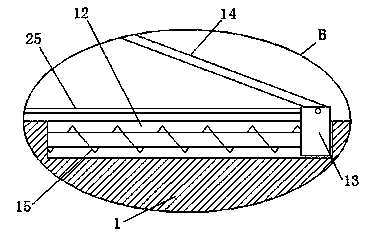

[0029] refer to Figure 1-5 , an electro-hydraulic servo pressure seepage device, comprising a workbench 1, two support plates 2 are fixedly installed on the top of the workbench 1, a top plate 3 is fixedly installed on the top of the two support plates 2, and a hydraulic pressure is fixedly installed on the top of the top plate 3 Cylinder 4, the piston rod of hydraulic cylinder 4 extends to the bottom of the top plate 3 and is fixedly installed with a pressure plate 5, the bottom of the pressure plate 5 is provided with a pressure plate 6, and the top of the workbench 1 is provided with two transmission grooves 12, two transmission grooves 12 The transmission block 13 is slidingly installed inside, the top of the transmission block 13 extends to the top of the workbench 1, and the transmission rod 14 is installed on the transmission block 13, and the same lifting plate 16 is installed on the top of the two transmission rods 14. A cylinder 17 is provided on the top of the lift...

Embodiment 2

[0040] refer to Figure 1-5 , an electro-hydraulic servo piezo-infiltration device, comprising a workbench 1, two support plates 2 are fixedly installed on the top of the workbench 1 by welding, and a top plate 3 is fixedly installed on the top of the two support plates 2 by welding, and the top of the top plate 3 A hydraulic cylinder 4 is fixedly installed by welding. The piston rod of the hydraulic cylinder 4 extends to the bottom of the top plate 3 and a pressure plate 5 is fixedly installed by welding. Slot 12, two drive slots 12 are slidingly installed with transmission block 13, the top of transmission block 13 extends to the top of workbench 1, and transmission rod 14 is installed on the transmission block 13, and the top of two transmission rods 14 rotates The same lifting plate 16 is installed, the top of the lifting plate 16 is provided with a cylinder 17, the cylinder 17 is provided with a percolation chamber, the top of the cylinder 17 is provided with a plunger 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com