Mould detection device and detection method

A detection device and mold technology, applied in the field of optical detection, can solve the problems of poor measurement, large overall equipment, weak strength, etc., and achieve the effects of flexible design scheme, improved detection efficiency, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

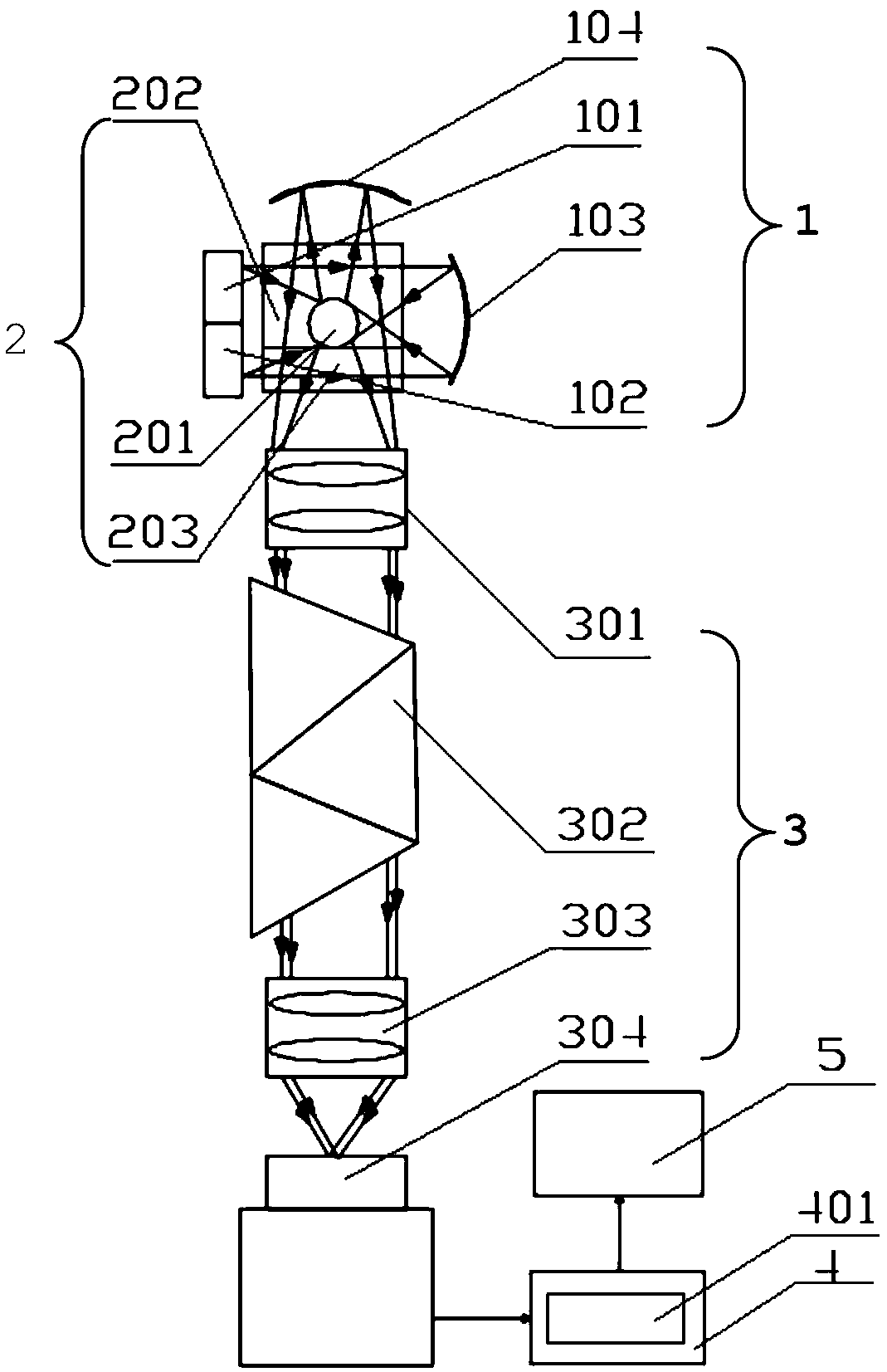

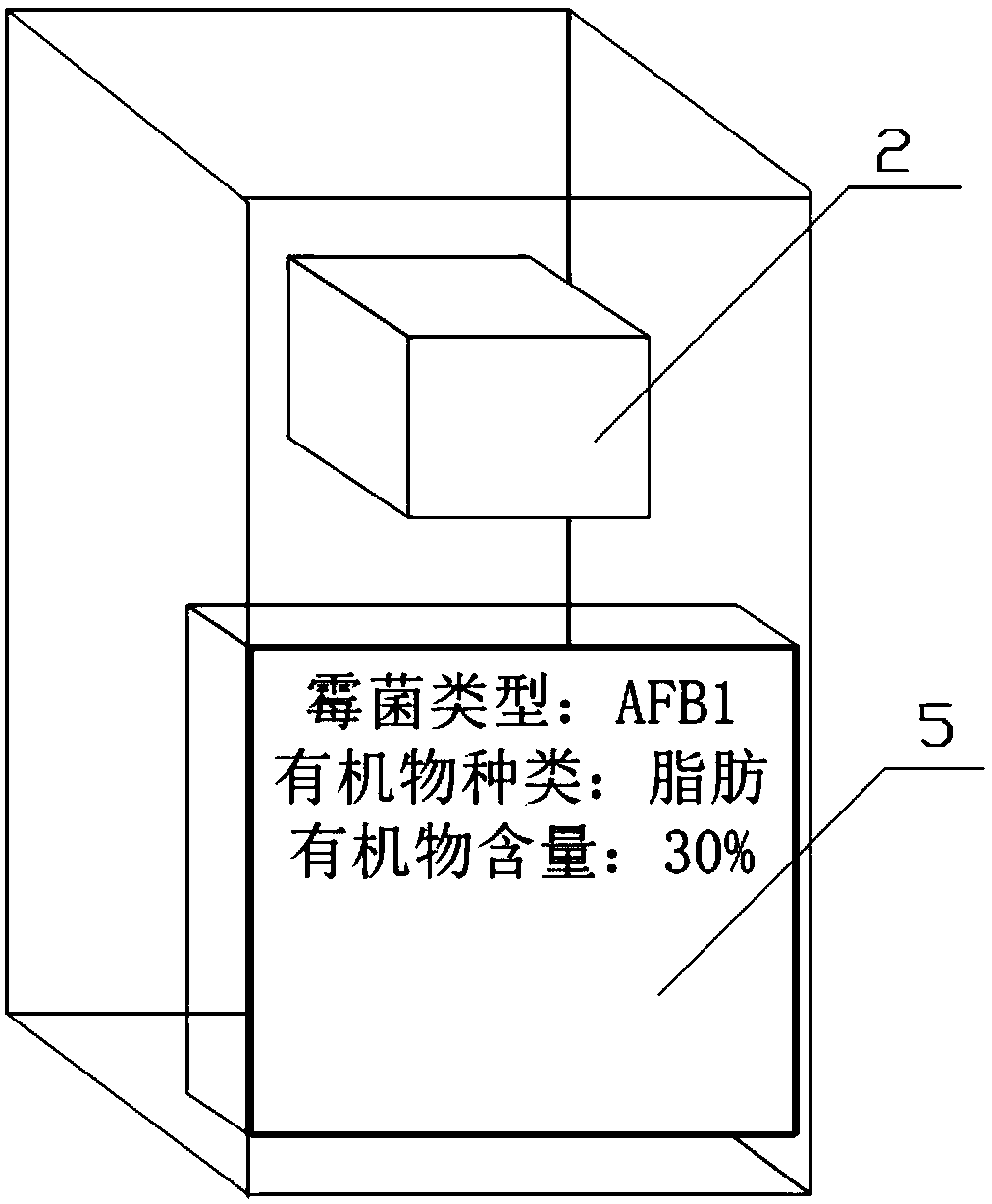

[0036] Example 1: Combining figure 1 and figure 2 Describe this embodiment, the optical structure of a kind of mold detection device of this embodiment is as follows figure 1 As shown, it includes: a detection module 1 , a sample chamber 2 , a detection module 3 and a data processing module 4 .

[0037] The detection module 1 includes an infrared detection sub-module 101, an ultraviolet detection sub-module 102, a first mirror 103 and a second mirror 104, and the infrared detection sub-module 101 is used to emit incident infrared light to excite the The organic matter in the sample 201 emits a specific spectrum, and the ultraviolet detection submodule 102 is used to emit incident ultraviolet light to excite the mold on the surface of the sample 201 to be tested to emit a specific spectrum, and the first reflector 103 is arranged at the incident On the propagation path of the infrared light and the incident ultraviolet light, it is used to change the propagation direction of...

Embodiment 2

[0046] Embodiment 2: A mold detection device of this embodiment is further defined on the basis of the specific embodiment 1. The focus position of the first reflector 103 coincides with the geometric center of the sample 201 to be tested during detection. The effect of such settings It is capable of reflecting and converging all the light emitted by the light source to the surface of the sample 201 to be tested, so as to ensure sufficient illumination.

Embodiment 3

[0047] Embodiment 3: A kind of mold detection device of this embodiment is further defined on the basis of specific embodiment 1. The focus position of the second reflector 104 coincides with the geometric center of the sample to be tested 201 during detection, so that the sample to be tested After being reflected by the second reflector 104, the scattered light at 201 can enter the subsequent optical module at a smaller angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com