Online prediction and positioning method for internal crack of slab continuous casting

A technology of continuous casting of internal cracks and slabs, applied in the direction of material thermal conductivity, material thermal development, etc., can solve the problems of inability to accurately locate the casting slab, low accuracy rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

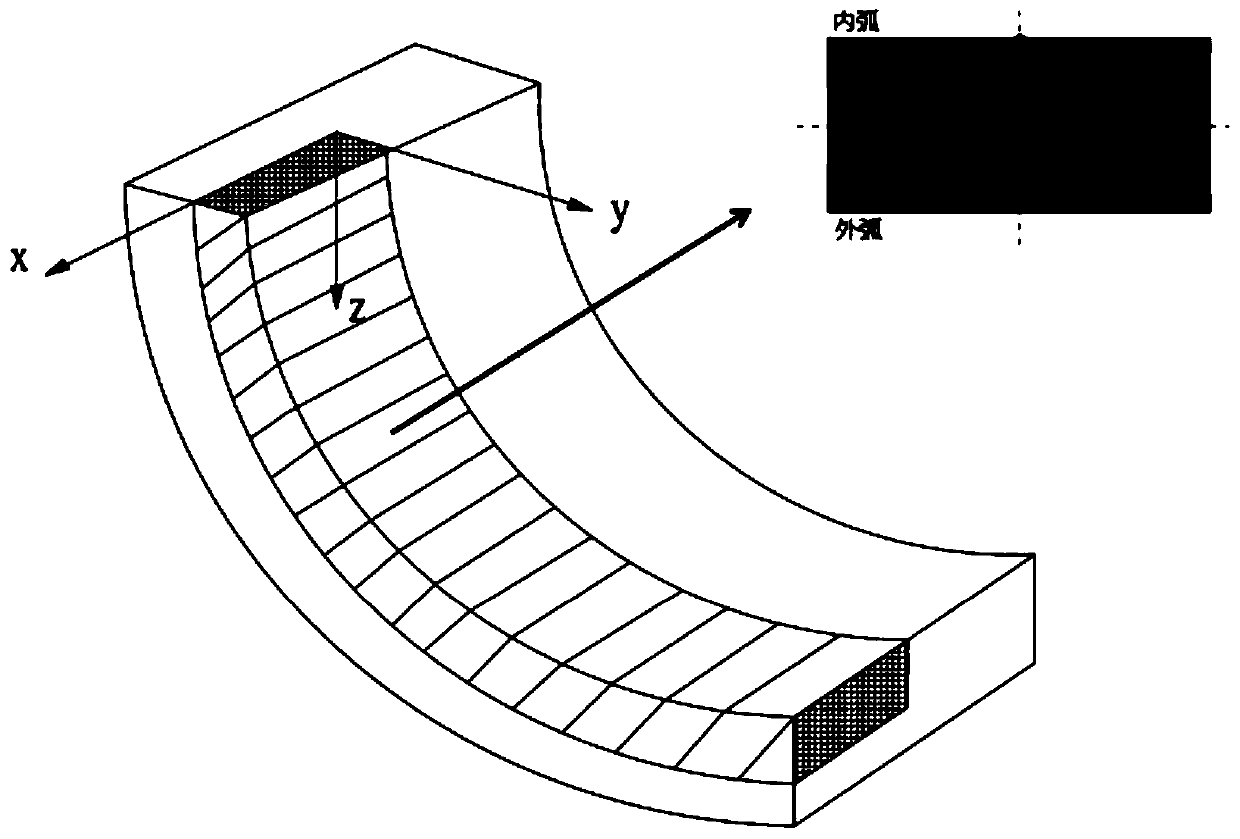

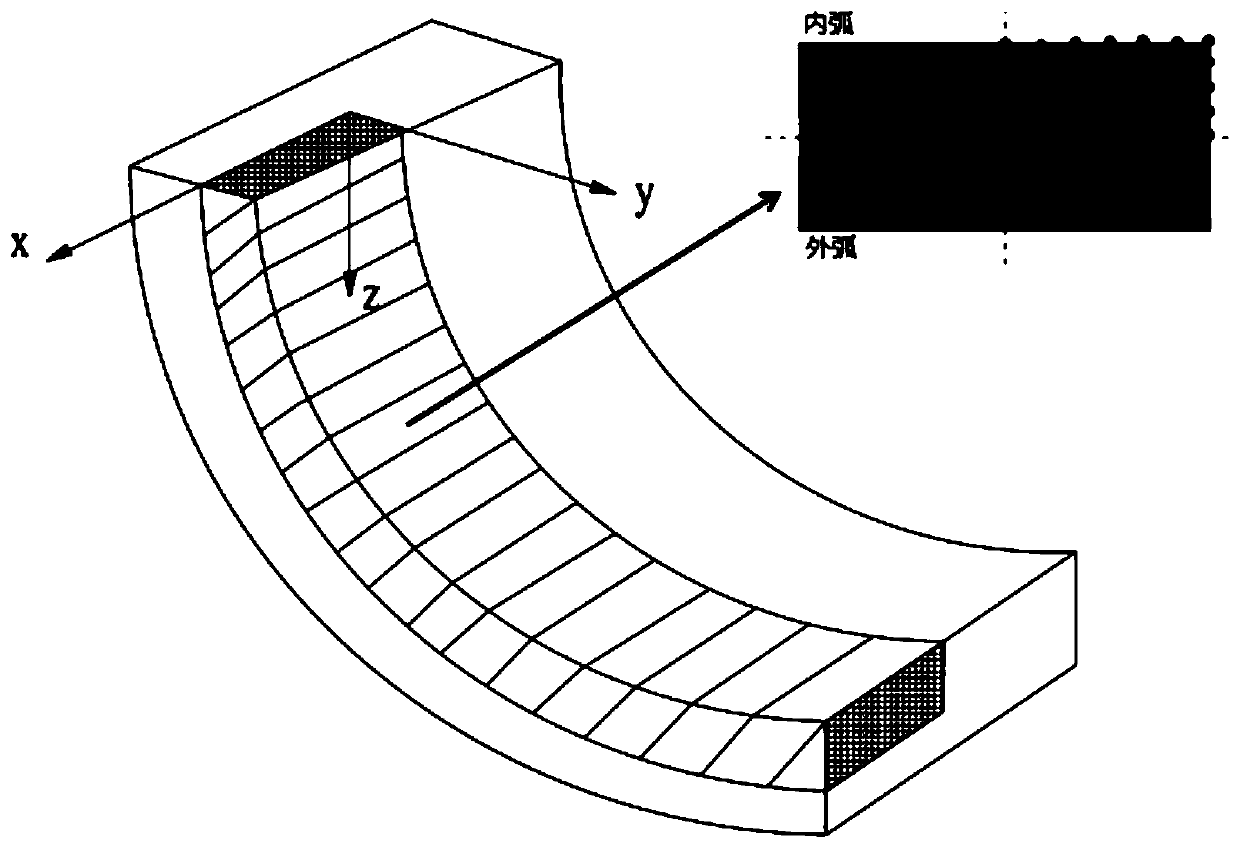

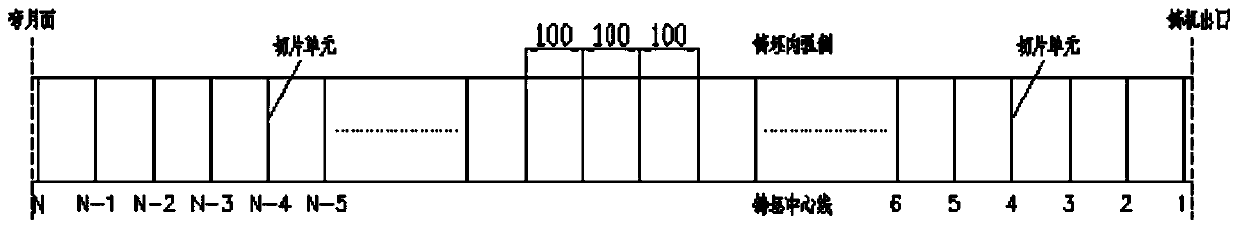

[0078] The slab continuous casting machine in a steel factory has a production section of 250mm×1870mm casting slab, the production steel type is Q235, the working casting speed is 1.0m / min, and the casting temperature is 1539℃. Changes in the two-dimensional temperature field of the slice unit, real-time online calculation of the belly strain, bending / straightening strain, and misalignment strain at each nip roller.

[0079] Described method steps are as follows:

[0080] 1. Model parameter initialization

[0081] Start the monitoring model based on the real-time online three-dimensional temperature field simulation calculation of the continuous casting machine, initialize the structural parameters of the casting machine: roll column data information, secondary cooling zone information, crystallizer information, etc.; temperature field simulation calculation parameters: space step, time Step length, slice spacing, simulation calculation cycle; offline test parameters of nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com