Transmission arrangement for a transmission of a vehicle or the like

A kind of transmission assembly and other technologies, which are applied to vehicle components, the layout of multiple different prime movers of general power plants, hybrid vehicles, etc., can solve the problems of decoupling that cannot guarantee the uniformity of rotation, and cannot be transferred immediately, etc., to achieve Compact axial structural space, improve service life and avoid noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

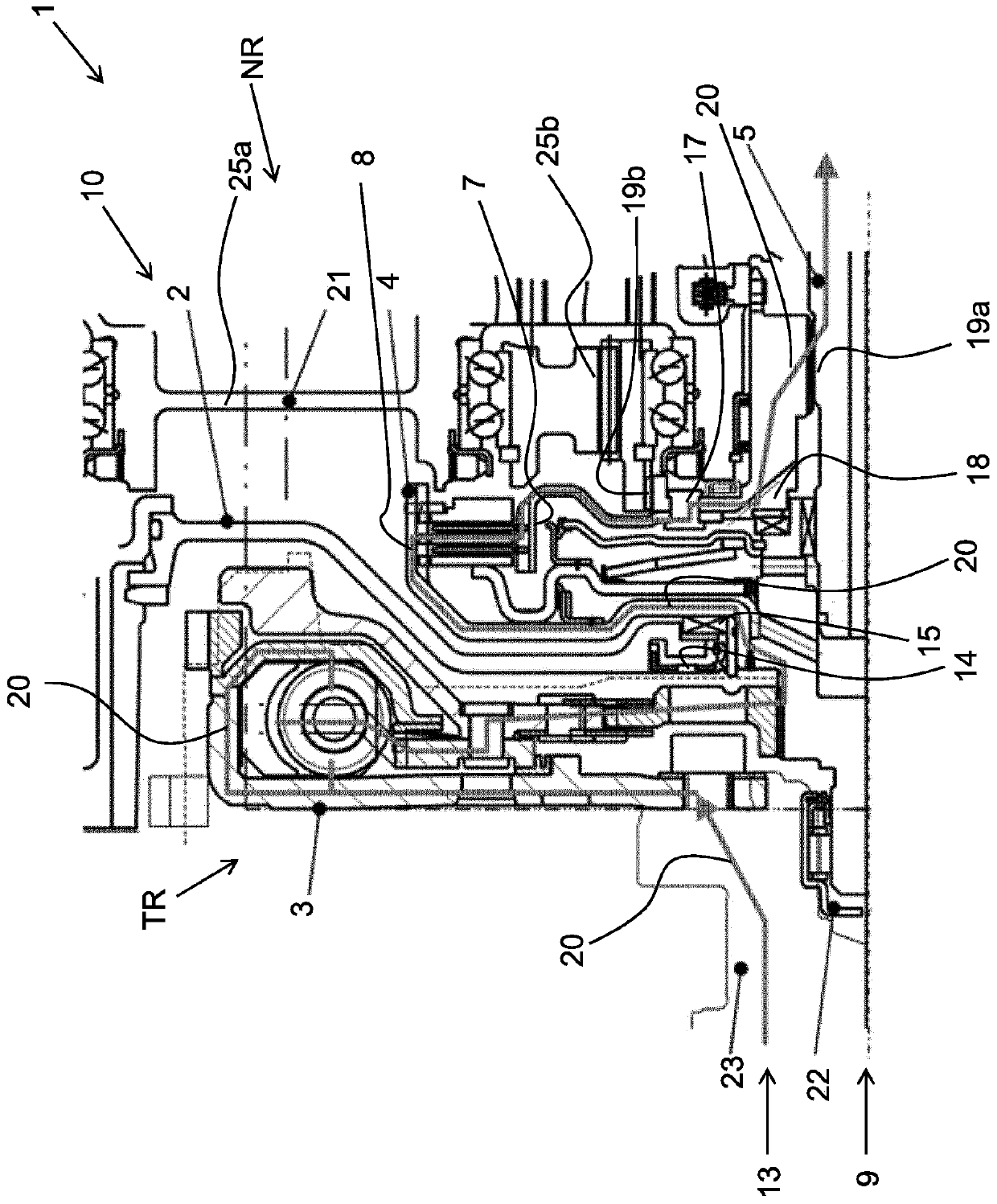

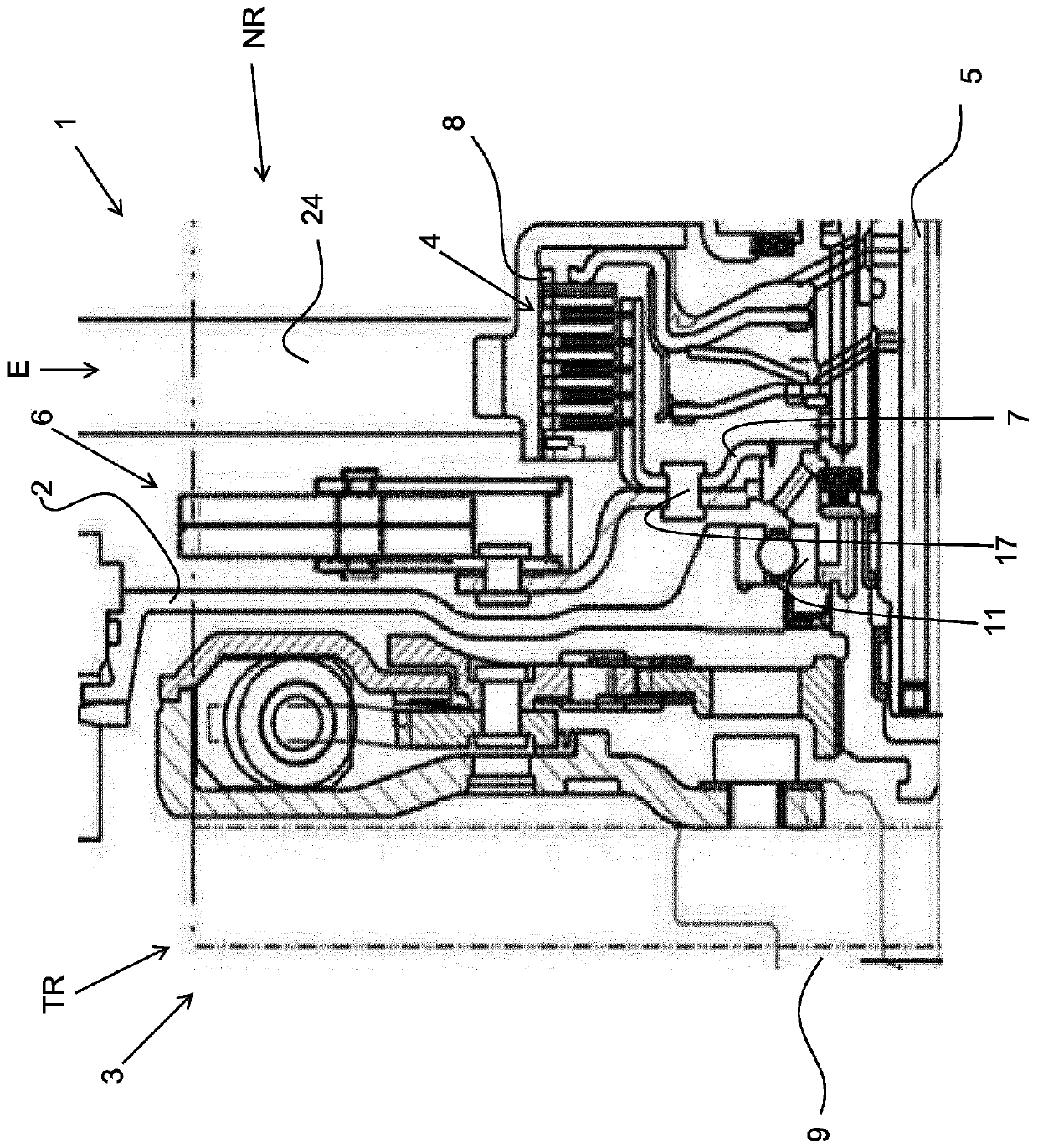

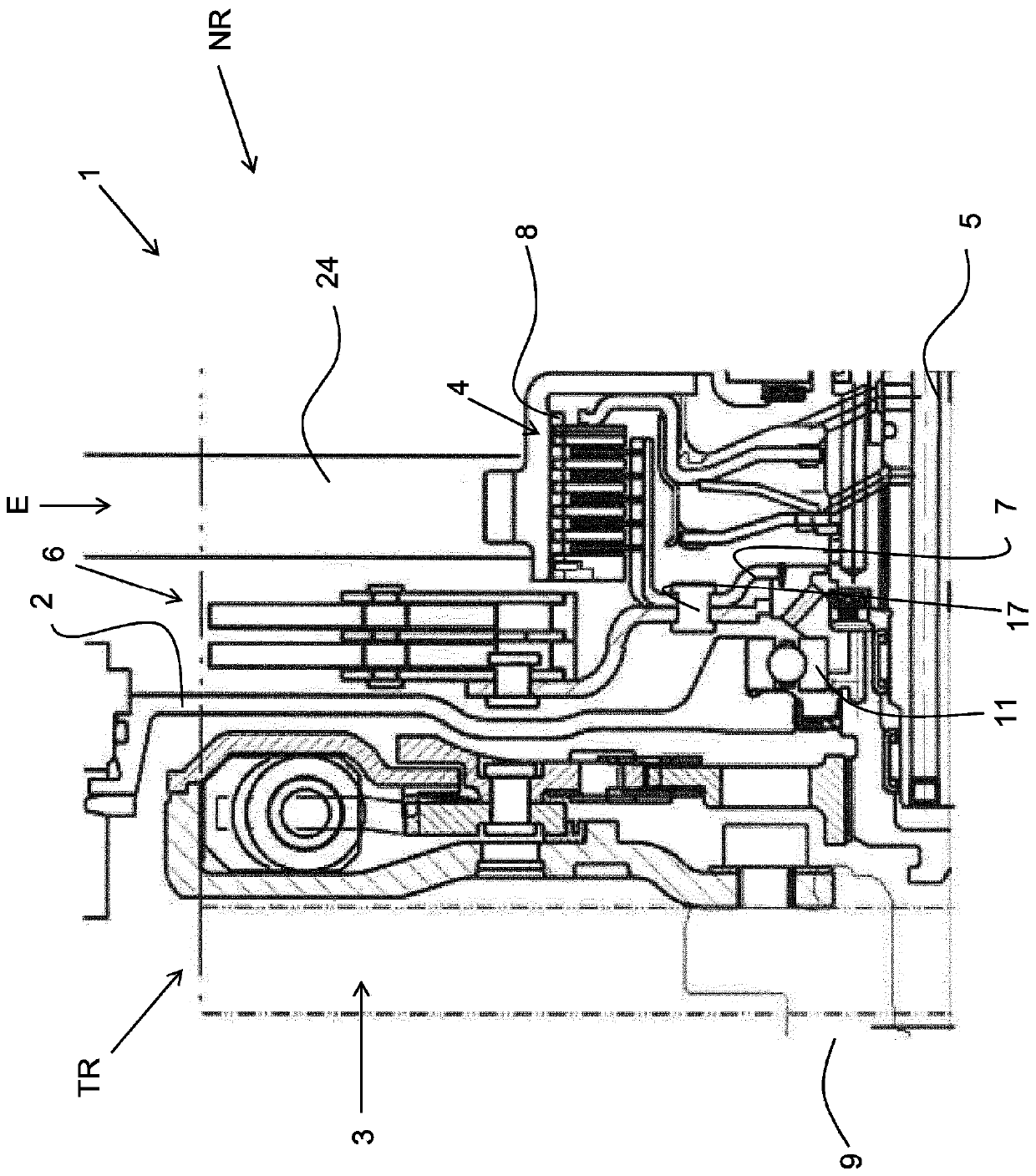

[0037] figure 1 A transmission assembly according to one embodiment of the invention is shown.

[0038] exist figure 1 The transmission assembly 1 is shown in . The transmission assembly 1 has a bearing end cover 2, and the bearing end cover divides the transmission assembly 1 into figure 1 in the dry room TR located on the left and in the figure 1The wet room NR is located on the right. Arranged in the dry chamber TR is a dual-mass flywheel 3 which is connected to the input hub of the separating clutch 4 . The input hub of the separating clutch 4 is in turn connected to the outer friction lining support 8 . The input hub of the separating clutch 4 is supported on the one hand in the crankpin of the crankshaft 13 via a guide bearing 22 and on the other hand via an axial bearing 15 in the form of a needle thrust bearing together with the collar 14 and the radial shaft seal Supported in the bearing cover 2. The separating clutch 4 comprises, in addition to the outer disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com