A low voc environment-friendly alcohol-free printing process

An environmentally friendly and technological technology, applied in the direction of printing, printing devices, etc., can solve the problems of affecting printing quality, clogging and scaling on the surface of rubber rollers, and affecting the smoothness of the surface of rubber rollers, so as to reduce the number of times of washing the rubber rollers with clean water and reduce production. Cost and utilization efficiency reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A low-VOC environmental protection alcohol-free printing process disclosed by the present invention comprises the following process steps:

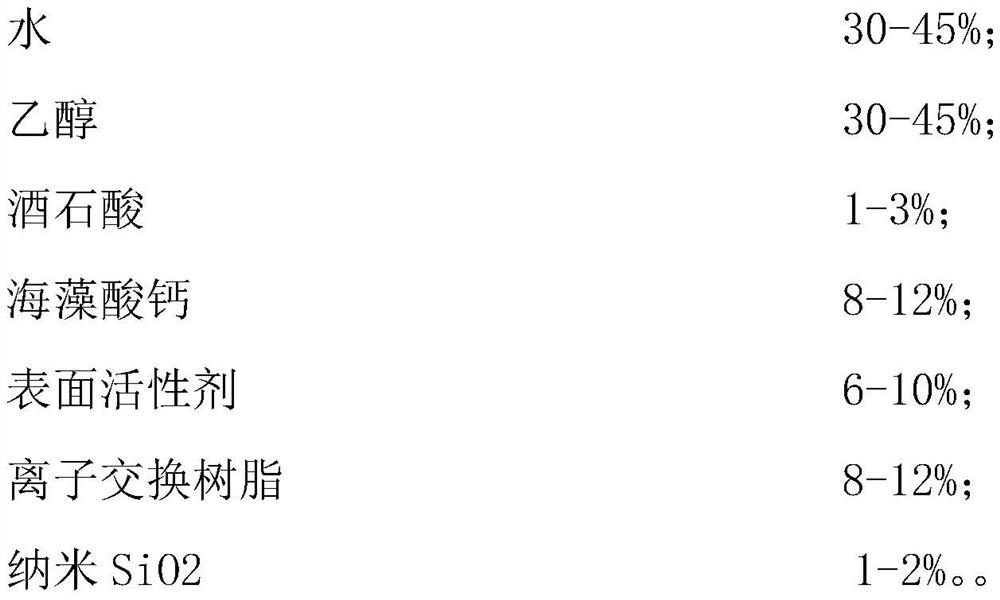

[0072] S1: Prepare the fountain solution, which specifically includes the following steps:

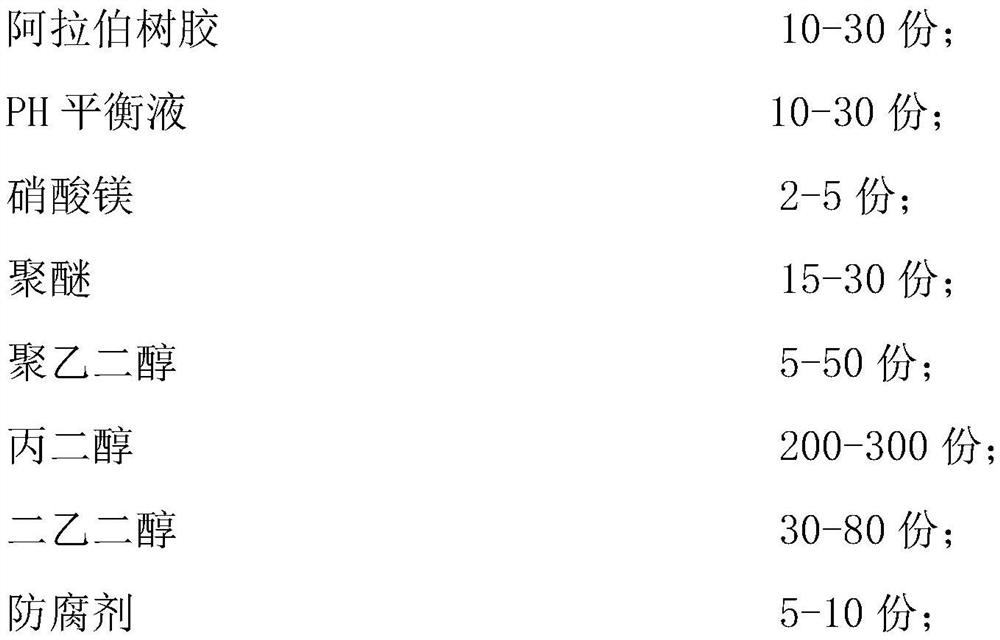

[0073] ①: Take 800 parts by weight of deionized water, 10 parts of pH balance liquid, 2 parts of magnesium nitrate, 4 parts of hardening agent and 5 parts of disodium EDTA into the batching vessel and stir evenly;

[0074] ②: Take 10 parts by weight of gum arabic, and add it into the batching vessel while stirring until the gum arabic is completely dissolved to prepare a colloidal solution;

[0075] ③: Add 5 parts by weight of polyethylene glycol, 200 parts of propylene glycol, 30 parts of diethylene glycol and 5 parts of preservative into the batching vessel and stir evenly;

[0076] ④: Add 5 parts of nonylphenol polyoxyethylene ether, 15 parts of polyether and 5 parts of preservative into the batching vessel and stir evenly to prepare th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com