Desert sand stone-like coating and preparation method thereof

A real stone paint and desert sand technology, applied in the field of rapid prototyping, can solve the problems of fine desert sand, heavy alkalinity and high mud content, and achieve the effect of deep concentration, high saturation, and reduced utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

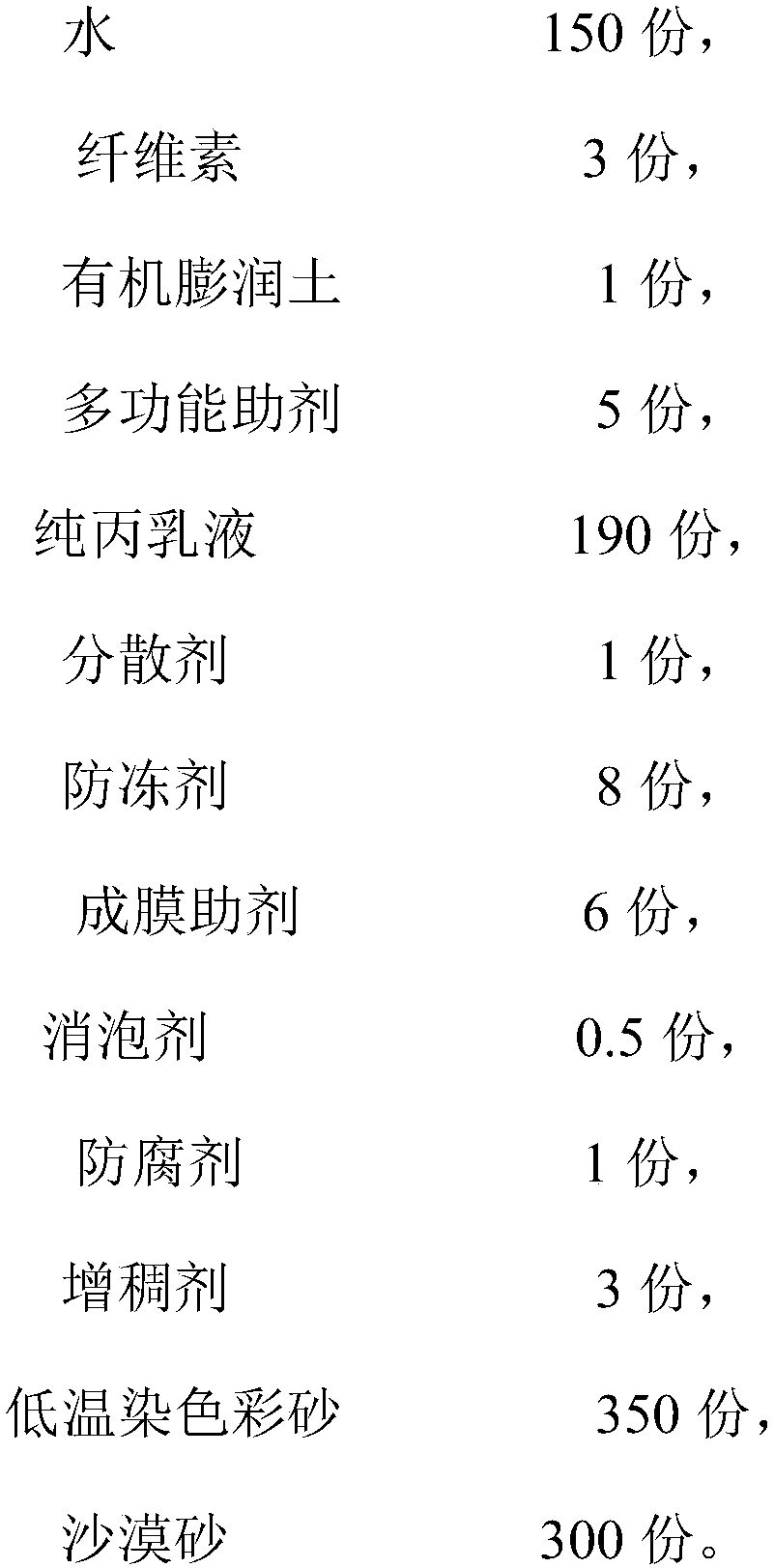

[0026] A kind of desert sand real stone paint of the present invention comprises the following components by mass parts:

[0027]

[0028] A kind of desert sand genuine stone paint of the present invention and preparation method thereof, comprises the following steps:

[0029] (1) Select a suitable container, weigh 3 parts of cellulose and add 70 parts of water under stirring state, stir at room temperature for 20 minutes at a speed of 500-1000 rpm, and stir until the state does not change;

[0030] (2) Weigh 1 part of organic bentonite and add it into 80 parts of water while stirring, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm, until the state does not change;

[0031] (3) Mix the prepared cellulose solution and bentonite solution in proportion, and stir for 10 minutes at a speed of 800-1000 rpm;

[0032] (4) At the speed of 500-1000 rpm, add the multifunctional additives, pure acrylic emulsion, dispersant, antifreeze, film-forming aids, defoam...

Embodiment 2

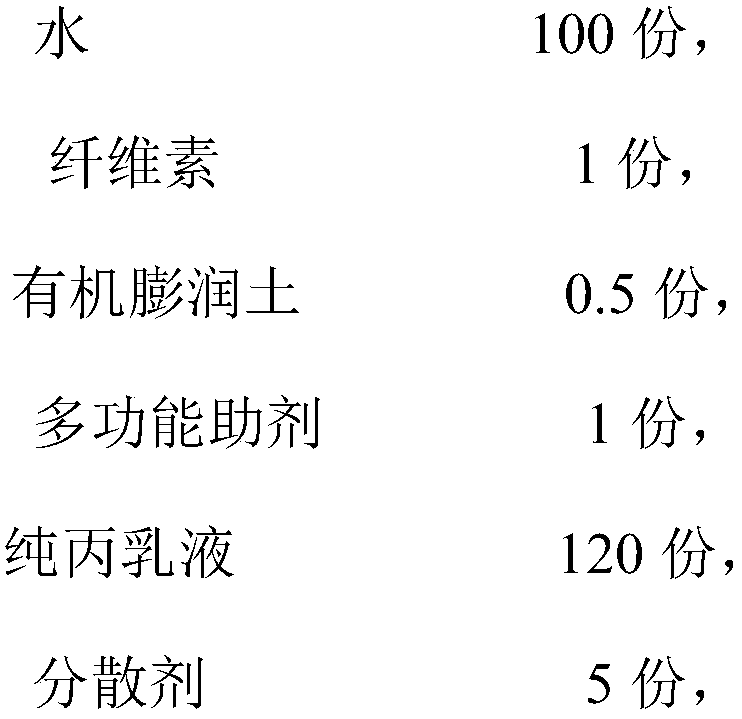

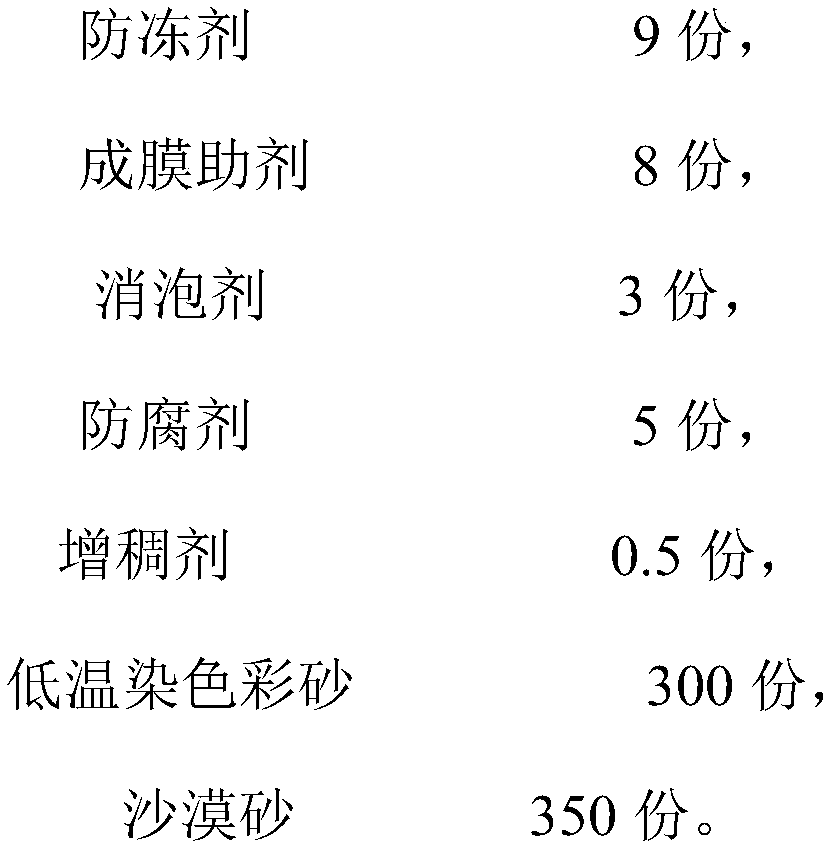

[0035] The difference between embodiment 2 and embodiment 1 is: a kind of desert sand genuine stone paint of the present invention, comprises the following components by mass parts:

[0036]

[0037]

[0038] A kind of desert sand genuine stone paint of the present invention and preparation method thereof, comprises the following steps:

[0039] (1) Select a suitable container, weigh 1 part of cellulose and add it to 50 parts of water under stirring, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm, until the state does not change;

[0040] (2) Weigh 0.5 parts of organobentonite and add it into 50 parts of water under stirring, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm, and stir until the state no longer changes;

[0041] (3) Mix the prepared cellulose solution and bentonite solution in proportion, and stir for 10 minutes at a speed of 800-1000 rpm;

[0042] (4) Under the rotating speed of 500-1000 rpm, add the multifunct...

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is: a kind of desert sand genuine stone paint of the present invention, comprises the following components by mass parts:

[0046]

[0047] A kind of desert sand genuine stone paint of the present invention and preparation method thereof, comprises the following steps:

[0048] (1) Select a suitable container, weigh 2 parts of cellulose and add 70 parts of water under stirring state, stir at room temperature for 20 minutes at a speed of 500-1000 rpm, and stir until the state does not change;

[0049] (2) Weigh 0.7 parts of organobentonite and add it to 70 parts of water under stirring, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm, until the state does not change;

[0050] (3) Mix the prepared cellulose solution and bentonite solution in proportion, and stir for 10 minutes at a speed of 800-1000 rpm;

[0051] (4) Under the rotating speed of 500-1000 rpm, add the multifunctional additives, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap