A formwork trolley for excavating a tunnel with a standard section in a subway section

A formwork trolley and subway technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of increasing construction costs and waste of resources, and achieve the effects of strong device applicability, convenient disassembly and assembly, and improved adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

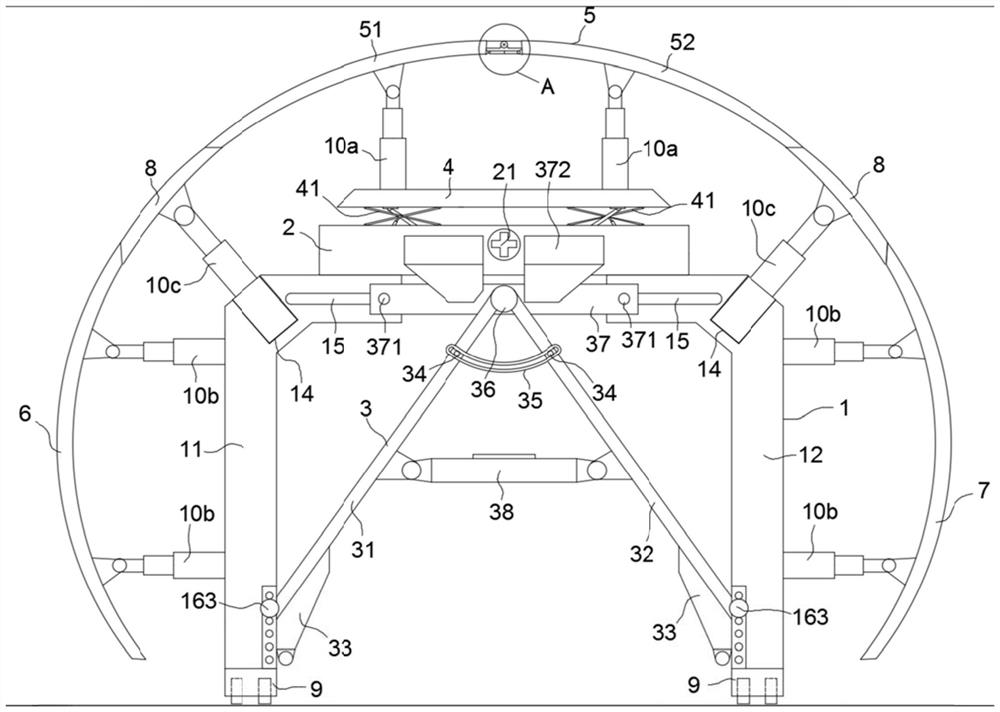

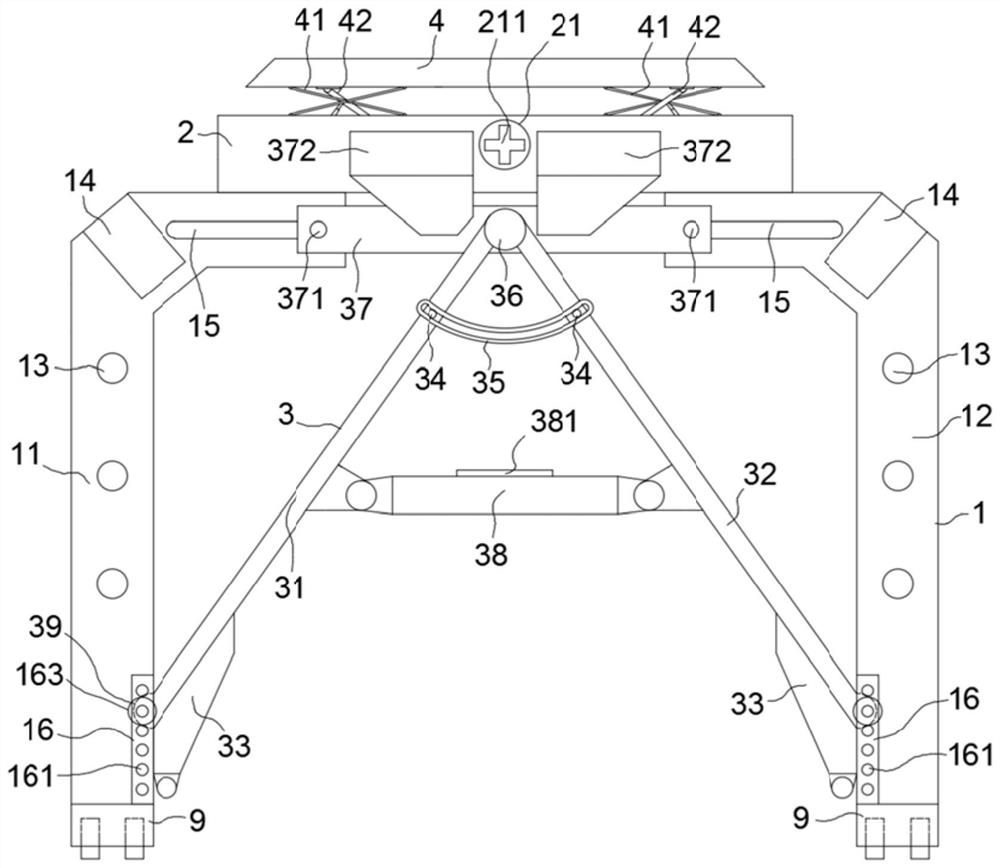

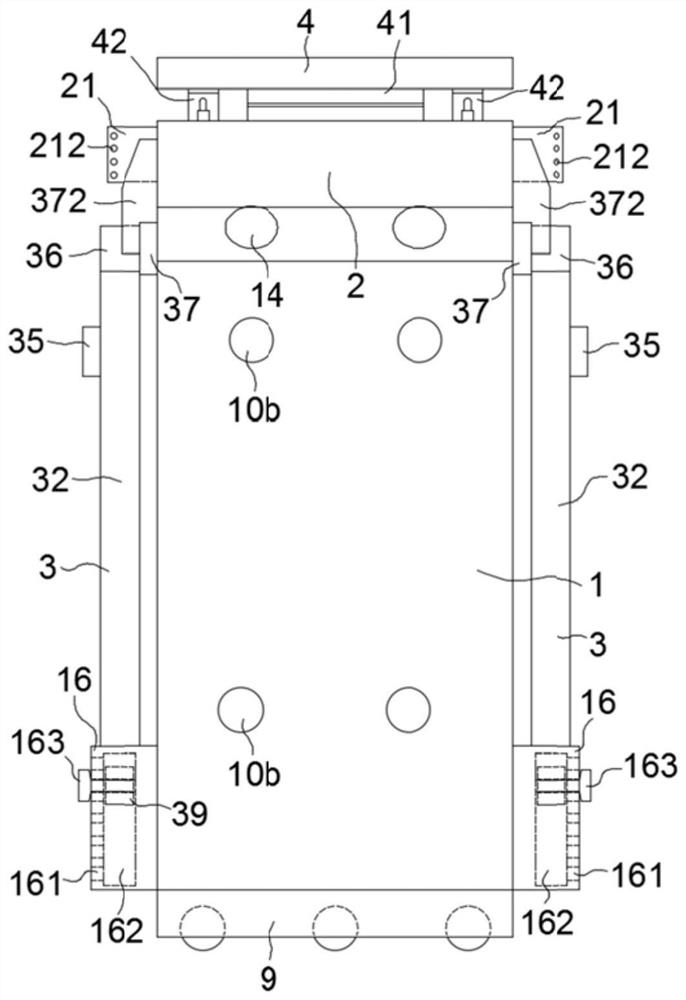

[0040] like figure 1 As shown in the figure, a formwork trolley for excavating a tunnel with a standard section in a subway section mainly includes a variable support 1, a top formwork 5, a left formwork 6, a right formwork 7, and an extension formwork 8;

[0041] like figure 1 and 4 Shown, top formwork 5 is made up of left top formwork 51 and right top formwork 52, and upper part between left top formwork 51, right top formwork 52 is respectively provided with left connection block 54, right connection block 55, left connection block 54, right connection The blocks 55 are rotatably connected by a rotating shaft 53, and an adjustment strut 56 is provided between the left top template 51 and the right top template 52 to be connected with the two. The angle of the top template 5 can be adjusted through the functions of the rotating shaft 53 and the adjustment support rod 56, which is convenient for template amplification with the extension template 8, which is simple and effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com