Edge-computing-oriented equipment calling method and device

An edge computing and equipment technology, applied in the direction of comprehensive factory control, comprehensive factory control, control/regulation system, etc., can solve problems such as poor real-time performance of the call plan, conflict of multi-task equipment call, and difficulty in realizing rapid decision-making on the production site. Achieve high reliability and solve the effect of multitasking equipment retrieval conflicts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0052] The production tasks of the production and processing of shaft parts involve quenching, turning the outer circle, turning the section, drilling the center hole, milling the oil groove, rough grinding the outer circle, fine grinding the outer circle and other processing processes; there are many processing equipment in each process in the production workshop, Including intermediate frequency quenching equipment, high frequency quenching equipment, horizontal lathe, hydraulic rocker drilling machine, vertical milling machine, centerless grinder, cylindrical grinder, abrasive belt grinder and other equipment; the processing equipment retrieval platform adopts B / S structure and provides Windows style user interface.

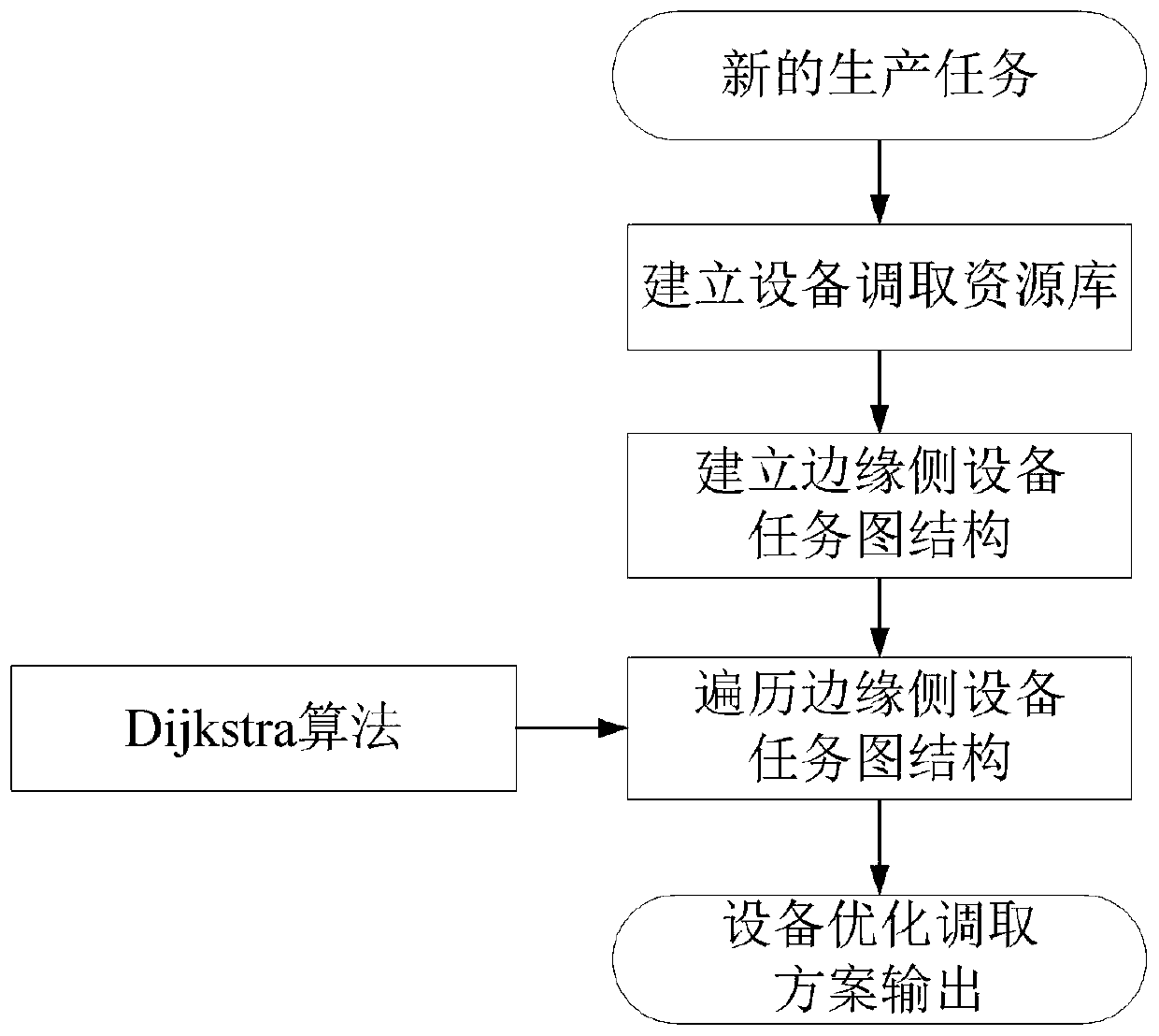

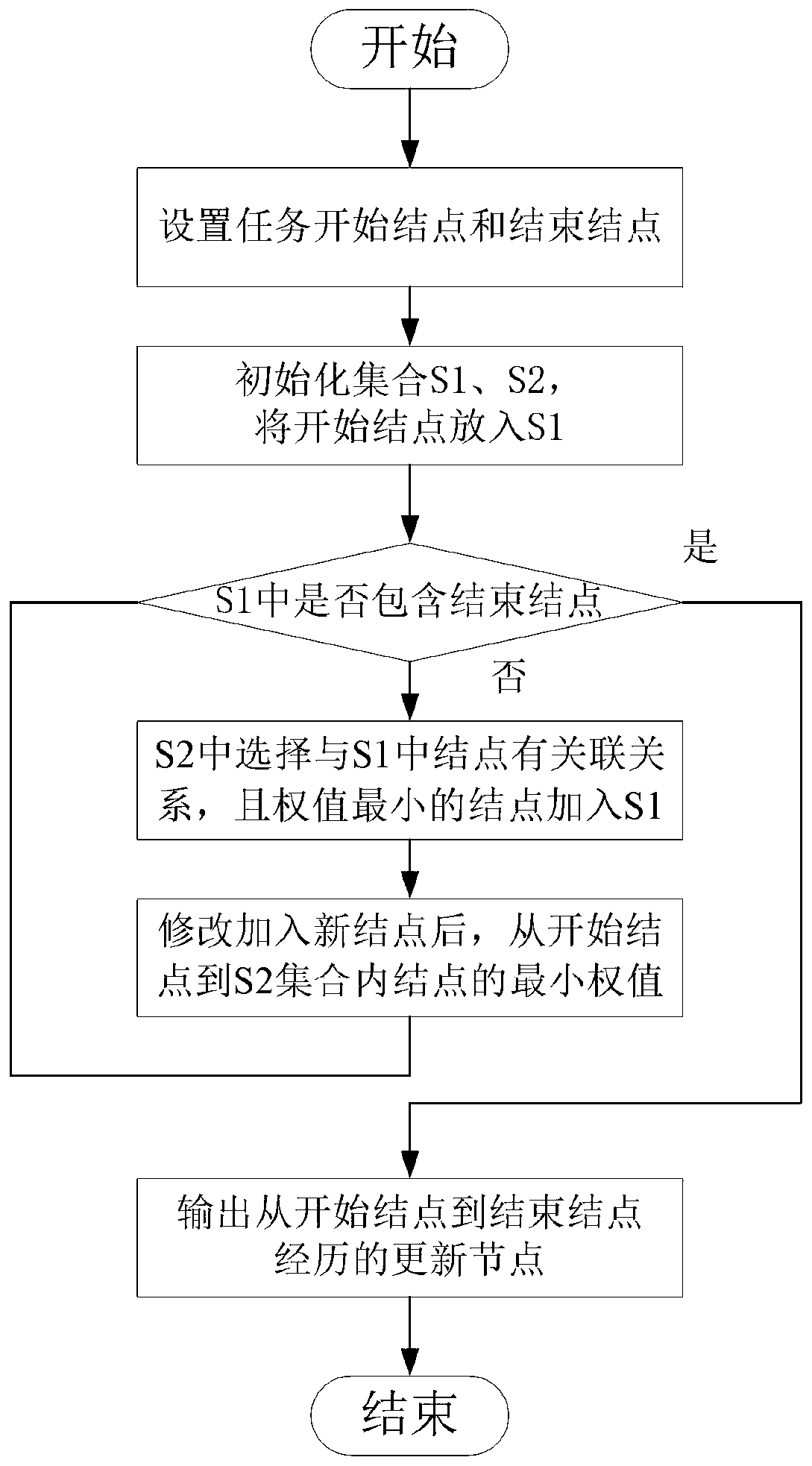

[0053] Such as figure 1 Shown is the general flow diagram of the operation process of the processing equipment retrieval platform for shaft parts in the production task. The main steps of equipment retrieval status calculation and retrieval plan generation are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com