Dimmable LED drive circuit and control method

A technology of LED drive and LED circuit, applied in the direction of light source, electric light source, electrical components, etc., can solve the problems of increasing system loss, flickering light, unable to improve system application power, etc., to improve efficiency and stability, and improve small-angle flickering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to express the technical solutions and advantages of the embodiments of the present invention more clearly, the technical solutions of the present invention will be further described in detail below with reference to the drawings and embodiments.

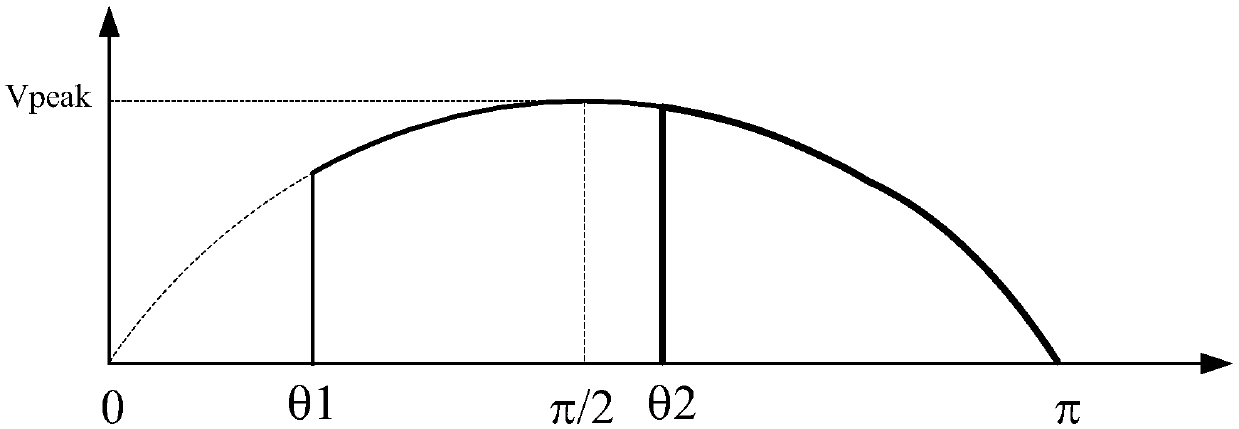

[0045] In the following embodiments of the present invention, the description of the conduction cutting angle of the thyristor dimmer 10 is uniformly used as an angle. image 3 A cycle of the rectified input voltage Vin is shown, where θ1 is the minimum initial conduction cutting wave angle, and the conduction cutting wave may occur at any angle between θ1-π. θ2 is one possible example of the initial turn-on chopping angle of a TRIAC dimmer, and θ1<θ2. π-θ1 and π-θ2 are conduction widths of the thyristor dimmer under angles of θ1 and θ2 respectively. The maximum value Vpeak of the input voltage Vin appears at an angle of π / 2.

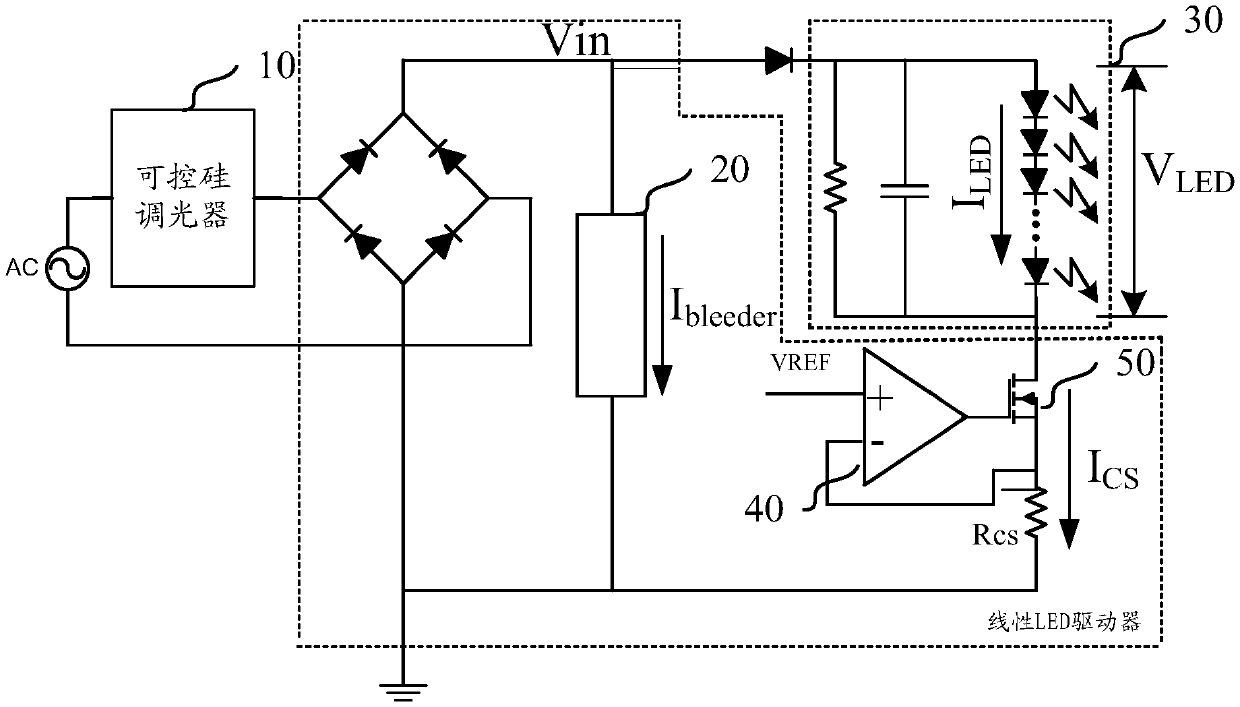

[0046] figure 1 It is a dimmable LED drive circuit in the prior art, which includes: AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com