Zirconia all-ceramic crown and manufacturing method thereof

A manufacturing method and technology of zirconia, applied to dentures, etc., can solve the problems of complex structure, increase the cost and workload of patients' tooth care, and affect the overall aesthetics of patients' teeth, so as to improve the strength, improve the connection strength, and not easy to peel off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

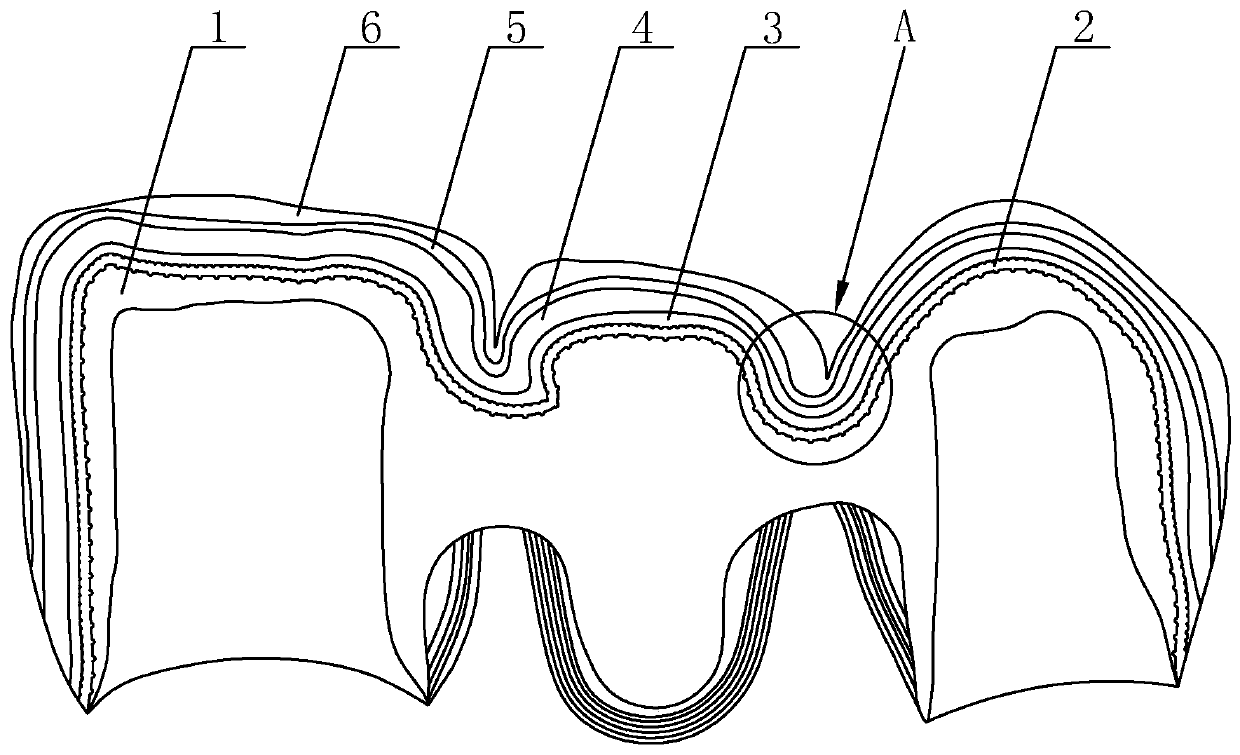

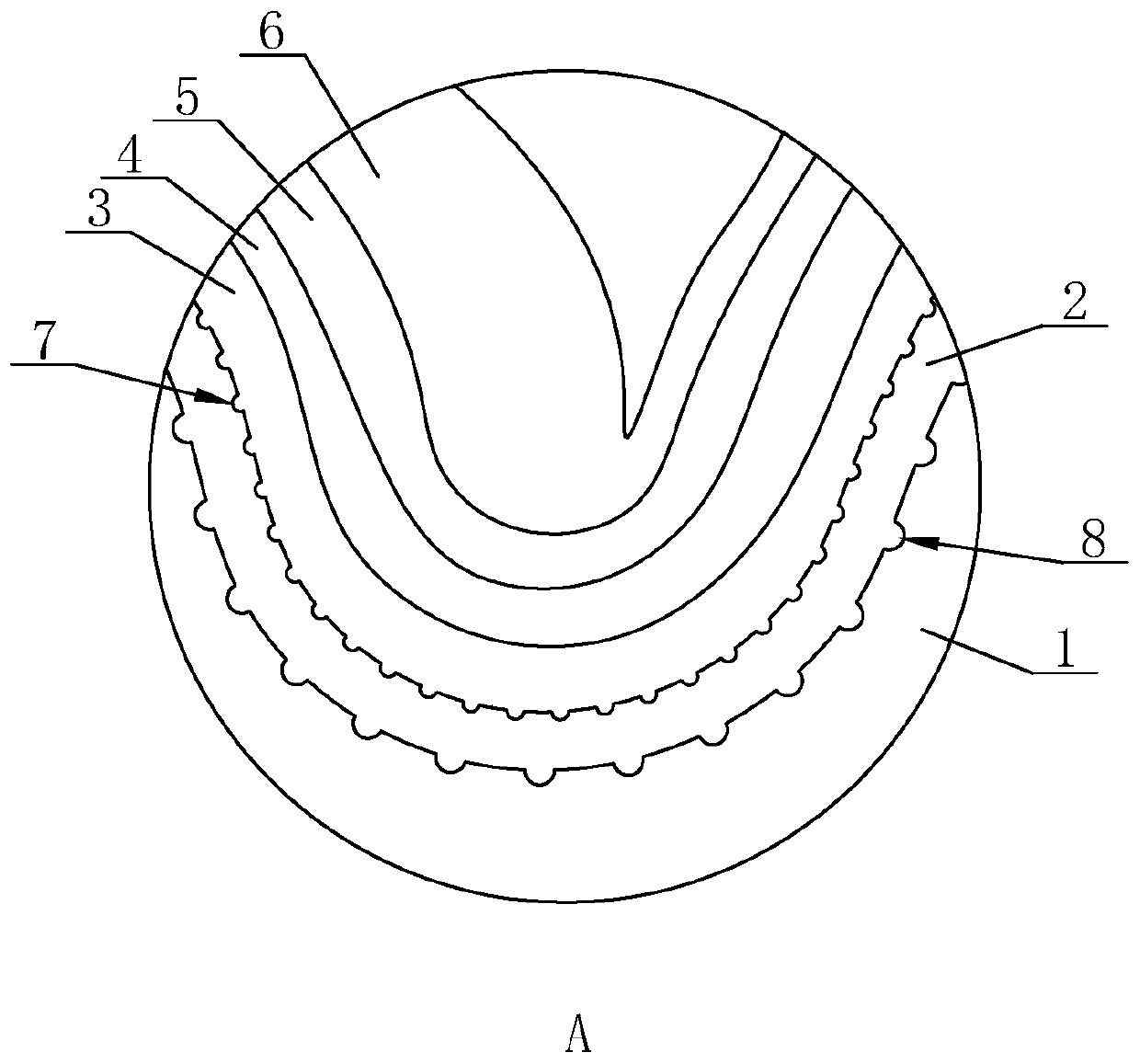

[0045] A zirconia all-ceramic crown, such as figure 1 and figure 2 As shown, including zirconia layer 1, the outer surface of zirconia layer 1 is coated with bonding layer 2, dentin porcelain layer 3, enamel porcelain layer 4, transparent porcelain layer 5 and glaze layer 6, and bonding layer 2 is far away from zirconia The surface of the layer 1 is provided with microgrooves 7, and a plurality of grooves 8 form criss-cross mesh grooves to improve the adhesion between the zirconia layer 1 and the dentin porcelain layer 3, and the outer surface of the zirconia layer 1 is provided with grooves 8, thereby increasing the adhesion between the bonding layer 2 and the zirconia layer 1, and between the dentin porcelain layer 3, the enamel porcelain layer 4, the transparent porcelain layer 5 and the glaze layer 6, due to the similar molecular structure of the materials, the The connection strength between them is sufficient, so that the coated layers are not easy to peel off from the...

Embodiment 2

[0047] A zirconia all-ceramic crown, the difference from Embodiment 1 is that the grooves 8 are formed by the impact of the bonding layer 2 by the particles, the grooves 8 are point-shaped grooves, and a plurality of grooves 8 are scattered outside the bonding layer 2 The surface is used to increase the adhesion between the bonding layer 2 and the zirconia layer 1, so that the bonding layer 2 is not easy to peel off from the zirconia layer 1.

[0048] A method for manufacturing a zirconia all-ceramic crown, comprising the steps of:

[0049] S1. Scan the patient's dental data and enter it into the computer;

[0050] S2. Draw the denture design drawing through CAD technology;

[0051] S3. According to the design drawing, use CAM technology to process the zirconia inner crown and sinter it;

[0052] After the zirconia inner crown is sintered, the outer surface of the zirconia inner crown is sandblasted with a sandblasting machine; The sand particles on the outer surface of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap