Platform loading/unloading carrying system and method for high-speed train express motor train unit

A loading and unloading, high-speed rail technology, applied in the direction of motor vehicles, loading/unloading, transportation and packaging, etc., can solve the problems of long travel distance in container storage warehouses, large number of AGV cars, and ensure the safety of high-speed rail trains, etc., to achieve the efficiency of loading and unloading operations High efficiency, save loading and unloading time, and reduce the number of configurations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

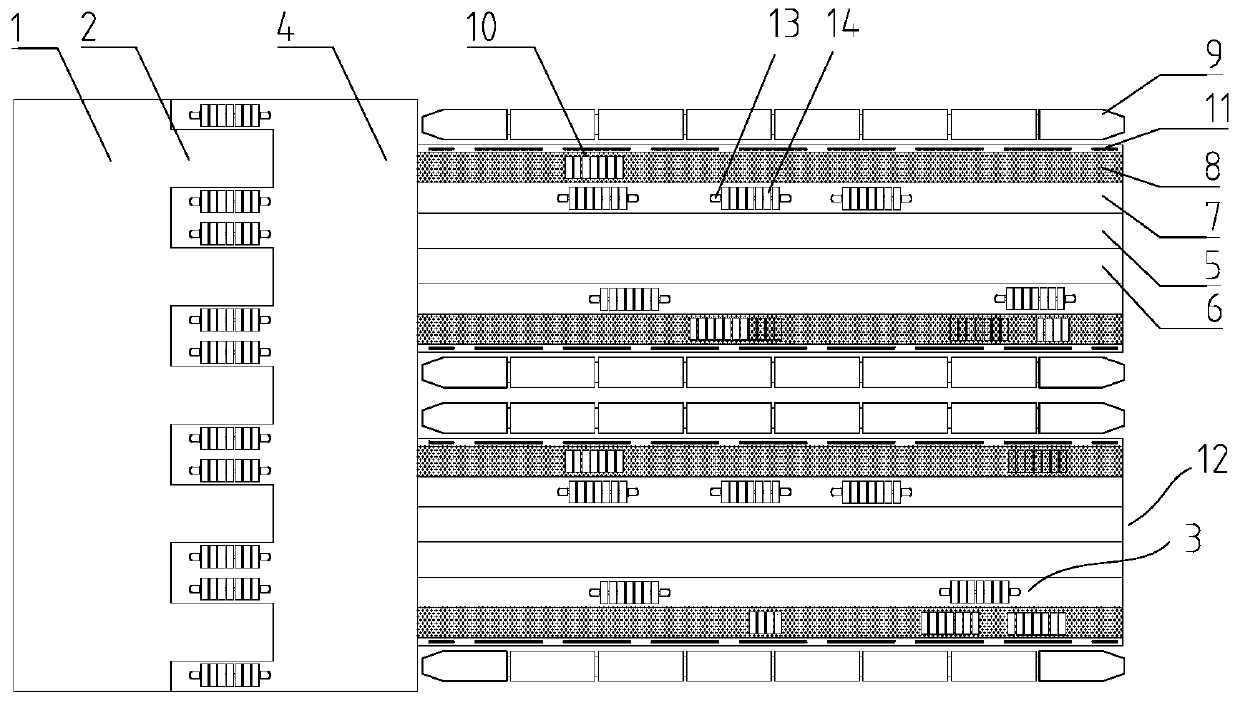

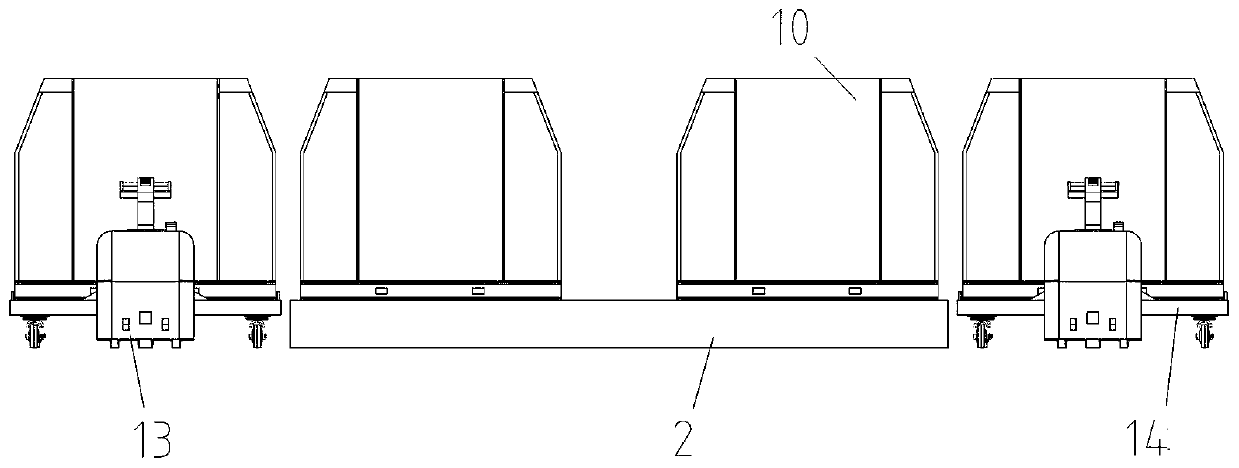

[0030] like figure 1 As shown, the present invention is used for the platform loading and unloading system of the high-speed rail express train group, and it comprises: a plurality of parallel setting platform 12, and described platform 12 is the end-type platform, and the end of described platform 12 is connected with AGV traction trailer dredging successively District 4 and high-speed rail express container transfer center 1; multiple containers 10 are arranged in the high-speed rail express container transfer center 1, and the containers 10 are used to load goods to be transported; A plurality of rectangular tractor-trailer loading and unloading platforms 2 connected to the high-speed rail express container transfer center 1, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com