Preparation method and application of polyphosphazene polymer modified halloysite nanotube composite material with different coating thickness

A technology of halloysite nanotubes and composite materials is applied in the field of preparation of polyphosphazene polymer-modified halloysite nanotube composite materials, which can solve the problems of poor fire resistance, flammability, and reduced mechanical properties, and achieves improved thermodynamics. performance, smoke reduction, mass and energy transfer reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

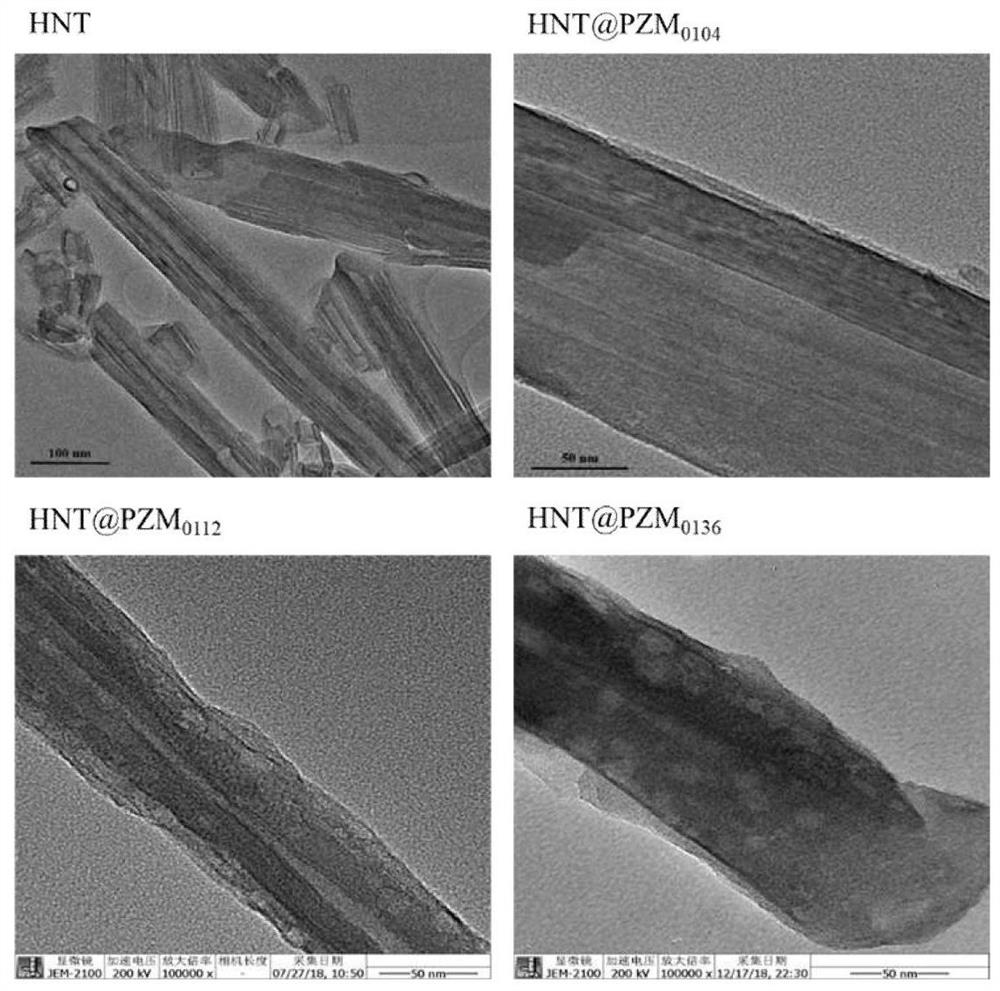

[0032] HNT@PZM 0104 Preparation: Place 0.1g-0.2g halloysite nanotubes in 50mL-100mL analytically pure acetonitrile solvent, perform ultrasonic dispersion for 30min in an ultrasonic machine with an ultrasonic power of 90w, and add 0.03mol-0.06mol Stir the double-terminated amine substance and 2mL-6mL triethylamine; ② Slowly drop into the above solution acetonitrile solution (0.01g / mL-0.03g / mL) dissolved with a certain concentration of hexachlorocyclotriphosphazene, at 40 Stir at -80°C for condensation polymerization for 6-24h; ③Centrifuge and wash the above-mentioned reaction product with absolute ethanol several times, and vacuum-dry it at 40-80°C until constant weight to obtain a light yellow solid. Thickness is polyphosphazene polymer coating thickness at 3-15nm, promptly gets as figure 1 with figure 2 HNT@PZM shown 0104 .

Embodiment 2

[0034] HNT@PZM 0112 Preparation: Place 0.1g-0.2g halloysite nanotubes in 50mL-100mL analytically pure acetonitrile solvent, perform ultrasonic dispersion for 30min in an ultrasonic machine with an ultrasonic power of 90w, and add 0.06mol-0.12 mol double-terminal amine substance and 2mL-6mL triethylamine are stirred; ② Slowly drop into the above solution a solution of acetonitrile (0.02g / mL-0.06g / mL) with a certain concentration of hexachlorocyclotriphosphazene dissolved therein. Stir at 40-80°C for condensation polymerization for 6-24h; ③Centrifuge and wash the above-mentioned reaction product with absolute ethanol several times, and vacuum-dry it at 40-80°C until constant weight to obtain a light yellow solid, in which the shell Layer thickness is polyphosphazene polymer coating thickness at 8-25nm, promptly gets as figure 1 HNT@PZM shown 0112 .

Embodiment 3

[0036] HNT@PZM 0136 Preparation: 0.1g halloysite nanotubes were placed in analytically pure acetonitrile, ultrasonically dispersed in an ultrasonic machine with an ultrasonic power of 90w for 30min, and 0.12mol-0.24mol double-ended amine substances and 2mL- Stir with 6mL triethylamine; ②Slowly drop acetonitrile solution (0.06g / mL-0.12g / mL) dissolved with a certain concentration of hexachlorocyclotriphosphazene into the above solution, and stir at 40-80°C for condensation Polymerization reaction for 6-24 hours; ③Centrifugal wash the above reaction product with absolute ethanol for several times, and vacuum-dry it at 40-80°C until constant weight to obtain a light yellow solid, in which the thickness of the shell is the thickness of the polyphosphazene polymer The coating thickness is 8-30nm, that is, as figure 1 HNT@PZM shown 0136 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com