Heat conduction composite material with aluminum-like linear expansion coefficient and preparation method thereof

A technology of linear expansion coefficient and heat-conducting composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as influence, stress cracking, and large difference in thermal expansion coefficients, and achieve broad application prospects, good mechanical strength, The effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A thermally conductive composite material with a linear expansion coefficient of aluminum. The components and their contents in the raw material are: 32 parts of PA6, 1 part of ethylene-propylene copolymer, 2 parts of branching agent, and 36 parts of thermally conductive filler. , 24 parts of glass fiber; among them, the melting point of PA6 is 218 ° C, the melting point of polypropylene is 141 ° C; the molar content of ethylene in the ethylene-propylene copolymer (W1) is 11%, and the branching agent is E60- P; thermally conductive filler is spherical Al modified by silane coupling agent 2 O 3 , D50 diameter (D1) is 3 μ m, D10 (D2) diameter 15 μ m, the mass content (W2) of silane coupling agent is 1%; 1:3;

[0026] The preparation method is: after mixing the components except glass fiber according to the formula ratio to obtain the mixture, feed the mixture into the twin-screw extruder from the main feeding port, and feed the glass fiber into the twin-screw extruder f...

Embodiment 2~8

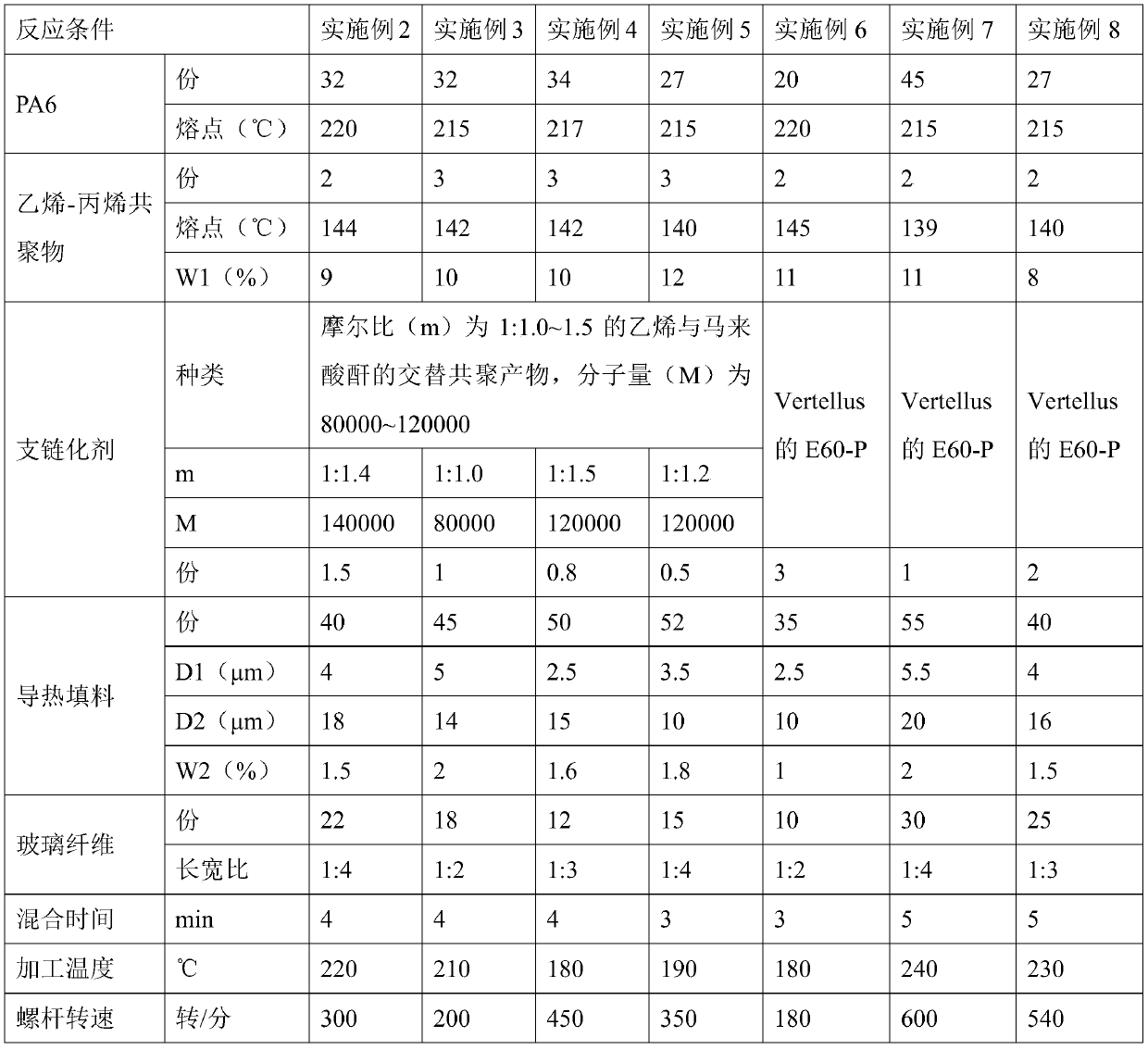

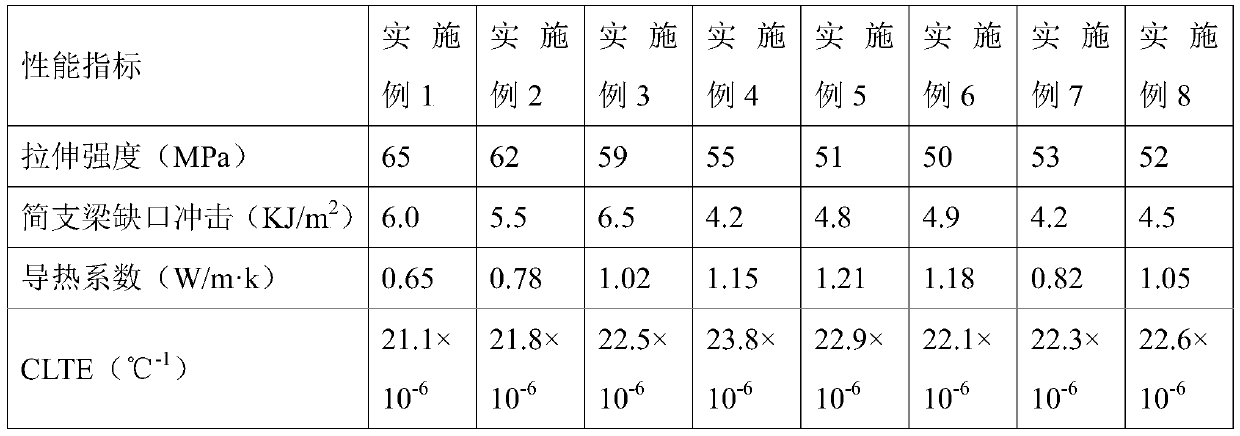

[0029]A heat-conducting composite material with a linear expansion coefficient of aluminum, the preparation method of Examples 2-8 is basically the same as that of Example 1, the difference lies in the process parameters, see Table 1 for details; the performance indicators of the corresponding products in Examples 2-8 The test method is the same as in Example 1, and the test results are shown in Table 2.

[0030] Table 1

[0031]

[0032] Table 2

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com