Composite phase change material for heating non-burning tobacco heat source and preparation method thereof

A composite phase-change material and heat-not-burn technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of heat-not-burn tobacco heat sources that cannot be used, and phase change temperatures that cannot meet heat-not-burn tobacco heat sources, etc. problem, to achieve the effect of increasing thermal conductivity, reducing preheating time, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention proposes a method for preparing a composite phase-change material used as a heat-not-burn tobacco heat source, the preparation method comprising the following steps:

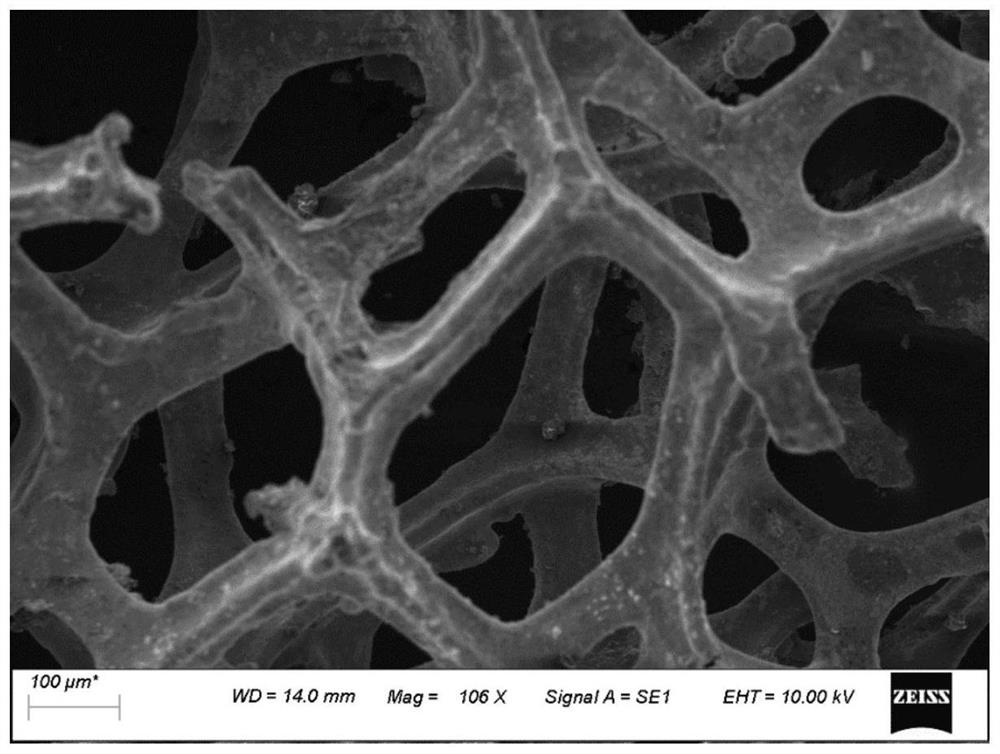

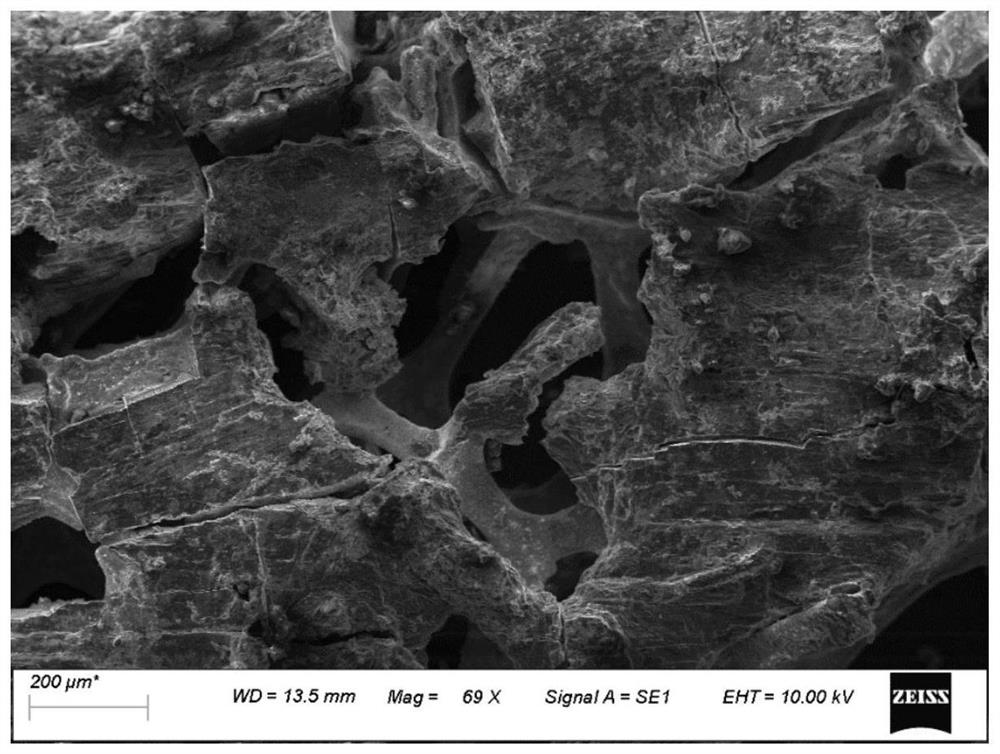

[0028] Fill the metal foam with inorganic salt as phase change material to obtain composite phase change material matrix. The phase change temperature of inorganic salt is 200°C-450°C;

[0029] A protective layer is coated on the surface of the matrix of the composite phase-change material to obtain the composite phase-change material used for heating non-burning tobacco heat sources.

[0030] Here, inorganic salt is a high-temperature phase change material. When changing from liquid to solid state, the temperature of the material itself remains almost unchanged before the phase change is completed, forming a wide temperature platform and releasing a large amount of latent heat at the same time. And the phase transition temperature of the selected inorganic salt is 200°C-450°C, which...

Embodiment 1

[0048] First, put the mixed inorganic salts of sodium carbonate, lithium carbonate, and potassium carbonate with a mass ratio of 1:1:1 into a pulverizer, and pulverize at a speed of 15000r / min for 30s to obtain a uniformly mixed ternary carbonate. Then, under vacuum conditions, the ternary carbonate is heated to a molten state, so that the molten ternary carbonate is impregnated into the pores of the foamed copper to obtain a composite phase change material matrix, where the ternary carbonate is filled The efficiency is 85%. Finally, a metal copper foil layer is coated on the surface of the matrix of the composite phase change material to obtain the composite phase change material, and the phase change temperature of the composite phase change material is 380°C.

Embodiment 2

[0050] First, the mixed inorganic salt of sodium nitrate and potassium nitrate with a mass ratio of 3:1 was put into a pulverizer, and pulverized at a speed of 15000r / min for 30s to obtain a uniformly mixed binary nitrate. Then, under vacuum conditions, the binary nitrate is heated to a molten state, so that the molten binary nitrate is impregnated into the pores of the foamed copper to obtain a composite phase change material matrix, where the filling efficiency of the ternary carbonate is 86%. Finally, a metal copper foil layer is coated on the surface of the matrix of the composite phase change material to obtain the composite phase change material, and the phase change temperature of the composite phase change material is 220°C.

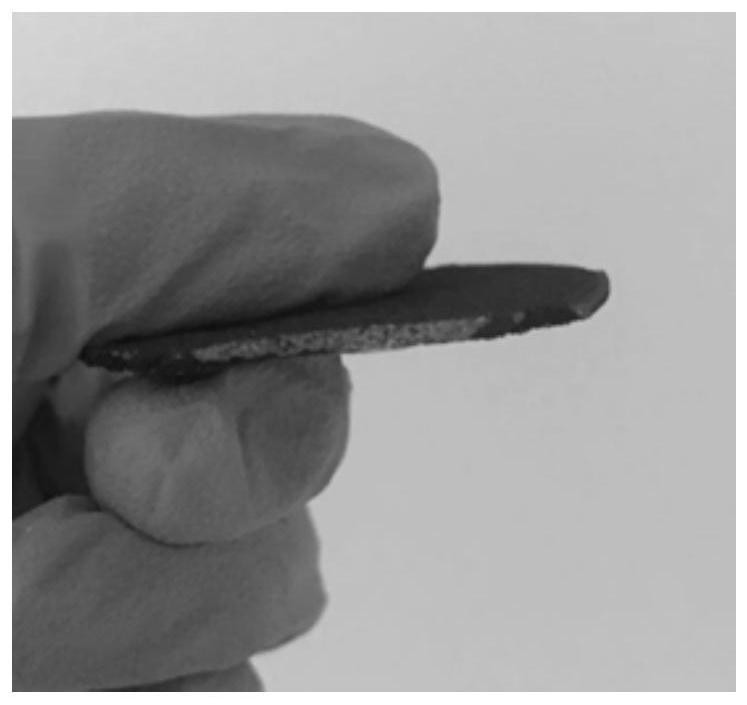

[0051] The embodiment is prepared to obtain a composite phase change material partition, and its cross-sectional view is taken, such as figure 1 shown by figure 1 It can be seen that the ternary carbonate is evenly distributed in the voids of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com