Niobium titanium microalloyed HRB500E screw-thread steel and preparation method thereof

A technology of micro-alloying and rebar, which is applied in the direction of metal rolling, etc., can solve the problems of high price of vanadium alloy, difficulty in controlling the cost of production enterprises and users, etc., so as to reduce the use of V, realize the effect of precipitation strengthening, and reduce the cost of alloy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

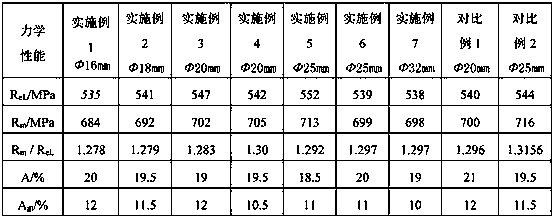

Examples

Embodiment Construction

[0034] In order to better explain the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples. The following examples are only illustrative technical solutions of the present invention, and do not limit the present invention in any form .

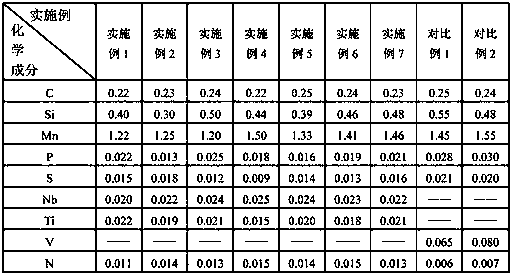

[0035] Following table 1 is the mass percentage list of chemical composition contained in each embodiment of the present invention and comparative example rebar;

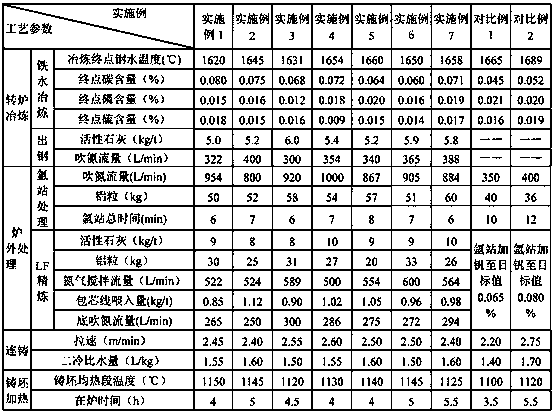

[0036] Table 2 below is the value list of each process parameter in each embodiment of the present invention and the preparation method of comparative example rebar;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com