GH4780 alloy billet and forged piece and preparing method thereof

A technology of alloy and billet, which is applied in the field of GH4780 alloy billet and forging and its preparation, can solve the problems restricting the use of GH4780 alloy, and achieve the effect of uniform grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of GH4780 alloy billet provided by the present invention comprises the following steps:

[0036] At 900-1160°C, the GH4780 alloy ingot is elongated and upset for at least two fires, with a deformation amount of 10%-50%, to break the columnar crystals, and complete the recrystallization process to obtain the GH4780 alloy billet.

[0037] The application carries out elongation and upsetting at a specific temperature, and obtains a GH4780 alloy billet after heat treatment. The grain structure of the obtained GH4780 alloy billet is uniform. After heat treatment, the average grain size reaches ASTM4 grade or finer. Among them, the elongation and upsetting temperature of multiple fires can be selected from 900 to 1160°C, such as 900°C, 950°C, 1000°C, 1050°C, 1100°C, 1150°C, and 1160°C. The elongation and upsetting of multiple fires are conducive to the completion of the crushing and recrystallization process of columnar crystals.

[0038] Prefera...

Embodiment 1

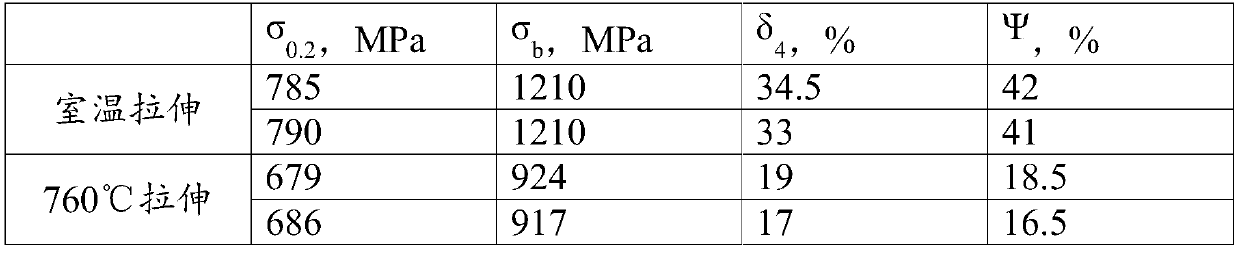

[0069] The GH4780 alloy ingot was smelted by the GH4780 double-combination process. After elongation and upsetting at 1150 ° C and subsequent multiple fire treatments, the deformation amount was 10% to 50%. The mechanical properties of the obtained billet are shown in Table 1.

[0070] Table 1 mechanical performance test results

[0071]

Embodiment 2

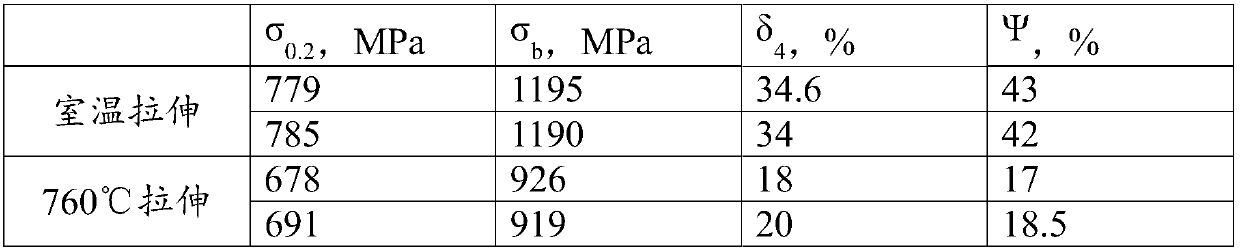

[0073] The GH4780 alloy ingot was smelted by the GH4780 double process. After elongation and upsetting at 1120°C and subsequent multiple fire treatments, the deformation amount was 10% to 50%. The mechanical properties of the obtained billet are shown in Table 2.

[0074] Table 2 mechanical properties test results

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com