Graphite-like carbon nitride/graphene/graphene oxide composite aerogel and preparation method thereof

A composite technology of graphite phase carbon nitride and graphene, which is applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., can solve the problems of insufficient dye adsorption capacity and low photocatalytic efficiency, and achieve photodegradation Efficiency improvement, solution to low photocatalytic efficiency, and improvement of degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

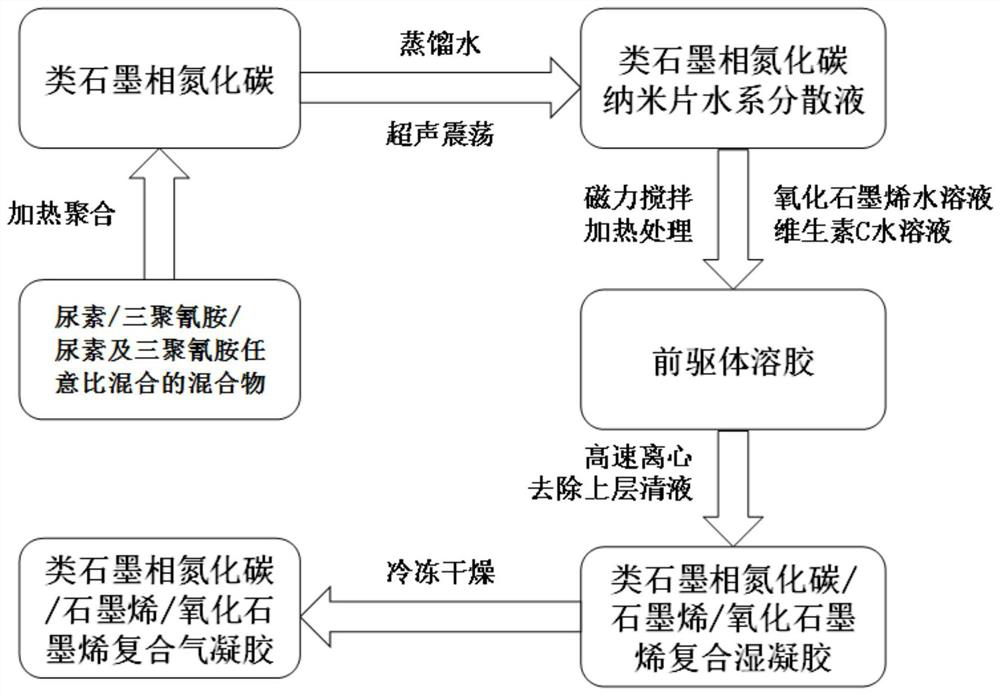

[0043] The invention provides a preparation method of graphite-like carbon nitride / graphene / graphene oxide composite airgel, such as figure 1 As shown, it specifically includes the following steps:

[0044] Step 1: Grind urea or melamine or a mixture of urea and melamine in any ratio into powder and place it in an alumina crucible, place the crucible in a muffle furnace, and raise the temperature from room temperature to 530-570 ° C, keep at 530-570 ° C for 3-4 hours, you can get graphite-like phase carbon nitride; alumina crucible can be 50mL or 100mL volume.

[0045] Step 2, mixing the graphite-like phase carbon nitride obtained in step 1 with distilled water, and ultrasonically vibrating the mixed liquid for 4-6 hours to obtain a graphite-like phase carbon nitride nanosheet aqueous dispersion;

[0046] In step 2, the mass ratio of graphite-like carbon nitride to distilled water is 1:2000.

[0047] Step 3, mix the graphite-like phase carbon nitride nanosheet aqueous disper...

Embodiment 1

[0057] Preparation of graphite-like phase carbon nitride / graphene / graphene oxide composite airgel with graphite-like phase carbon nitride nanosheet aqueous dispersion, graphene oxide aqueous solution, and vitamin C aqueous solution at a volume ratio of 12:10:3.

[0058] First, grind 30 g of urea into powder and place it in a 50 mL alumina crucible, place the crucible in a muffle furnace, raise the temperature from room temperature to 550 °C at a heating rate of 10 °C / min, and keep at 550 °C for 4 hours, that is Carbon nitride in a graphitic phase can be obtained.

[0059] Secondly, the graphite-like carbon nitride and distilled water were mixed at a mass ratio of 1:2000, and the mixed liquid was ultrasonically oscillated for 4 hours to obtain a 0.5 mg / mL aqueous dispersion of graphite-like carbon nitride nanosheets.

[0060] Third, mix 0.5 mg / mL graphitic-phase carbon nitride nanosheet aqueous dispersion with 6 mg / mL graphene oxide aqueous solution and 100 mg / mL vitamin C aque...

Embodiment 2

[0065] Preparation of graphite-like phase carbon nitride / graphene / graphene oxide composite airgel with graphite-like phase carbon nitride nanosheet aqueous dispersion, graphene oxide aqueous solution, and vitamin C aqueous solution at a volume ratio of 6:10:3.

[0066] First, grind 30g of urea into powder and place it in a 50mL alumina crucible, place the crucible in a muffle furnace, raise the temperature from room temperature to 530°C at a heating rate of 8°C / min, and keep it at 530°C for 4h , to obtain graphite-like carbon nitride.

[0067] Secondly, the graphite-like carbon nitride and distilled water were mixed at a mass ratio of 1:2000, and the mixed liquid was ultrasonically oscillated for 6 hours to obtain a 0.5 mg / mL aqueous dispersion of graphite-like carbon nitride nanosheets.

[0068] Third, mix 0.5 mg / mL graphitic phase carbon nitride nanosheet aqueous dispersion with 6 mg / mL graphene oxide aqueous solution and 100 mg / mL vitamin C aqueous solution at a volume rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com