Glass fiber mat-nano tio2 coating structure and its preparation method and application

A kind of glass fiber mat and nanotechnology, which is applied in the direction of chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of weak bonding, low loading capacity, low photocatalytic efficiency, etc., and achieve excellent Reusability, the effect of solving the low photocatalytic efficiency of TiO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In the method for preparing linear titanyl polymer of the present invention, the structure of the preferred titanate is Ti(OR 1 ) 4 , where R 1 are independently selected from -C 2 h 5 ,-C 3 h 7 ,-C 4 h 9 , -C 5 h 11 . Tetrabutyl titanate is preferred.

[0050] In the method for preparing linear titanyl polymer of the present invention, preferably, the chelating agent is one or both of acetylacetone and ethyl acetoacetate.

[0051] In the method for preparing linear titanyl polymer of the present invention, preferably, the molar ratio of the titanate, chelating agent and water is 1:(0.5-1.4):(0.8-1.3).

[0052] In the method for preparing a linear titanyl polymer of the present invention, preferably in the mixed solution of water and alcohol, the alcohol is one or more of monoalcohols with 2 to 5 carbon atoms, preferably the The molar ratio of water and alcohol in the mixed solution of water and alcohol is 1:(3~20).

Embodiment 1

[0069] Embodiment 1: the preparation of linear titanium oxide polymer

[0070] 1) Add 1 mol of tetraisobutyl titanate into the reaction vessel, adjust the temperature to 50°C, add 0.8mol of acetylacetone, heat and stir at 50°C for 1 hour;

[0071] 2) Adjust the temperature to 80° C., drop in a mixed solution of 0.8 mol of water and 2.5 mol of isobutanol, continue heating and stirring at 80° C. for 2 hours after dropping, and remove the solvent under reduced pressure after dropping the temperature to obtain a yellow titanyl polymer.

[0072] The softening point measured by the ring and ball method is 92° C., and the number average molecular weight Mn=2750 is measured by the vapor pressure osmosis method.

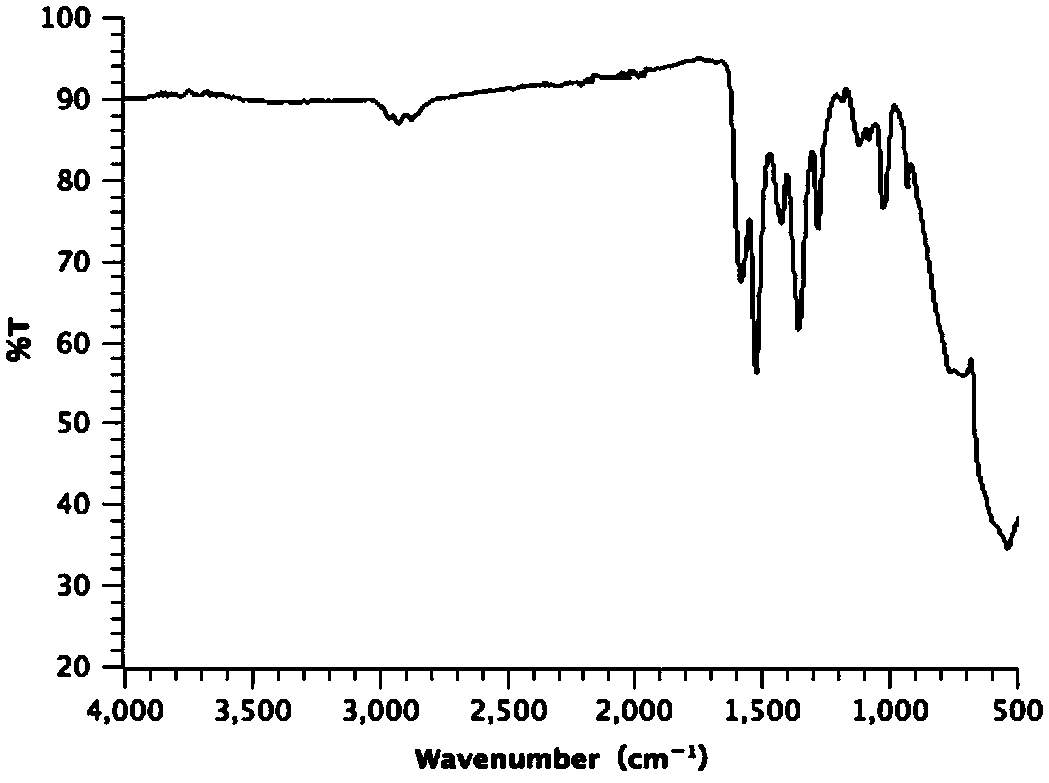

[0073] Grind 1-2 mg of the obtained yellow titanyl oxide polymer and 200 mg of pure KBr evenly, place them in a mold, and press them into transparent flakes on a tablet machine for IR spectrum characterization, see Picture 1-1 ;exist Picture 1-1 Medium, 2959cm -1 、2922cm ...

Embodiment 2

[0075] Embodiment 2: the preparation of linear titanium oxide polymer

[0076] 1) Add 1 mol of tetrabutyl titanate into the reaction vessel, add 0.5 mol of acetylacetone, and heat and stir at 90° C. for 1.5 h;

[0077] 2) Adjust the temperature to 70° C., drop in a mixture of 1.2 mol of water and 6 mol of n-butanol, stir at 100° C. for 2.5 hours after dropping, and remove the solvent under reduced pressure after cooling down to obtain the titanium oxide polymer.

[0078] The softening point measured by the ring and ball method is 98° C., and the number average molecular weight Mn=2930 is measured by the vapor pressure osmosis method.

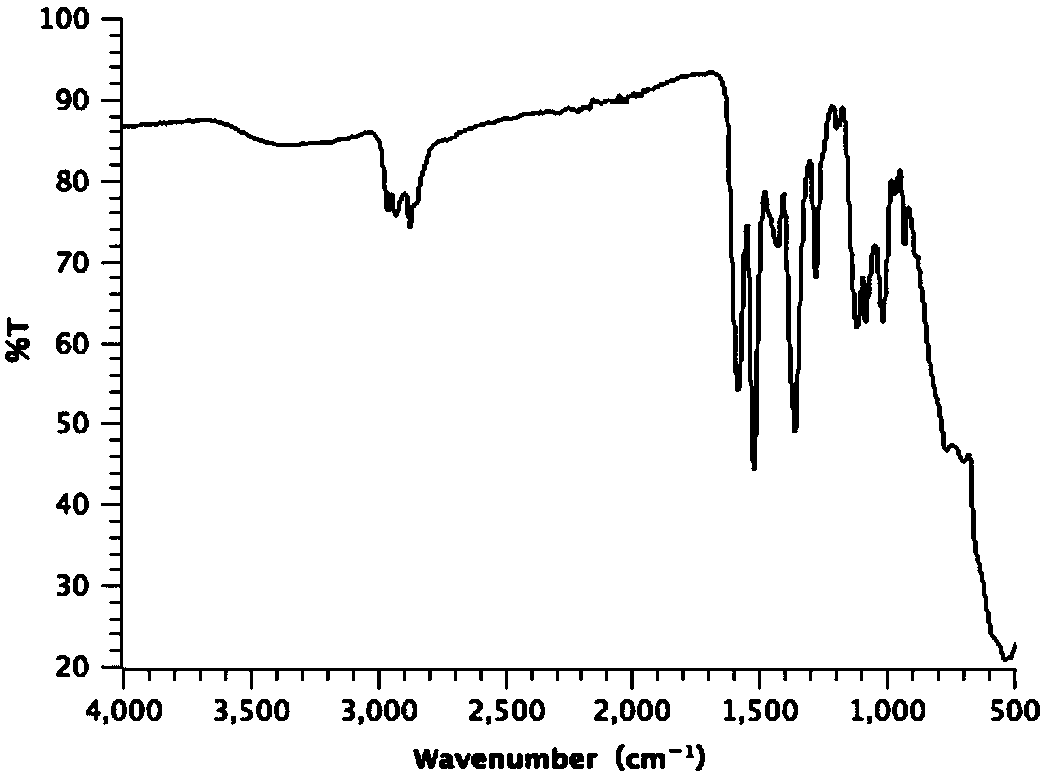

[0079] Grind 1-2 mg of the obtained titanyl polymer and 200 mg of pure KBr evenly, place it in a mold, and press it into a transparent sheet on a tablet machine for IR spectrum characterization, see Figure 2-1 ;

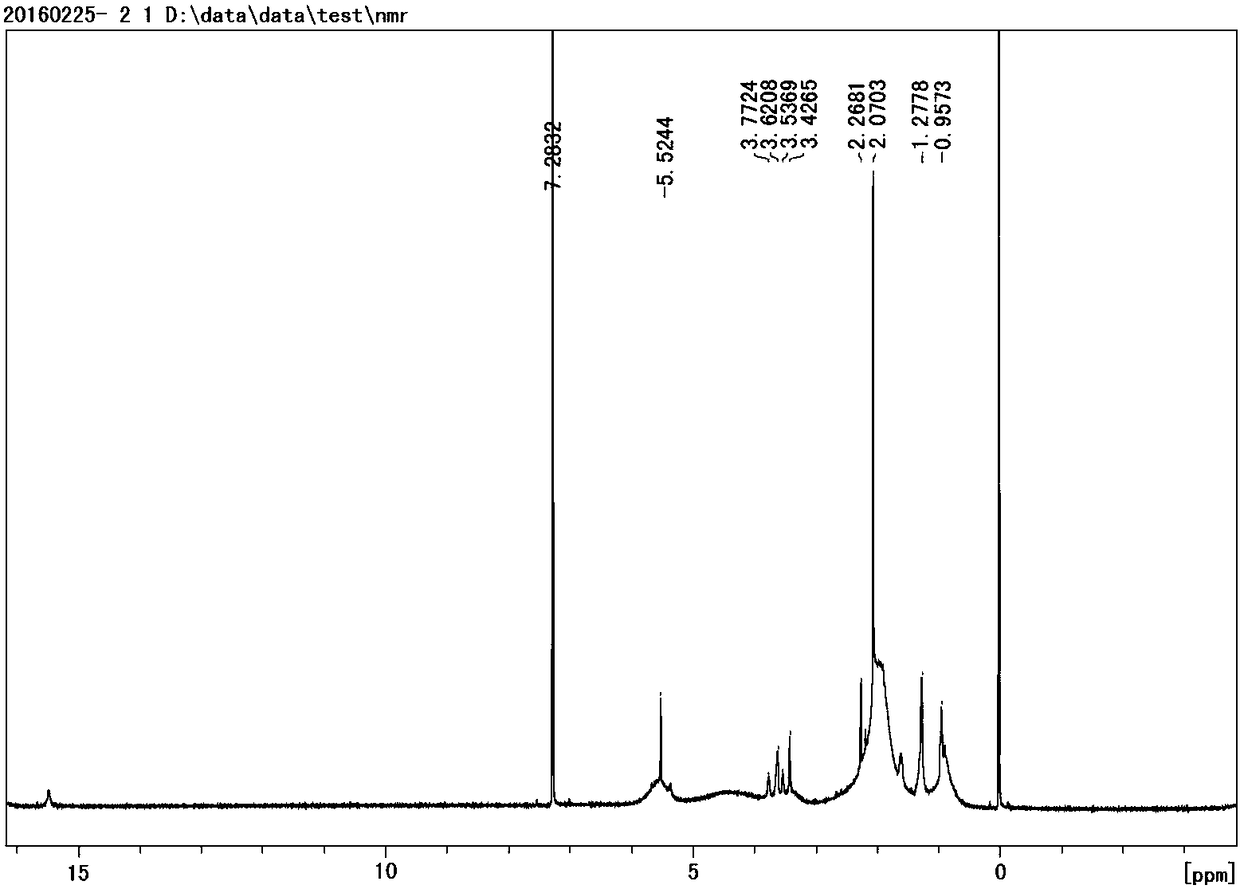

[0080] The resulting titanyl polymer was dissolved in deuterated chloroform for NMR characterization, the results are shown in F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com