Method for preparing flame-retardant cotton fabric without solvents

A solvent-free technology for cotton fabrics, applied in the direction of flame-retardant fibers, plant fibers, textiles and papermaking, etc., can solve the problems of formaldehyde residue and formaldehyde release, and achieve the effect of excellent washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A solvent-free method for preparing a flame-retardant finishing agent for cotton fabrics, the specific steps are:

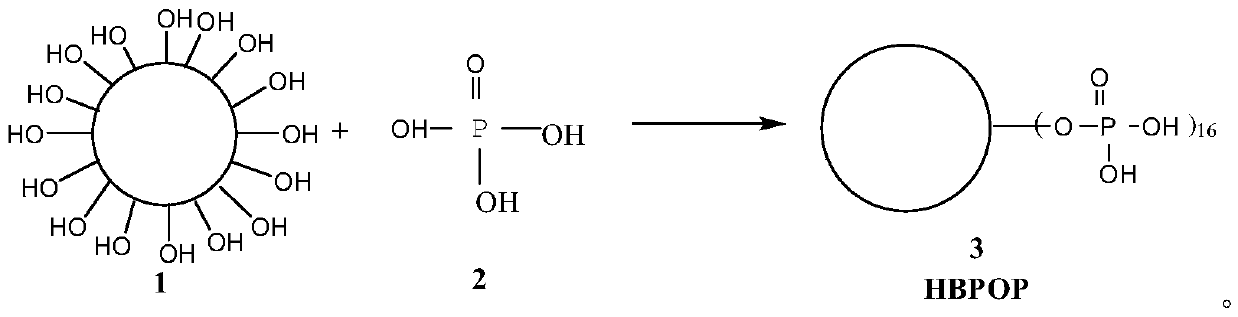

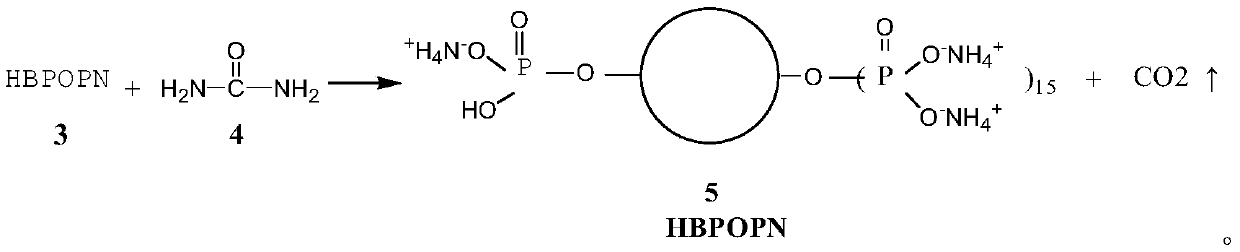

[0025] (1) The hyperbranched polyester and phosphoric acid are mixed at a molar ratio of 1:16, continuously stirred, and reacted for 3 hours at 120° C. to obtain a phosphorus-containing hyperbranched polyester;

[0026] (2) Add urea to phosphorus-containing hyperbranched polyester, the molar ratio of phosphorus-containing hyperbranched polyester to urea is 1:16, condense and reflux at 100°C, react for 1 hour, precipitate with ethanol, separate and purify the Phosphorus and nitrogen hyperbranched polyester are dried in a vacuum oven at 80°C for subsequent use;

[0027] (3) Dissolve the phosphorus-containing and nitrogen-containing hyperbranched polyester in deionized water, add dicyandiamide with a solution quality of 5wt%, and soak the cotton fabric in the above solution with a bath ratio of 1:20, and soak it at 70°C After 30 minutes, the cotton fabric wa...

Embodiment 2

[0029] A solvent-free method for preparing a flame-retardant finishing agent for cotton fabrics, the specific steps are:

[0030] (1) The hyperbranched polyester and phosphoric acid are mixed in a molar ratio of 1:16, continuously stirred, and reacted for 3 hours at 130° C. to obtain a phosphorus-containing hyperbranched polyester;

[0031] (2) Add urea to phosphorus-containing hyperbranched polyester, the molar ratio of phosphorus-containing hyperbranched polyester to urea is 1:16, condense and reflux at 100°C, react for 1 hour, precipitate with ethanol, separate and purify the Phosphorus and nitrogen hyperbranched polyester are dried in a vacuum oven at 80°C for subsequent use;

[0032] (3) Dissolve the phosphorus-containing and nitrogen-containing hyperbranched polyester in deionized water, add dicyandiamide with a solution quality of 5wt%, and soak the cotton fabric in the above solution with a bath ratio of 1:20, and soak it at 70°C After 30 minutes, the cotton fabric wa...

Embodiment 3

[0035] A solvent-free method for preparing a flame-retardant finishing agent for cotton fabrics, the specific steps are:

[0036] (1) The hyperbranched polyester and phosphoric acid are mixed at a molar ratio of 1:16, continuously stirred, and reacted for 3 hours at 140° C. to obtain a phosphorus-containing hyperbranched polyester;

[0037] (2) Add urea to phosphorus-containing hyperbranched polyester, the molar ratio of phosphorus-containing hyperbranched polyester to urea is 1:16, condense and reflux at 100°C, react for 1 hour, precipitate with ethanol, separate and purify the Phosphorus and nitrogen hyperbranched polyester are dried in a vacuum oven at 80°C for subsequent use;

[0038] (3) Dissolve the phosphorus-containing and nitrogen-containing hyperbranched polyester in deionized water, add dicyandiamide with a solution quality of 5wt%, and soak the cotton fabric in the above solution with a bath ratio of 1:20, and soak it at 70°C After 30 minutes, the cotton fabric wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com