Overloaded ground foundation structure of soft foundation seepage-proofing area and treatment method of overloaded ground foundation structure

A technology for weak foundations and areas, applied in foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of insufficient foundation structure strength and bearing capacity, weak foundation deformation and creep control ability, and large pile foundation investment. , to achieve the effect of shortening the construction period of piles, reducing the number of piles, and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

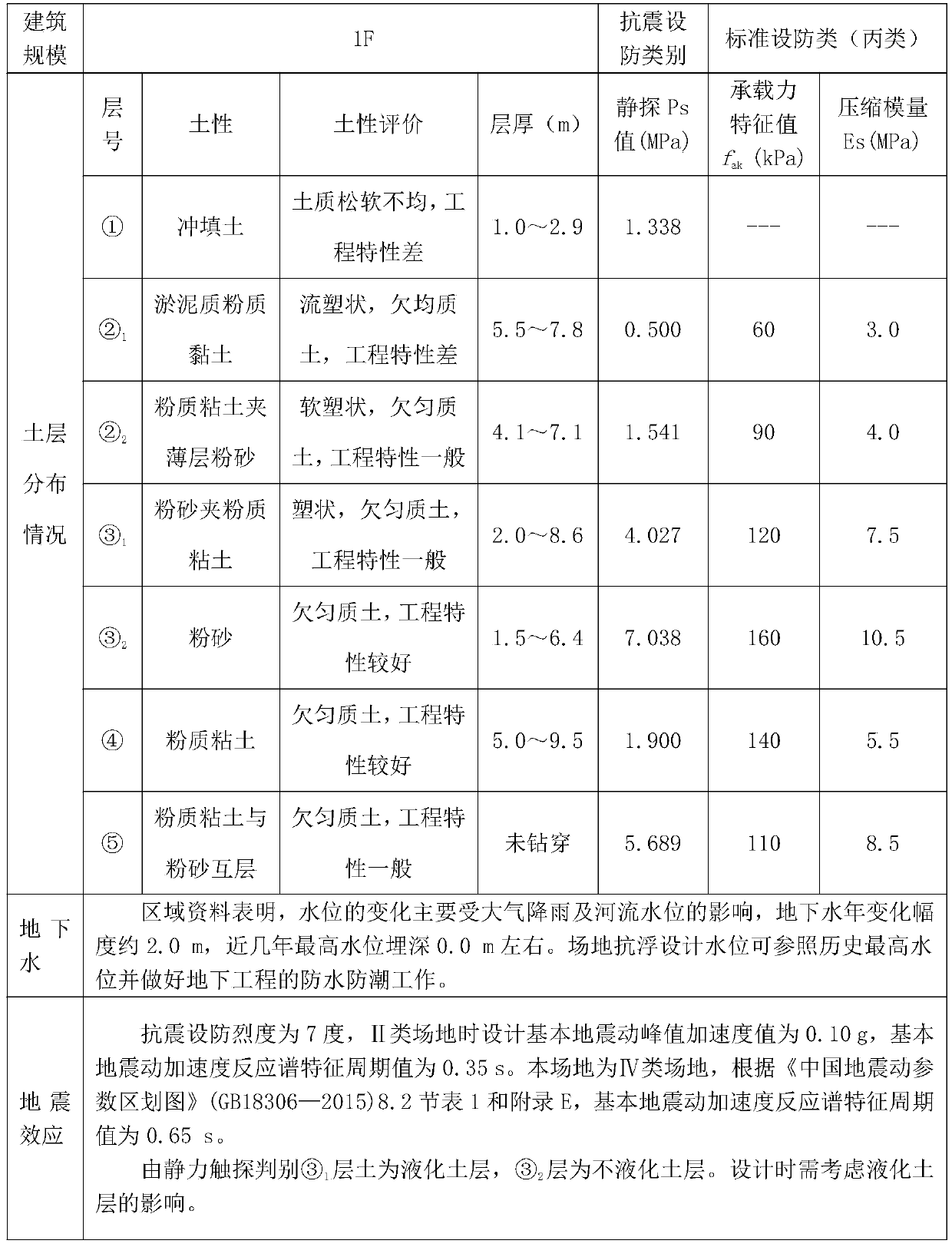

[0038] A certain project is located at the mouth of the Yangtze River. It is a hazardous solid waste warehouse, and anti-seepage treatment is required in accordance with environmental protection requirements. The size of the warehouse is 33×285=9405m 2 , the ground load is 8t / m 2 consider. According to the engineering survey report, the soil layer distribution of this project is as follows:

[0039]

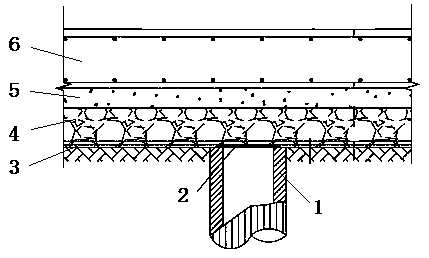

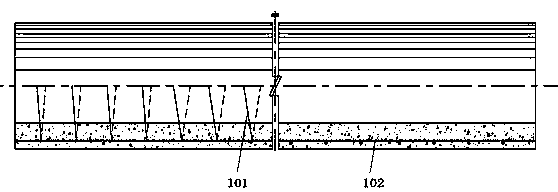

[0040] According to the above survey report, the prestressed thin-walled pipe pile 1 used in this project has a diameter of 400mm, a wall thickness of 60mm, a pile spacing of 1.8m, and a pile length of 12m. Other foundation structure settings and foundation treatment methods are as described above. This project uses prestressed thin-walled pipe piles as the vertical reinforcement in the composite foundation, which can ensure that the ground load requirements are met; at the same time, two layers of unidirectional polyester fibers are laid on the top surface of prestressed th...

Embodiment 2

[0042] A certain project is a hazardous solid waste warehouse, and anti-seepage treatment is required according to environmental protection requirements. The size of the warehouse is: 30×60=180m 2 , the ground load is 12t / m 2consider. The proposed site is flat and open, the ground elevation of the site varies from 3.70m to 4.61m, and the ground elevation of the orifice varies from 3.75m to 4.51m. According to the design requirements, the outdoor design leveling elevation of the proposed site is 5.15m~5.30m, so most of the proposed site still needs to be filled with about 0.70m~1.80m. The foundation soil layer of the proposed site is artificially filled sand on the surface, mainly siltation, alluvial origin and granite weathered rock formations. The basement rock of the site is granite formed in the late Yanshan period, and the original landform belongs to the coastal terrace landform unit. According to the engineering survey report, the specific distribution of soil layers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com