Anchoring-type hydraulic casing shaping tool

A fixed and hydraulic technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of low power motor power, unable to continue the mining work, stratum dislocation and collapse, etc., to achieve the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

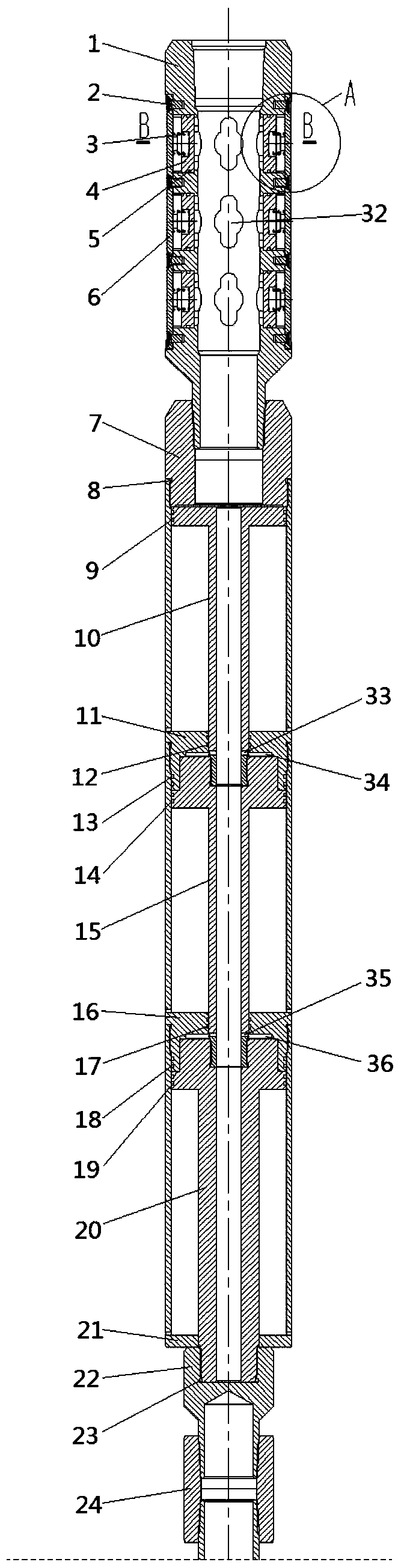

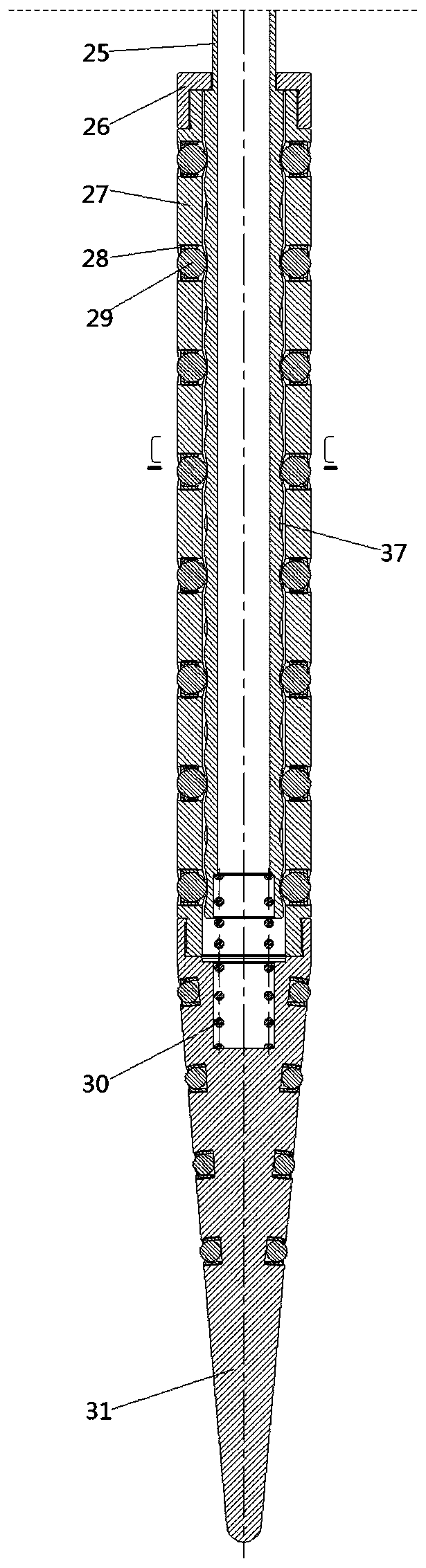

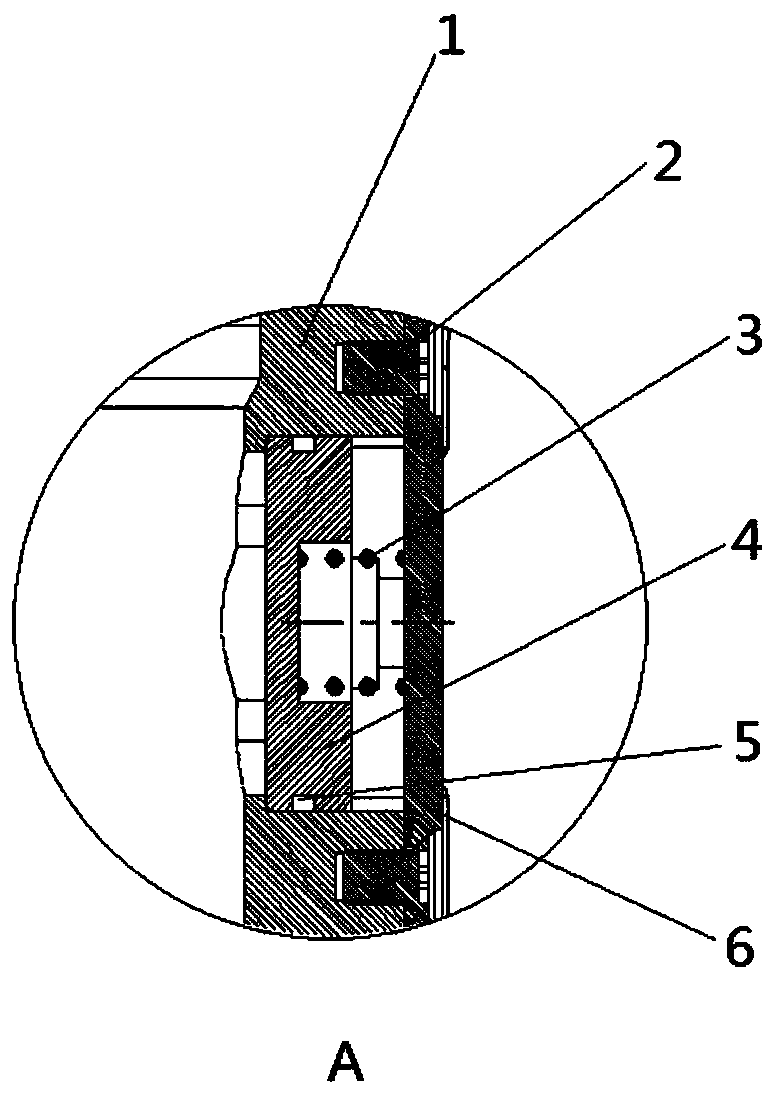

[0023] see Figure 1~6, in an embodiment of the present invention, an anchored hydraulic casing shaping tool includes an anchor body 1, an internal thread 1 is provided on the inner wall of the anchor body 1, and the anchor body 1 can be connected to an external oil pipe through the internal thread 1, The outer wall of the anchor body 1 is provided with a plurality of fluke holes, the plurality of fluke holes are provided with flukes 4, the inside of the fluke 4 is provided with a return spring 3, and the anchor body 1 is also fixed A pressure plate 6 is connected, and the connection mode between the pressure plate 6 and the anchor body 1 is not limited. In this embodiment, preferably, the pressure plate 6 and the anchor body 1 are fixedly connected by a plurality of fixing pins 2, and the The pressure plate 6 has a fixing effect on the return spring 3 and a limiting effect on the anchor fluke 4. The outer wall of the lower end of the anchor body 1 is provided with an upper jo...

Embodiment 2

[0027] In order to make the connection between the various components in the anchored hydraulic casing shaping tool more tightly, this embodiment makes the following improvements on the basis of embodiment 1. The improvements are: the outer wall of the anchor fluke 4 is connected to the A sealing ring 1 is arranged between the anchor holes of the outer wall of the body 1, and a sealing ring 2 8 is arranged between the outer wall of the lower end of the upper joint 7 and the inner wall of the upper end of the upper hydraulic cylinder 11, and the outer wall of the upper end of the upper piston 10 is connected to the inner wall of the upper hydraulic cylinder. 11, a sealing ring 3 9 is arranged between the inner walls of the upper end, and a plurality of sealing rings 4 12 are arranged between the outer wall of the lower end of the upper piston 10 and the inner wall of the lower end of the upper hydraulic cylinder 11. In this embodiment, preferably, the sealing ring 4 The number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com