Camshaft unit and method for producing a camshaft unit

A technology of camshaft and camshaft adjuster, which is applied in the direction of camshaft drive, engine components, engine sealing, etc. It can solve the problems of unidentifiable, seal damage, hydraulic fluid leakage, etc., and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

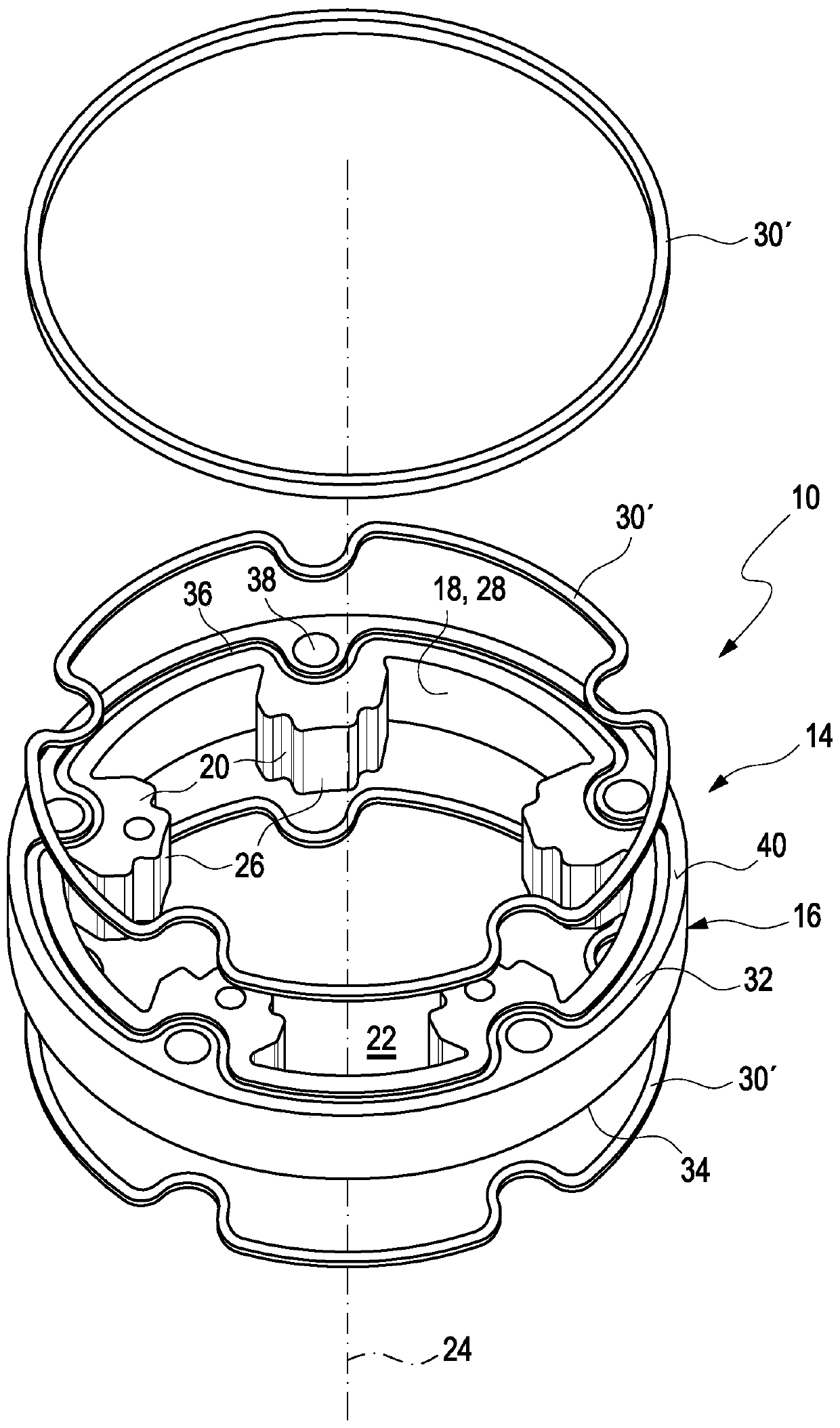

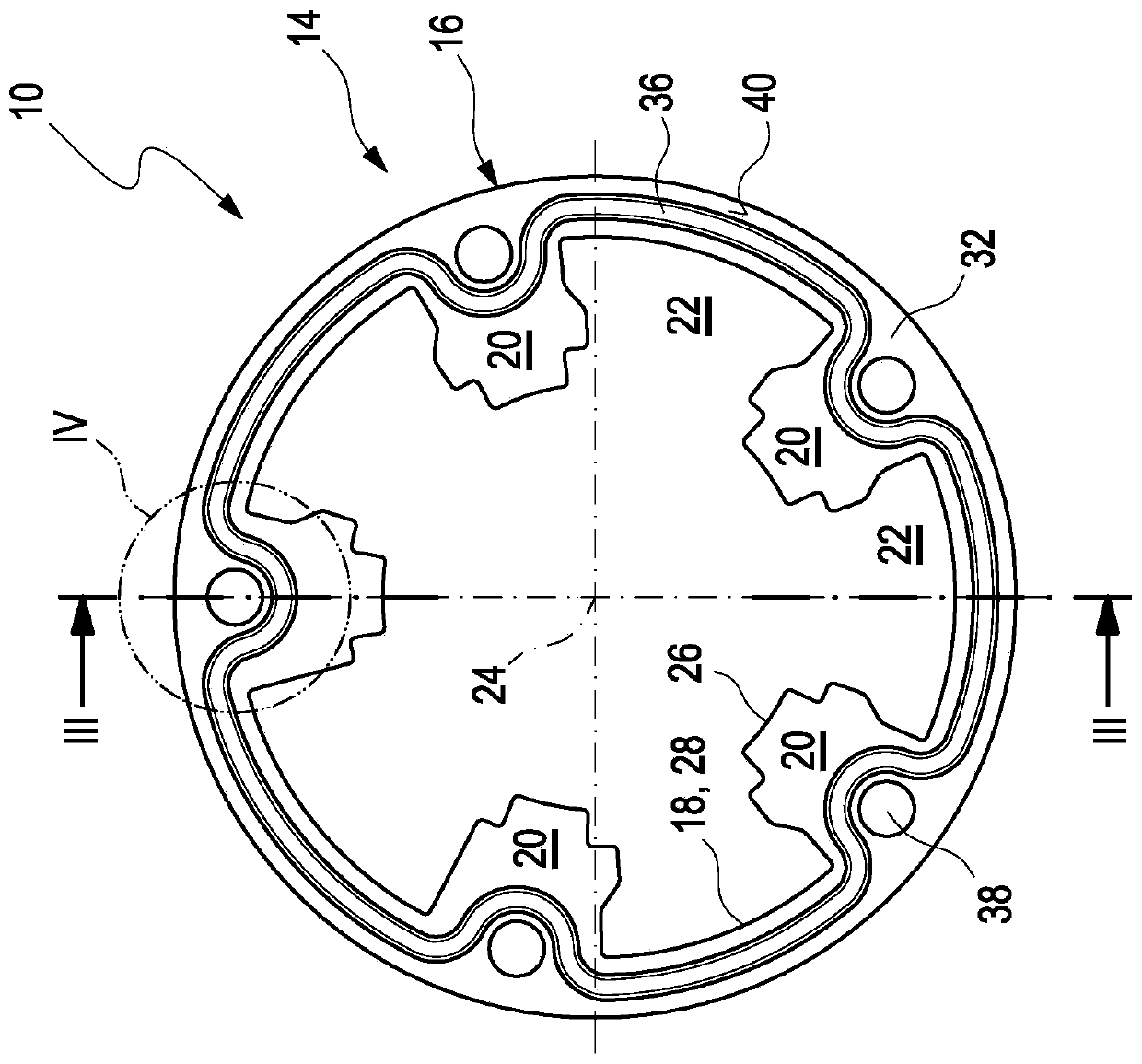

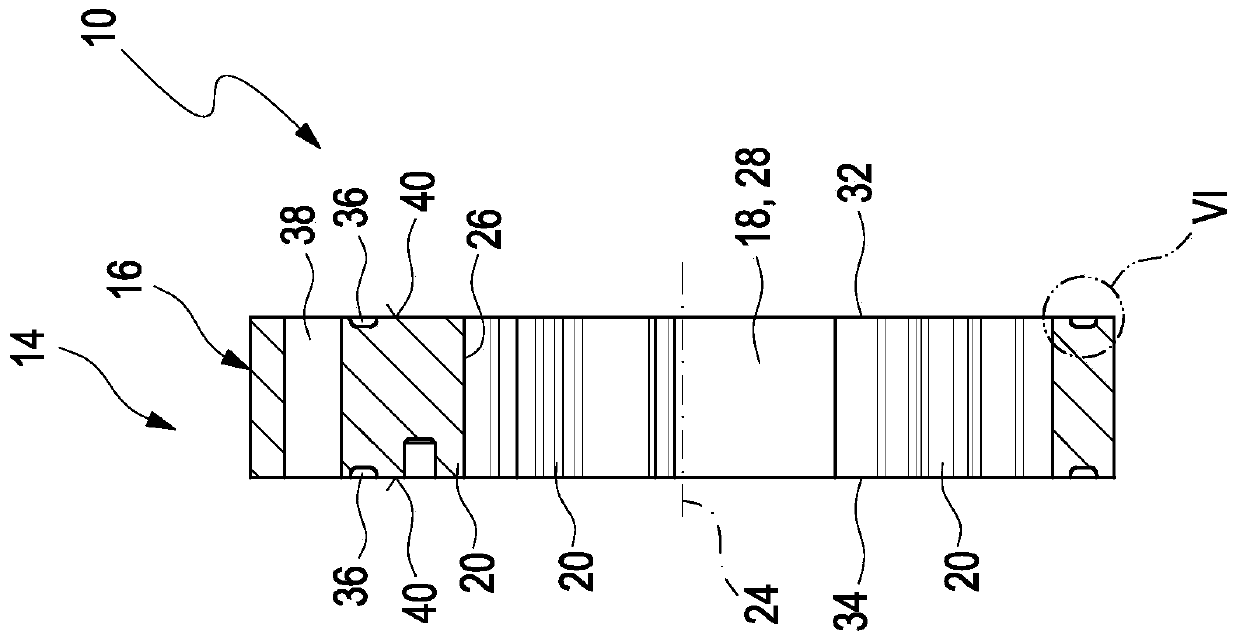

[0027] A camshaft unit 10 constructed according to the prior art is constructed in the form of a camshaft adjuster whose stator 14 is constructed according to FIG. 1 . The camshaft adjuster 10 can bring about a change in the opening and closing times of the gas exchange valves of the internal combustion engine during the operation of the internal combustion engine (not shown in detail).

[0028] FIG. 9 shows a further prior art camshaft adjuster 10 in an exploded view. This shows by way of example a typical construction of a camshaft adjuster 1 , wherein the invention is not, however, restricted to this construction.

[0029] For this purpose, the relative angular position of a camshaft (not shown in detail) of the internal combustion engine relative to a crankshaft (not shown in detail) of the internal combustion engine is continuously varied by means of a camshaft adjuster 10 , the camshaft being twisted relative to the crankshaft. The opening and closing times of the gas e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com