Semi-closed compressor gas sucking end cover provided with wiring box

A technology with junction box and junction box, which is applied in the direction of connection, electrical components, mechanical equipment, etc., can solve the problems of insufficient pressure strength of sheet metal parts, short board of suction cavity structure, complex structure, etc., and achieve simple and reliable system structure , Improve the pressure bearing capacity and simplify the shell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

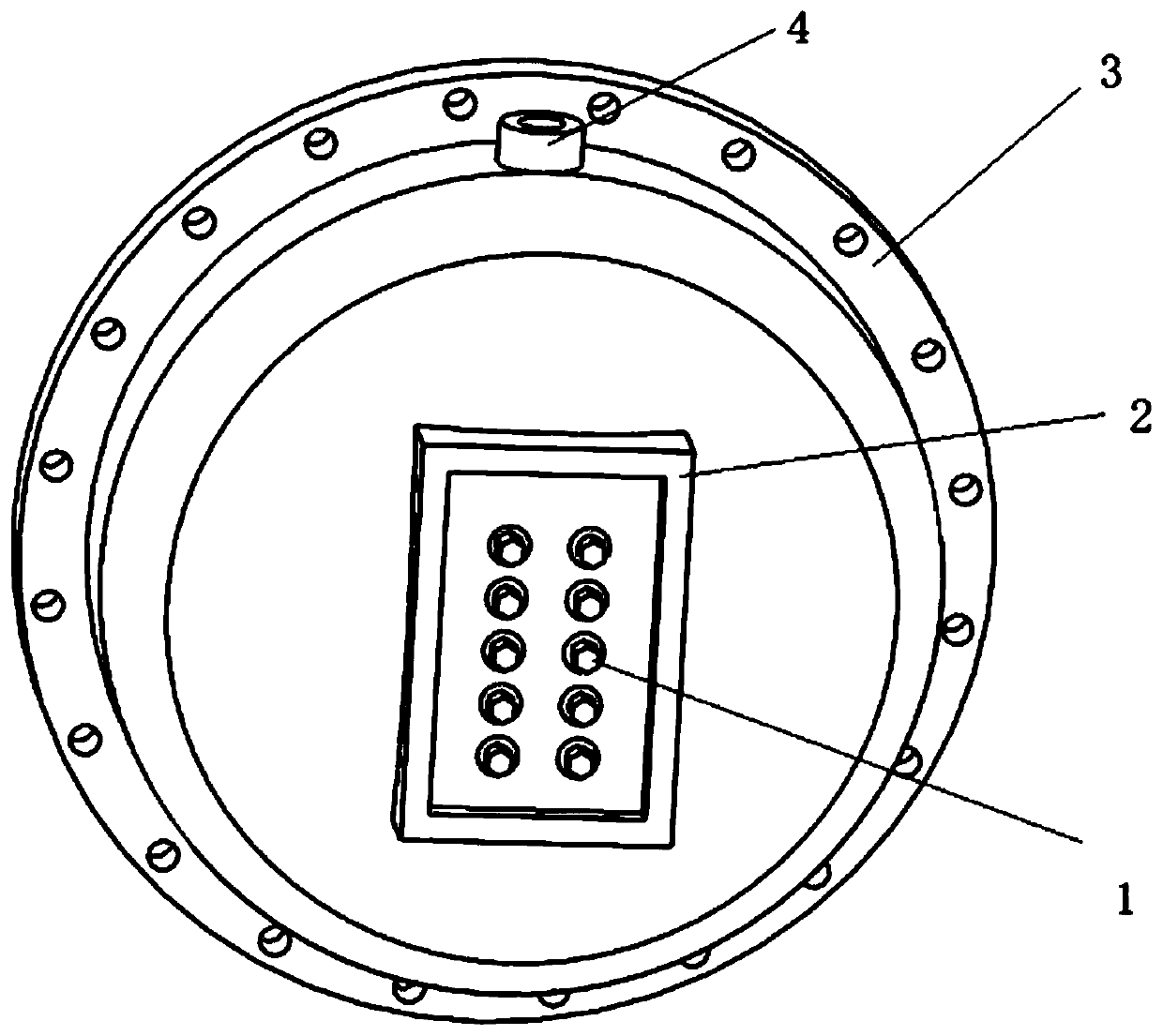

[0015] like figure 1 As shown, the suction end cover of the semi-hermetic compressor with junction box of the present invention includes a main body 3 of the suction end cover, a junction box body 2 and the like. The main body 3 of the suction end cover is one of the main parts of the motor cavity structure. It is integrally cast with the junction box body 2 on the end surface and the opening of the safety relief valve 4. A series of wiring connections are arranged on the junction box body 2. The column is used to connect the cavity with the external environment.

[0016] In the actual operation process, the main body 3 of the suction end cover is connected to the compressor system components through the flange, the high-voltage wire and the control circuit line are connected to the terminal 1 from the outside, and the other end is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap