Intelligent electric actuator of flow monitoring valve

An electric actuator and flow monitoring technology, applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of valve failure, cumbersome assembly, alarm and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

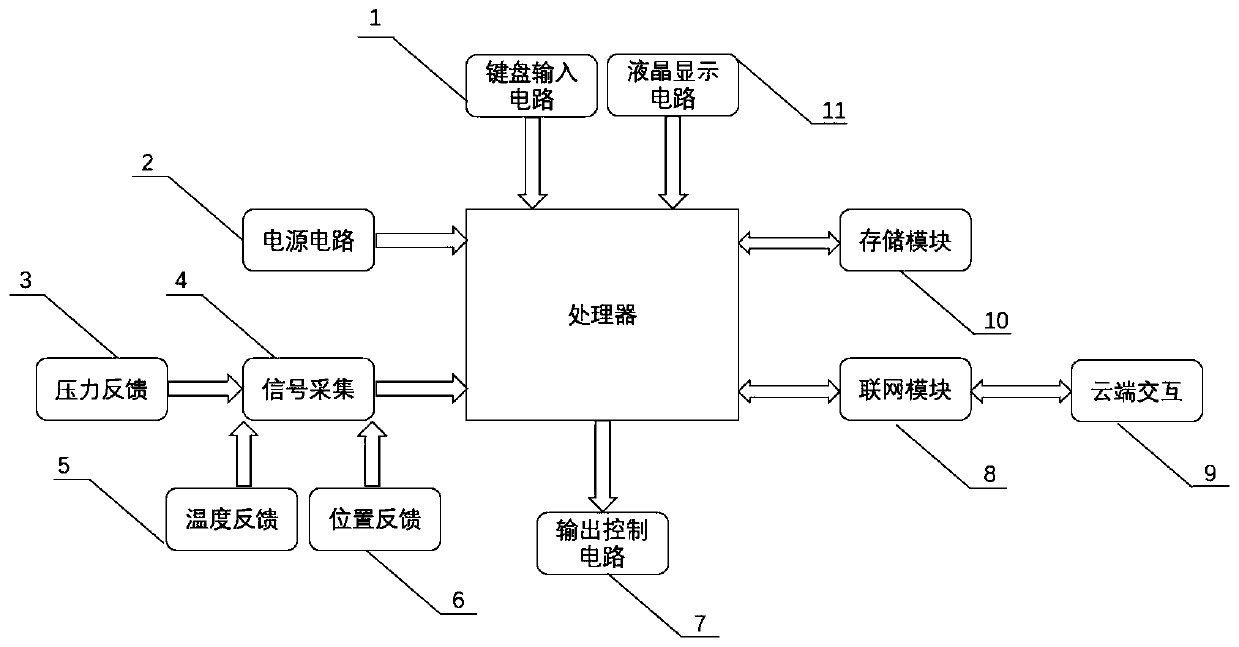

[0029] Specific embodiments of the present invention such as Figure 1-4 Shown is a monitoring electric actuator for an intelligent flow valve, which includes an electric execution unit 16, a control unit, a signal acquisition unit, a human-computer interaction unit 17, a storage unit 10, a cloud interaction unit 9 and a power supply unit 2. The control unit is controlled by a technician Purchasing the processor MCU on the market according to the conventional requirements, the processor MCU is connected with the electric execution unit 16 through the output control circuit 7; when the output control circuit 7 interacts with the processor for data, the communication protocol adopts the MODBUS protocol, and the communication data needs to pass through the CRC of both parties check. Specifically, the MODBUS protocol card adopts a two-wire half-duplex RS485 interface, which can be configured to identify bus parameters such as baud rate, device address, and parity bit. Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com