Full-link dynamic image quality numerical simulation system and method for aerospace camera optical system

An optical system and dynamic simulation technology, which is applied in the fields of optics, optical components, and electrical digital data processing, can solve problems such as difficult single evaluation and complex constraints, and achieve the goals of improving analysis accuracy, optimizing system structure, and shortening the development cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

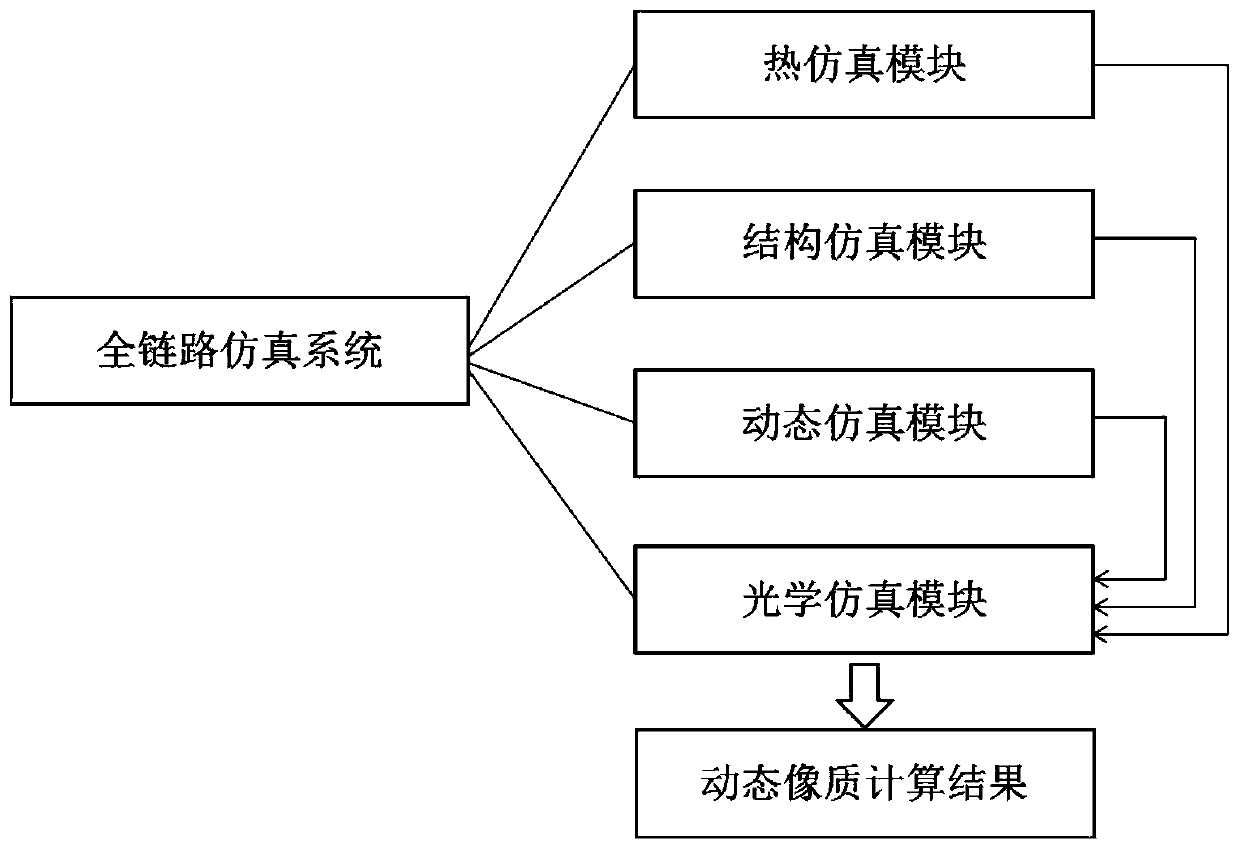

[0034] Specific implementation mode 1. Combination figure 1 To illustrate this embodiment, the full-link dynamic image quality numerical simulation system of an aerospace camera optical system includes four parts: a thermal simulation module, a structural simulation module, a dynamic simulation module, and an optical simulation module; the thermal simulation module is used to simulate the working environment of the camera system temperature field distribution, and calculate the structural deformation of the camera components due to environmental changes; the structural simulation module is used to simulate the structural deformation of the camera system caused by the gravity change in orbit; the dynamic simulation module is used to calculate the structural vibration and vibration of the camera system The amount of structural deformation at each moment in the working state of attitude correction movement;

[0035] The calculation results of the thermal simulation module, the st...

specific Embodiment approach 2

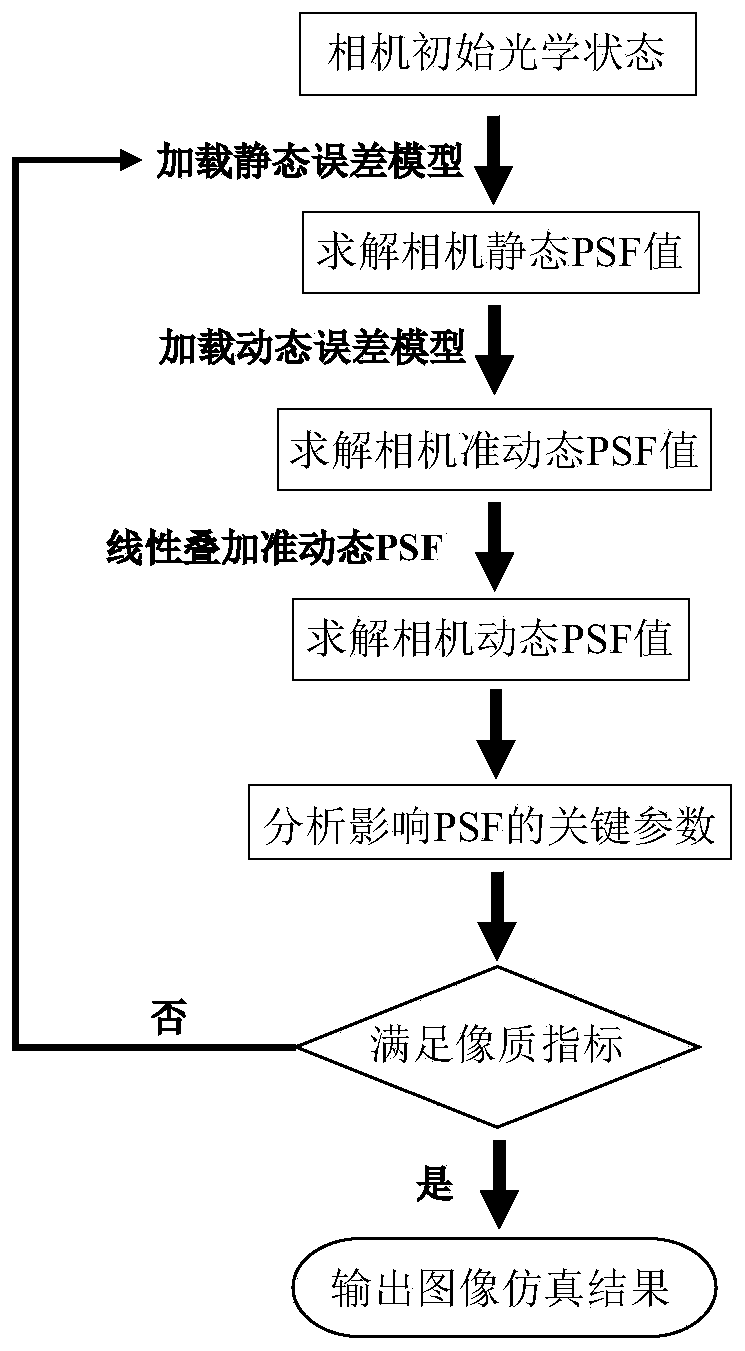

[0036] Specific embodiment two, combine Figure 2 to Figure 14 This embodiment is described. This embodiment is the simulation method of the full-link dynamic image quality numerical simulation system of the aerospace camera optical system described in the first embodiment. The method is implemented by the following steps:

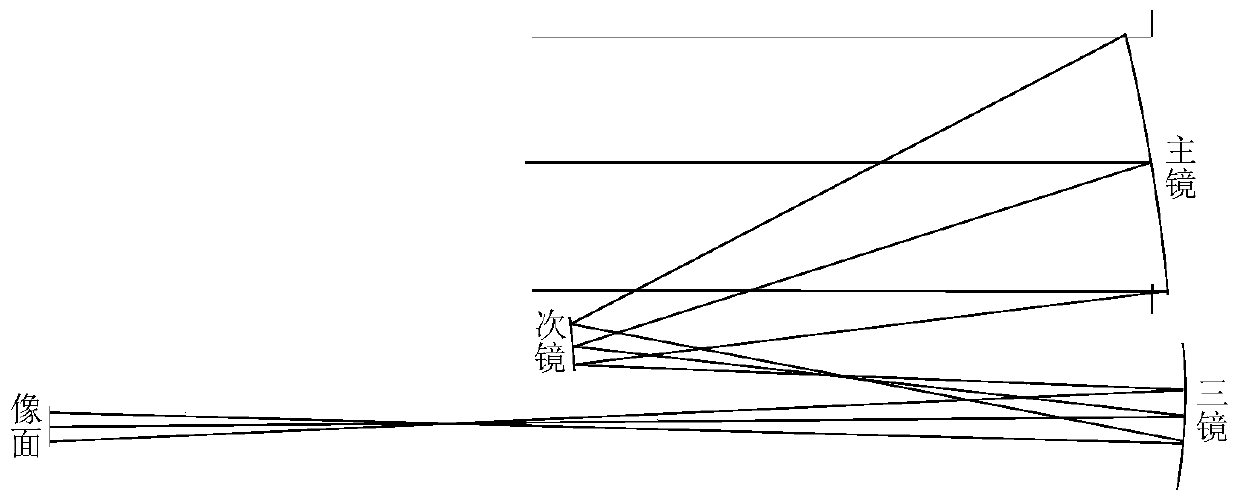

[0037] (1) According to the user's index requirements, design the initial system structure of the camera, optimize the optical parameters in the optical system module, and complete the initial optical design. Take the off-axis three-mirror system as an example, such as image 3 As shown in , the distant parallel light is imaged on the detection image plane after passing through the primary mirror, secondary mirror and third mirror;

[0038] (2) Divide the error models of the on-orbit camera into static error and dynamic error. Among them, taking the primary mirror as an example, the static error mainly includes five items: initial design error, mirror su...

specific Embodiment approach 3

[0043] Specific implementation mode three. This implementation mode is an example of the full-link dynamic image quality numerical simulation method of the aerospace camera optical system described in specific implementation mode two: the specific steps are as follows:

[0044] Step 1. Complete the initial optical design;

[0045] According to the user's demand for camera functions, complete the initial structural design of the system, and assign parameters such as optics, mechanics, and electricity; then optimize the initial optical system of the camera to make the initial design parameters of the system meet the index requirements. In this embodiment, an off-axis three-mirror system is taken as an example for illustration. The parallel light at infinity is imaged on the detection focal plane after passing through the primary mirror, the secondary mirror and the third mirror of the system.

[0046] Step 2. Establish an error model;

[0047] Analyze and establish various error ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com