Surface acoustic wave filter with high temperature stability and preparation method and application thereof

A filter and stability technology, applied in the field of microelectronics, can solve problems such as large temperature coefficient, changes in electrical performance parameters, frequency drift, etc., and achieve stable performance, stability, long service life, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

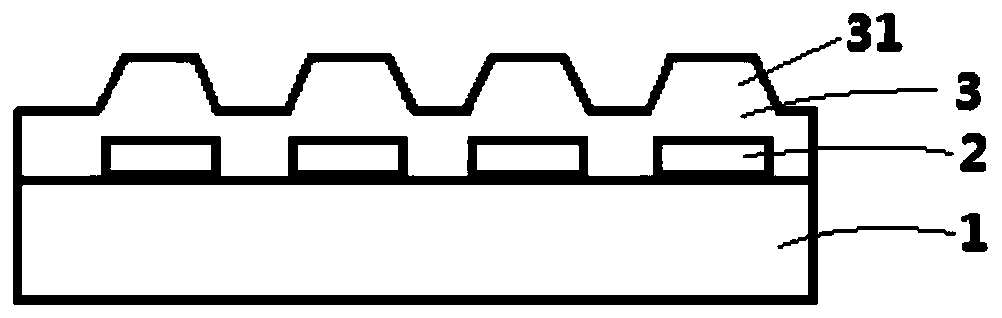

[0034] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned surface acoustic wave filter with high temperature stability. The preparation method of the surface acoustic wave filter combines figure 1 , the process flow of the preparation method of the surface acoustic wave filter is as follows Image 6 As shown, it includes the following steps:

[0035] S01: preparing an IDT electrode 2 on a plane 11 of a piezoelectric substrate 1;

[0036] S02: Deposit an insulating protective film layer on the plane 11 of the piezoelectric substrate 1, and make the insulating protective film layer cover the IDT electrode 2;

[0037] S03: Perform etching treatment on the outer surface of the insulating protection film layer, so that a plurality of protrusions 31 distributed at intervals are formed on the surface.

[0038] Specifically, in the above step S01, the method for preparing the IDT electrode 2 on the piezoelectric substr...

Embodiment 11

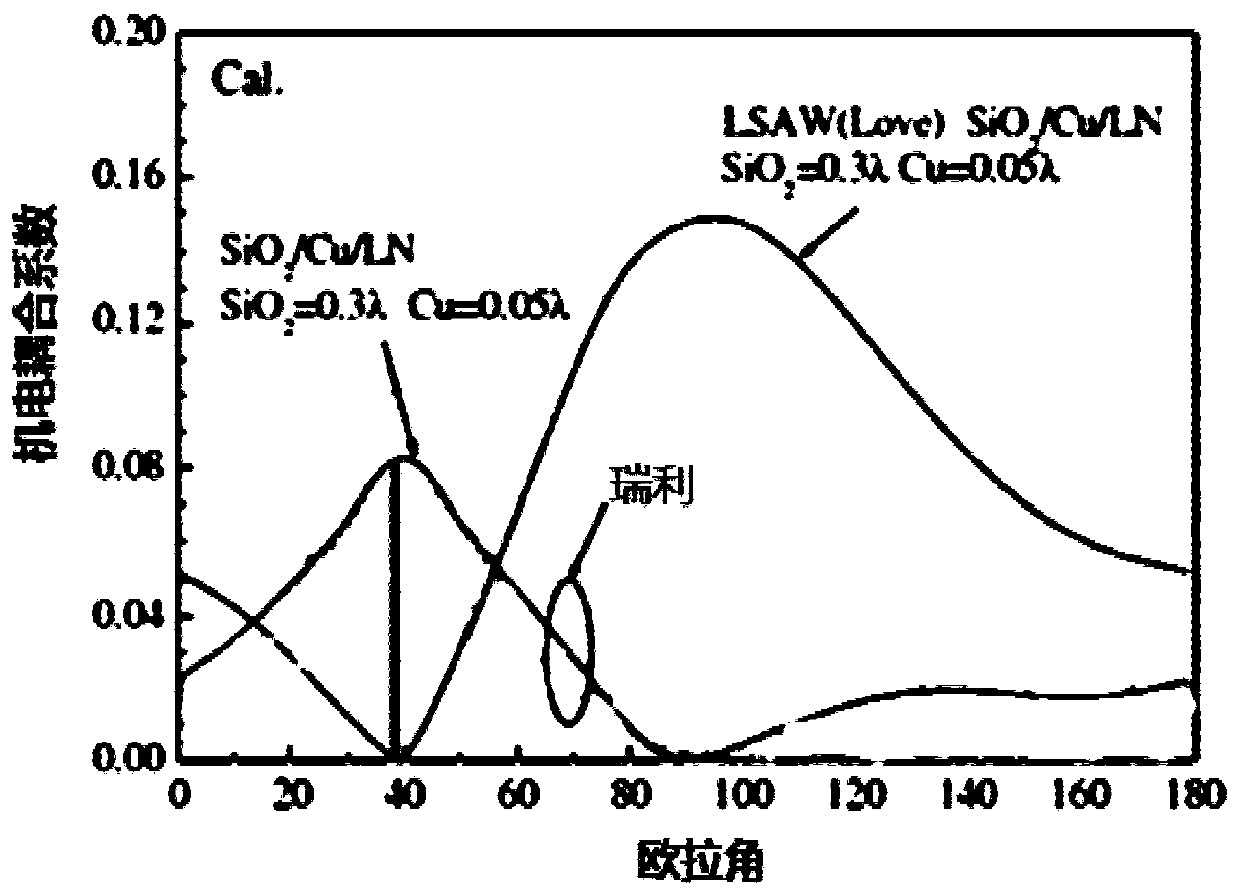

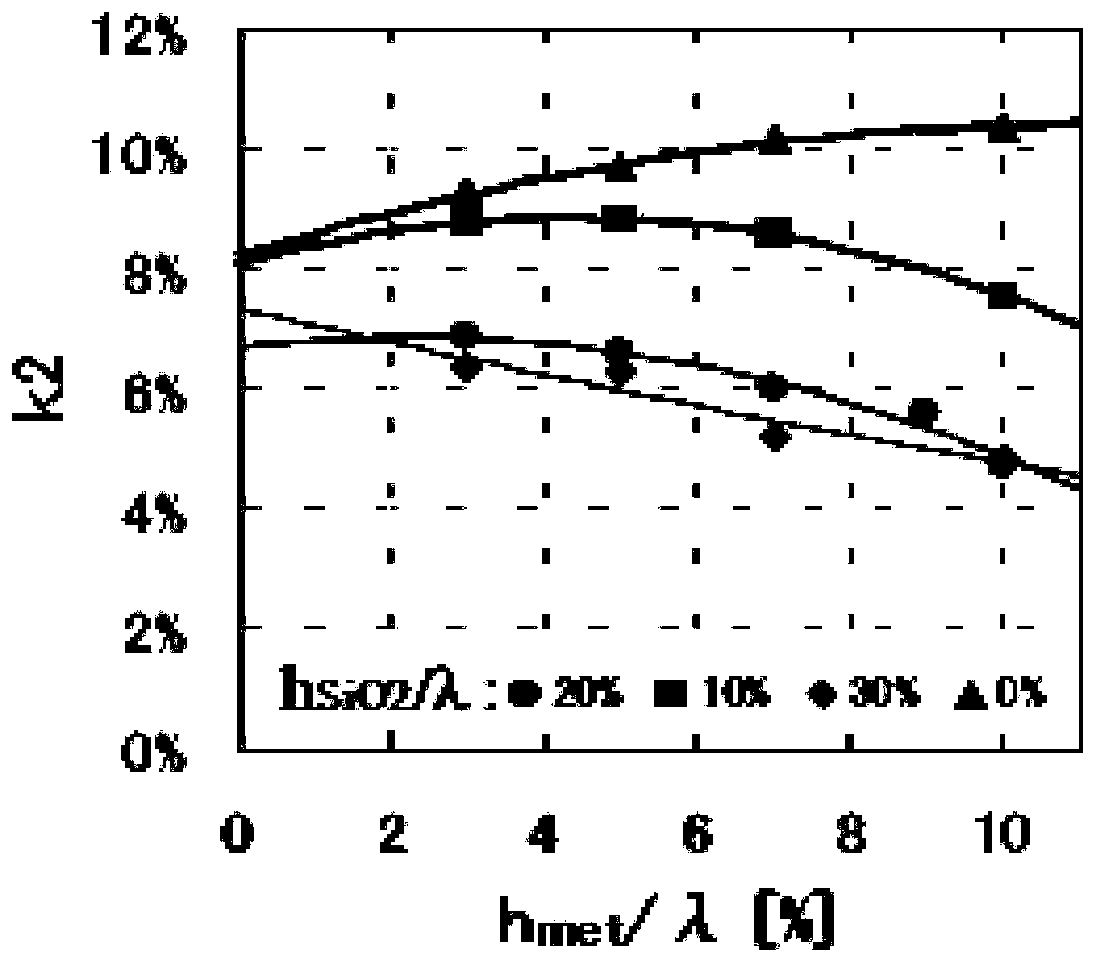

[0064] This embodiment provides a surface acoustic wave filter and a preparation method thereof. The structure of the SAW filter is as figure 1 As shown, the structure of the surface acoustic wave filter is: piezoelectric substrate 1 / interdigital transducer electrodes 2 / insulating protection layer 3 . Wherein, the piezoelectric substrate 1 is LiTaO 3 , its Euler angle (0, θ, 0) θ is 38°; the material of the IDT electrode 2 is copper, and its thickness is 0.05λ; the material of the insulating protection layer 3 is SiO 2 , its total thickness is 0.3λ, and the outer surface of the insulating protective layer 3 is formed with a plurality of projections 31 distributed at intervals, and the position of the formation of the projections 31 is the same as that of the single electrode of the IDT electrode 2 Correspondingly, the distance between adjacent protrusions 31 is 0.6 μm, the width A at the top of the protrusions 31 is smaller than the width B at the root, and the ratio of ...

Embodiment 12

[0066] This embodiment provides a surface acoustic wave filter and a preparation method thereof. The structure of the SAW filter is as figure 1 As shown, the structure of the surface acoustic wave filter is: piezoelectric substrate 1 / interdigital transducer electrodes 2 / insulating protection layer 3 . Wherein, the piezoelectric substrate 1 is LiTaO 3 , its Euler angle (0, θ, 0) θ is 42°; the material of the IDT electrode 2 is Al and Cu alloy, and its thickness is 0.045λ; the material of the insulating protective layer 3 is SiO 2 , its total thickness is 0.31λ, and the outer surface of the insulating protective layer 3 is formed with a plurality of protrusions 31 distributed at intervals, and the positions of the protrusions 31 are formed in the same position as the single electrode of the IDT electrode 2 Correspondingly, the distance between adjacent protrusions 31 is 0.8 μm, the width A at the top of the protrusions 31 is smaller than the width B at the root, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com