Coke green stone high frequency/microwave medium ceramic sintered by low temp. and preparation process thereof

A technology of microwave dielectric ceramics and low-temperature sintering, which is applied in the direction of ceramics and inorganic insulators. It can solve the problems of high sintering temperature, poor microwave dielectric properties, and easy reduction of Q value, etc., and achieve low sintering temperature, low frequency temperature coefficient, The effect of small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

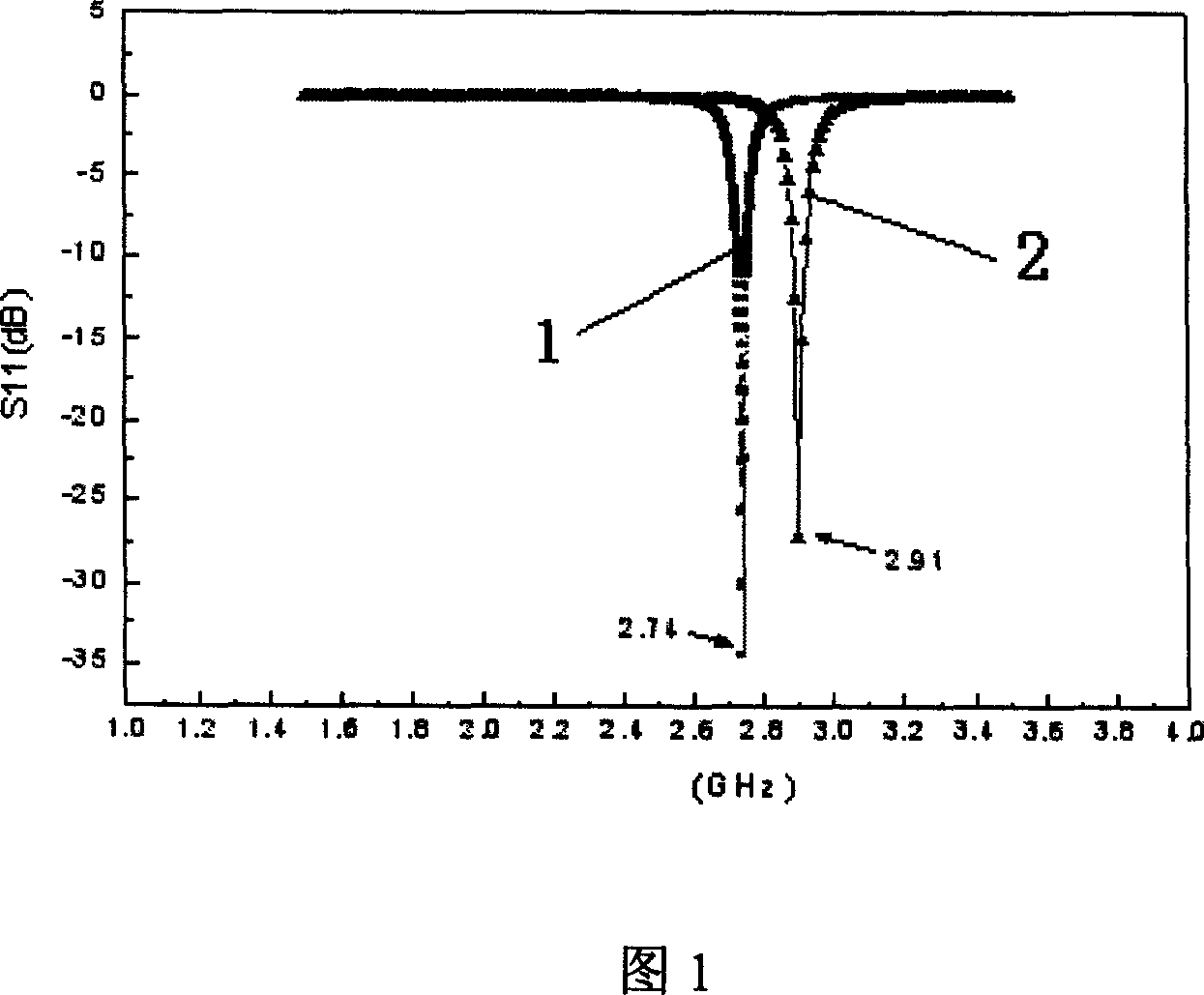

Image

Examples

preparation example Construction

[0025] The preparation process of the present invention is, the chemical raw material Bi 2 o 3 , ZnO, Nb 2 o 5 , CaCO 3 , CdO, SrCO 3 , according to the formula (Bi 3x m 2-3x )(Zn x Nb 2-x )O 7 Preparation, where M=Zn 2+ , Ca 2+ , Cd 2+ ,Sr 2+ , 0.56≤x≤0.64; After the preparation, the ball mill is fully mixed and finely ground, passed through a 70-120 mesh sieve, pre-calcined at 750°C-850°C, and kept warm for 2-3 hours to obtain agglomerates, which are pulverized and ground again Granulate and pass through a 120-mesh sieve to obtain the desired ceramic material. After being made into a finished product as required, it is sintered into porcelain at 900°C to 1020°C to obtain low-temperature sintered pyrochlore high-frequency / microwave dielectric ceramics.

[0026] The low-temperature sintered pyrochlore high-frequency / microwave dielectric ceramics of the present invention include Bi 2 o 3 , ZnO, Nb 2 o 5 Such composition makes it possible to sinter this dielect...

Embodiment 1

[0030] The chemical raw material Bi 2 o 3 , ZnO, Nb 2 o 5 According to the formula: (Bi 3x Zn 2-3x )(Zn x Nb 2-x )O 7 , wherein, x=0.64, after the preparation is fully mixed and ball milled, passed through a 70-120 mesh sieve, pre-fired at 700°C-800°C, and kept warm for 2-3 hours to obtain a briquette, which is pulverized and ground again Granulate and pass through a 120-mesh sieve to obtain the desired ceramic material. After the porcelain material is made into a finished product as required, it is sintered into porcelain at 940°C to 1040°C to obtain low-temperature sintered pyrochlore high-frequency / microwave dielectric ceramics.

[0031] The performance of this group of ceramic materials reaches the following indicators:

[0032] Dielectric constant temperature coefficient α ε =248ppm / ℃(1MHz), dielectric constant ε=84(1MHz), dielectric loss tanδ-4 (1MHz), insulation resistivity ρ v ≥10 14 Ω·cm, good microwave performance ε=75(3~5GHz), Qf=1667.

Embodiment 2

[0034] The chemical raw material Bi 2 o 3 , ZnO, Nb 2 o 5 , CaCO 3 According to the formula: (Bi 3x Ca 2-3x )(Zn x Nb 2-x )O 7 , wherein, x=0.56, after the preparation is fully mixed and ball milled, passed through a 70-120 mesh sieve, pre-calcined at 700°C-800°C, and kept warm for 2-3 hours to obtain a briquette, which is pulverized and ground again Granulate and pass through a 120-mesh sieve to obtain the desired ceramic material. After the porcelain material is made into a finished product as required, it is sintered into porcelain at 900°C to 980°C to obtain low-temperature sintered pyrochlore high-frequency / microwave dielectric ceramics.

[0035] The performance of this group of ceramic materials reaches the following indicators:

[0036] Dielectric constant temperature coefficient α ε =214ppm / ℃(1MHz), dielectric constant ε=80(1MHz), dielectric loss tanδ-4 (1MHz), insulation resistivity ρ v ≥10 14 Ω cm, good microwave performance ε = 76 (3 ~ 5GHz), Qf = 5076,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com