Piezoelectric microphone chip and piezoelectric microphone

A microphone and piezoelectric technology, applied in the direction of piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive transducer microphones, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the sensitivity problem Demand and other issues, to achieve the effect of improving S/N and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, the present invention will be described in more detail with examples and comparative examples given.

[0098] Microphones of Examples 1 to 4 and Comparative Examples 1 to 3 were produced.

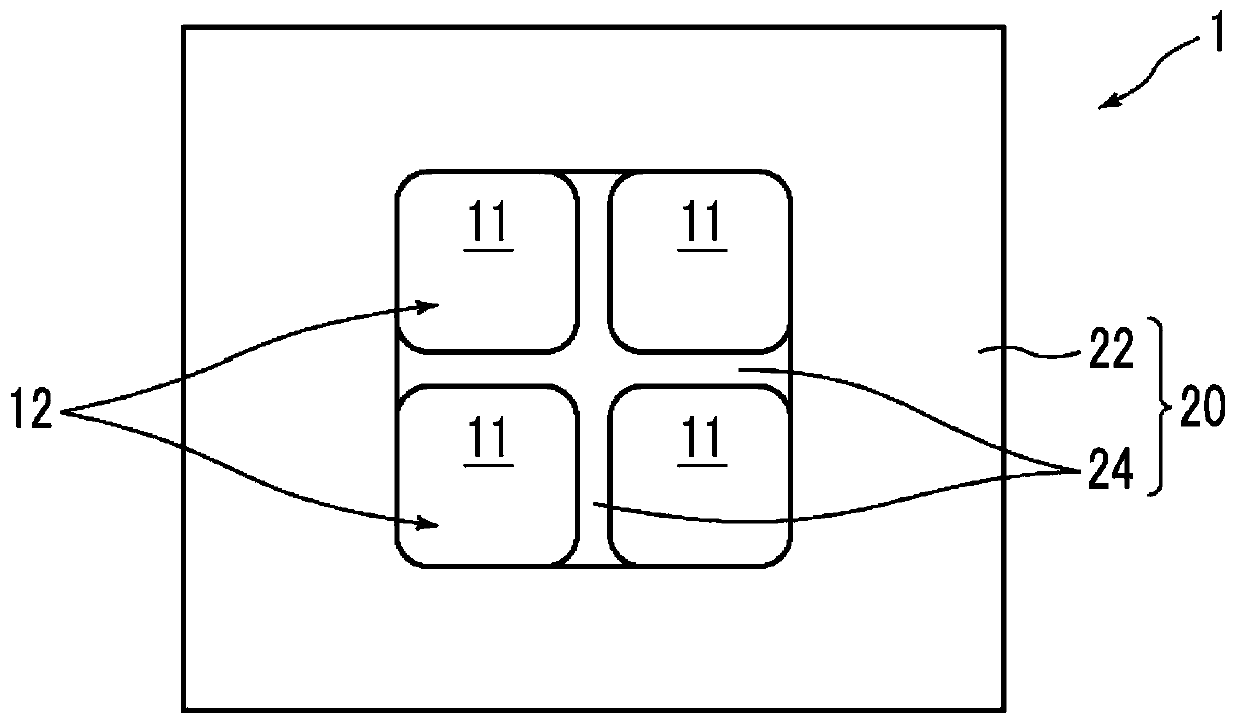

[0099] Figure 11 The dimensions of one spacer and the definitions of the dimensions of a plurality of piezoelectric conversion parts (second electrodes) provided on one spacer in the piezoelectric microphone chips of the examples and comparative examples are shown in . Here, the piezoelectric conversion part a provided in the central part is provided 2 and the four outer piezoelectric conversion parts a arranged around it 11 ~a 14 .

[0100] Let the x-direction length of the separator 51 be Ld x , set the length in the y direction as Ld y . will move toward the central piezoelectric transducer a 2 The x-direction length of is set to Lin x , set the y-direction length to Lin y . In addition, in each example, the piezoelectric conversion part a 2 The region is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com