Orientation analysis meter

An analyzer and orientation technology, which is applied in the field of orientation analyzers, can solve problems such as inability to miniaturize, difficulty in ensuring accuracy, and bulky parts, and achieve the effects of improving S/N, ensuring accuracy, and reducing parts cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

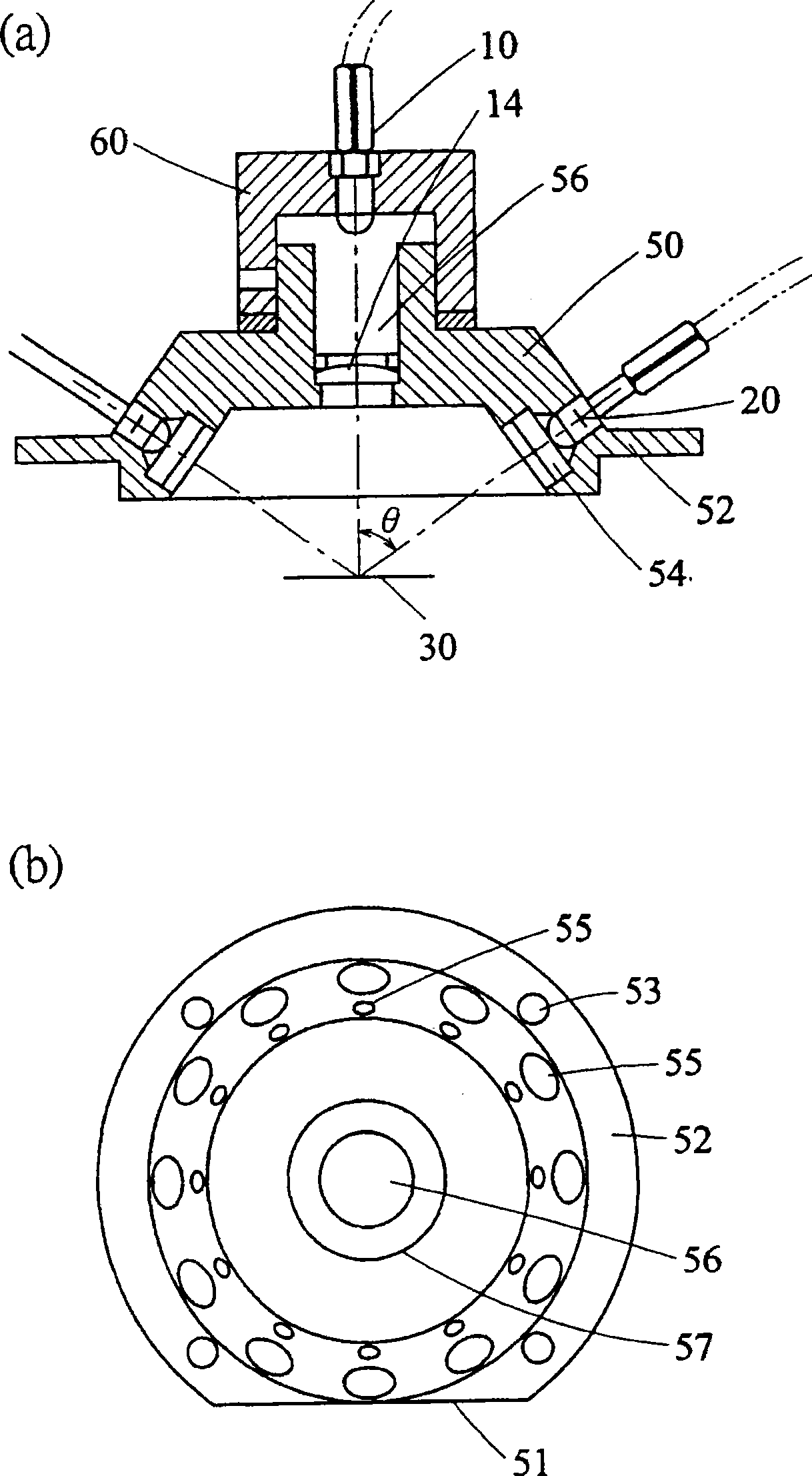

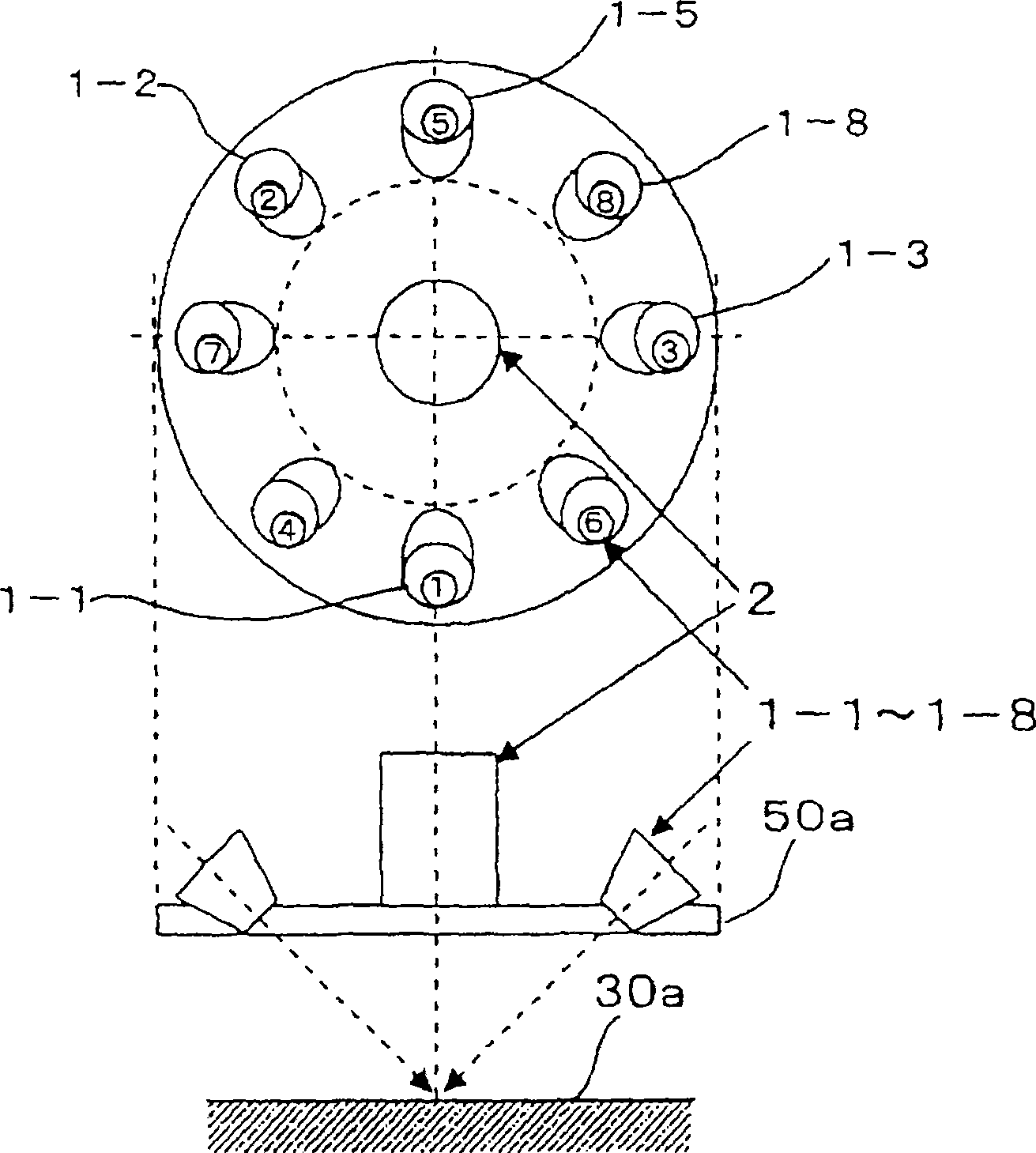

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings. image 3 It is a configuration diagram of an important part of the orientation analyzer related to the present invention.

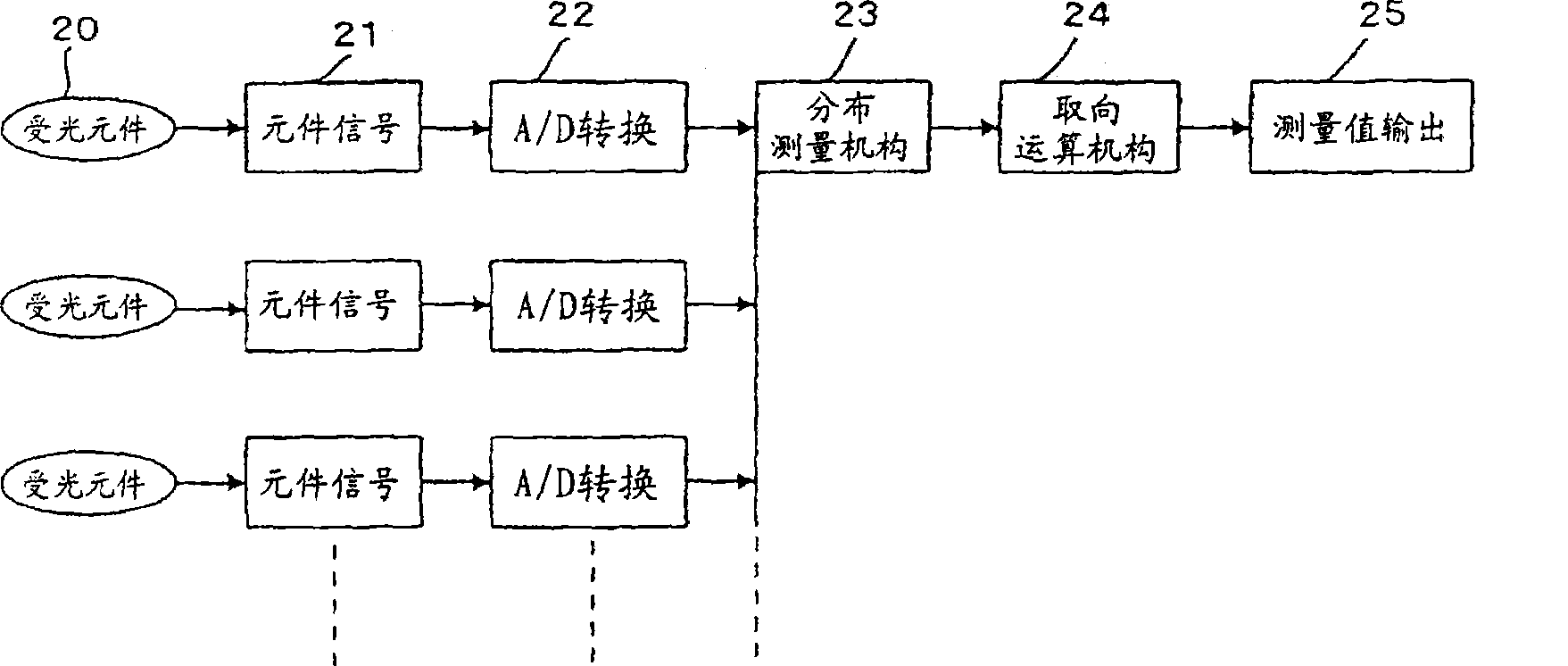

[0071] image 3 Among them, 1-1 to 1-8 are light-emitting modules such as LEDs or lasers, and 50a is a disk-shaped light-emitting module fixing plate. 2 is a light-receiving element composed of a light-receiving diode or the like, and the light-emitting elements 1-1 to 1-8 are arranged at equal intervals around the periphery of the disk-shaped light-emitting element fixing plate 50a. In order to make the light energy emitted by these light-emitting components roughly irradiate the same position of the planar sample 30a, the light-emitting components are arranged at a predetermined angle with the planar sample, and a part of the scattered light reflected by the planar sample 30a will be formed by the arrangement. It is received by the light-recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com