Preparation method of leather scrap composite modified EVA foamed shoe material

A composite modification and leather technology, applied in footwear, application, clothing and other directions, can solve the problems of non-hygroscopic and non-degradable EVA foam materials, and achieve the effects of low cost, alleviation of processing pressure, and uniform and dense product voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of leather shavings composite modified EVA foaming shoe material of the present invention, comprises the following steps:

[0034] Step 1), pulverize the leather solid waste collected from tannery enterprises. First, dry and pulverize the leather solid waste to obtain leather shavings (the finer the pulverization, the more conducive to the banburying operation, the particle size is required to be less than 0.5mm), and then dehydrate the leather shavings. The dehydration treatment method is: weigh A certain amount of leather shavings was dried at 105°C to constant weight, and then dried at 160°C for 2 hours, and the waste leather shavings were packed in an airtight bag and sealed for the next step. In this step, the free moisture is dried at 105°C, and the moisture must be completely removed, otherwise the final product will produce air bubbles due to the presence of moisture, which will affect the product quality. Drying at 160°C is to get ...

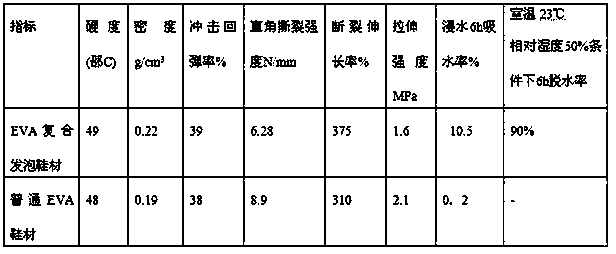

Embodiment 1

[0058] Step 1), dry and pulverize the non-chrome tanned leather solid waste to obtain leather scraps, and then dehydrate the leather scraps: weigh 1000g of leather scraps and dry them at 105°C to constant weight to obtain about 850g of dried leather Dry matter; continue to dry at 160°C for 2 hours to obtain about 810g of dry leather scraps, pack the leather scraps in airtight bags and seal them (to prevent moisture absorption) for the next step.

[0059] Step 2), accurately weigh 800g of leather shavings in step 1) and add it to a high-speed mixer, then add 456g of glycerin, stop stirring for 5 minutes, continue stirring for 5 minutes after 10 minutes, then stop for 10 minutes, continue stirring for 5 minutes, take it out and seal it (to prevent moisture absorption) for the next step.

[0060] Step 3): Accurately weigh 78g of plasticized leather shavings, 200g of EVA and 7g of stearic acid in step 2), add them to the internal mixer, and banbury at 120°C for 4 minutes.

[0061...

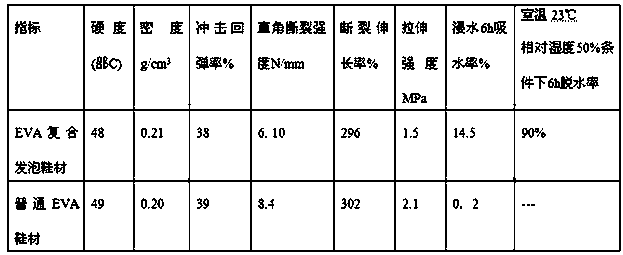

Embodiment 2

[0069] Step 1), dry and pulverize the chrome-tanned leather solid waste to obtain leather scraps, and then dehydrate the leather scraps: weigh 1000g of leather scraps and dry them at 105°C to constant weight to obtain about 845g of dried Continue to dry at 160°C for 2 hours to obtain about 805g of dry leather scraps, pack the leather scraps in airtight bags and seal them (to prevent moisture absorption) for the next step.

[0070] Step 2), accurately weigh 800g of waste leather scraps in step 1) and add it to a high-speed mixer, then add 456g of glycerin, stop stirring for 5 minutes, continue stirring for 5 minutes after 10 minutes, then stop for 10 minutes, continue stirring for 5 minutes, take out the seal (to prevent moisture absorption ) for the next step.

[0071] Step 3): Accurately weigh 68g of plasticized leather shavings, 200g of EVA and 7g of stearic acid in step 2) and add them into the internal mixer, and banbury at 120°C for 4 minutes.

[0072] Step 4) Accurately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com