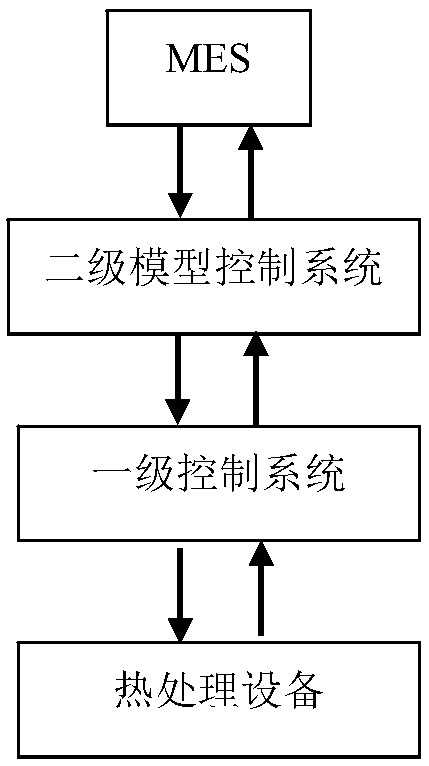

Control method for heat treatment of steel pipe quenching furnace

A control method and quenching furnace technology, applied in the direction of heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problems of difficult operation, high energy consumption, unstable product quality, etc. tracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

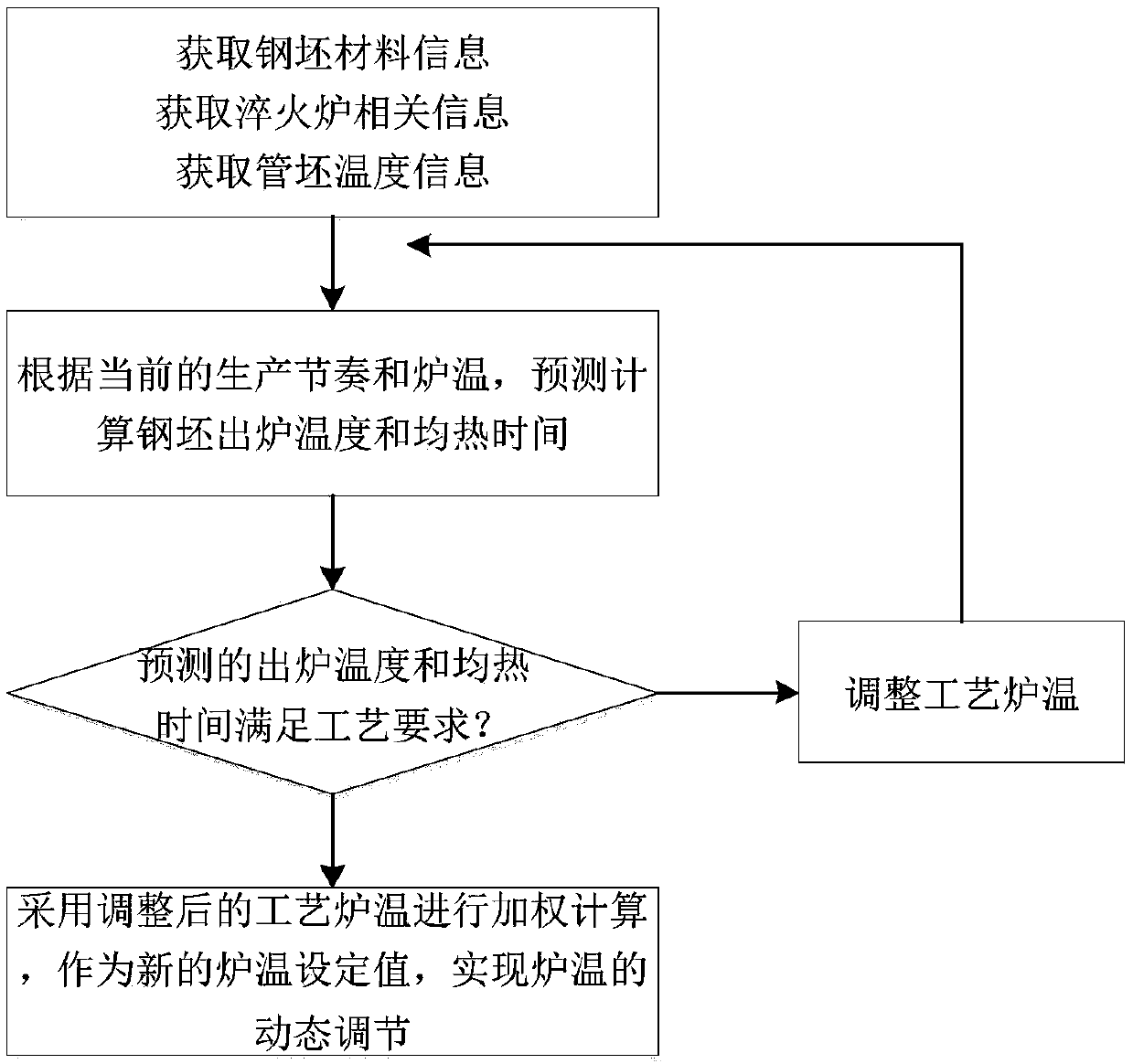

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

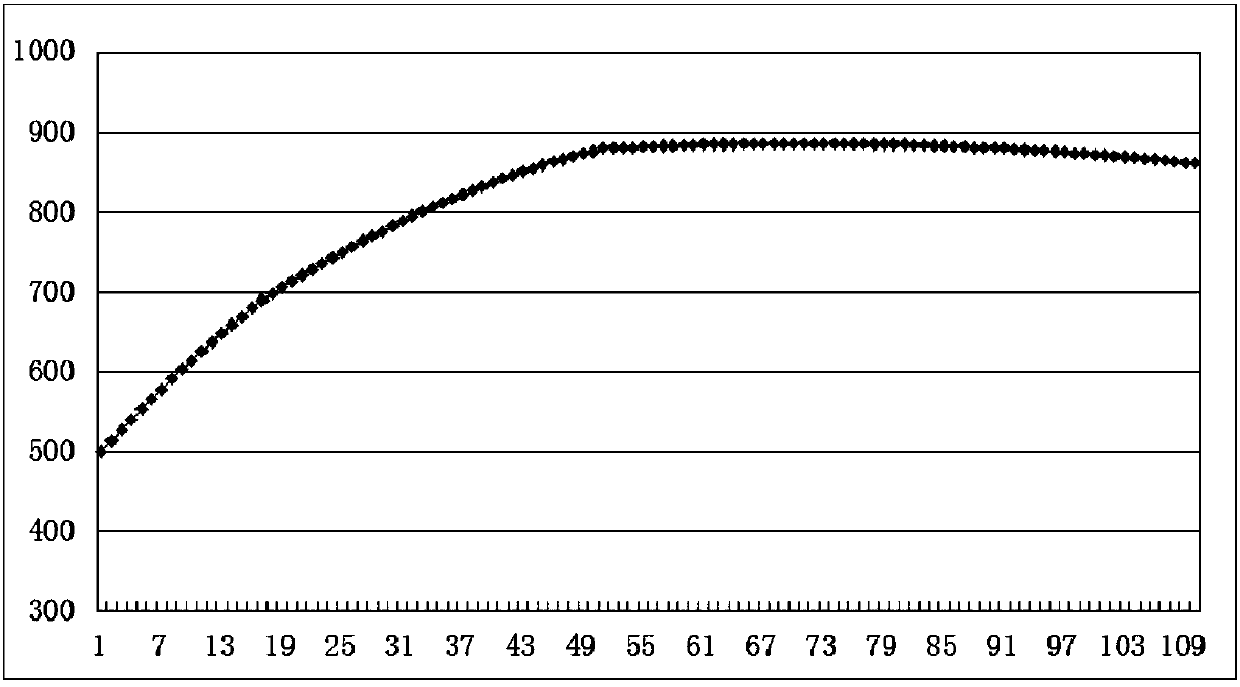

[0084] (1) A quenching furnace has 10 tooth positions, and there are 3 physical sections including the furnace tail section, heating section, and soaking section. The furnace tail section does not control the temperature. The positions of each control section and the thermocouple are as follows, assuming that the furnace The gas temperature is linearly distributed along the position of the thermocouple, see Table 1 for details:

[0085] Table I

[0086]

[0087] (2) The temperature information measured by the thermocouple obtained by L1 is shown in Table 1. The current calorific value is 2800kcal, and the calorific value fluctuation range of the last cycle is within 20kcal, the calorific value fluctuation is small, and the residual oxygen detected by the flue gas is 2 %.

[0088] (3) The steel specifications of all products in the current quenching furnace are the same. The process requires that the temperature of the steel pipe should be >800°C, the corresponding holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com