Antibacterial natural silk fiber product and preparation method thereof

A technology of natural silk and fiber products, applied in the field of fiber production and processing, can solve the problems of insufficient bactericidal ability and insufficient lasting adhesion between silver atom particles and silk fibers, and achieve durable and effective antibacterial properties, strong antibacterial ability and strong adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

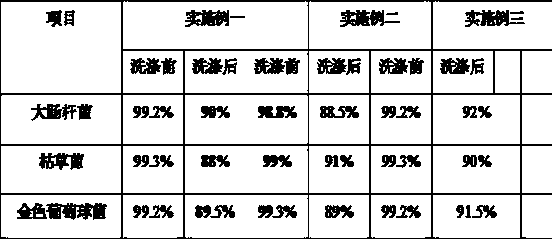

Embodiment 1

[0022] Configuration mass concentration is the formic acid solution of 80%, then in the formic acid solution, add the silver nitrate of 0.5% and the titanium tetrachloride of 0.5%, make treatment liquid after stirring slowly; Natural silk fiber is cleaned, then in 40 degree After soaking in warm water for a period of time, dry it, then put the natural silk fiber into the quaternary ammonium salt solution with a mass concentration of 45% and soak it for a period of time; immerse the processed natural silk fiber product in the treatment solution, and keep it in the dark for 1-20 minutes. 2 days; then the natural silk fiber products are washed and dried to obtain antibacterial natural silk fiber products.

Embodiment 2

[0024] Configuration mass concentration is the formic acid solution of 80%, then in the formic acid solution, add 15% silver nitrate and 15% titanium tetrachloride, make treatment liquid after stirring slowly; Natural silk fiber is cleaned, then in 40 degree After soaking in warm water for a period of time, dry it, then put the natural silk fiber into the quaternary ammonium salt solution with a mass concentration of 45% and soak it for a period of time; immerse the processed natural silk fiber product in the treatment solution, and keep it in the dark for 1-20 minutes. 2 days; then the natural silk fiber products are washed and dried to obtain antibacterial natural silk fiber products.

Embodiment 3

[0026] Configuration mass concentration is the formic acid solution of 80%, then in the formic acid solution, add 7% silver nitrate and 7% titanium tetrachloride, make treatment liquid after stirring slowly; Natural silk fiber is cleaned, then in 40 degree After soaking in warm water for a period of time, dry it, then put the natural silk fiber into the quaternary ammonium salt solution with a mass concentration of 45% and soak it for a period of time; immerse the processed natural silk fiber product in the treatment solution, and keep it in the dark for 1-20 minutes. 2 days; then the natural silk fiber products are washed and dried to obtain antibacterial natural silk fiber products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com