Transparent composite film and flexible display devices including the same

A composite film and transparent technology, applied in textiles, textiles, papermaking, fabrics, etc., can solve problems such as discoloration, increased cost, and limited flexibility of composite products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0076] As used herein, the term "about" means that quantities, dimensions, formulas, parameters, and other quantities and characteristics are not exact and need not be exact, but may be approximate and / or larger or smaller as required, such as reflective tolerances, transformations factors, rounding, measurement errors, etc., and other factors known to those skilled in the art. When the term "about" is used to describe a value or endpoint of a range, it is to be understood that the disclosure includes the specific value or endpoint to which reference is made. Whether or not a range value or endpoint is recited with "about" in the specification, the range value or endpoint is intended to include both embodiments: one modified with "about" and the other unmodified by "about." It is also to be understood that the endpoints of each range are significant relative to, and independent of, the other endpoints.

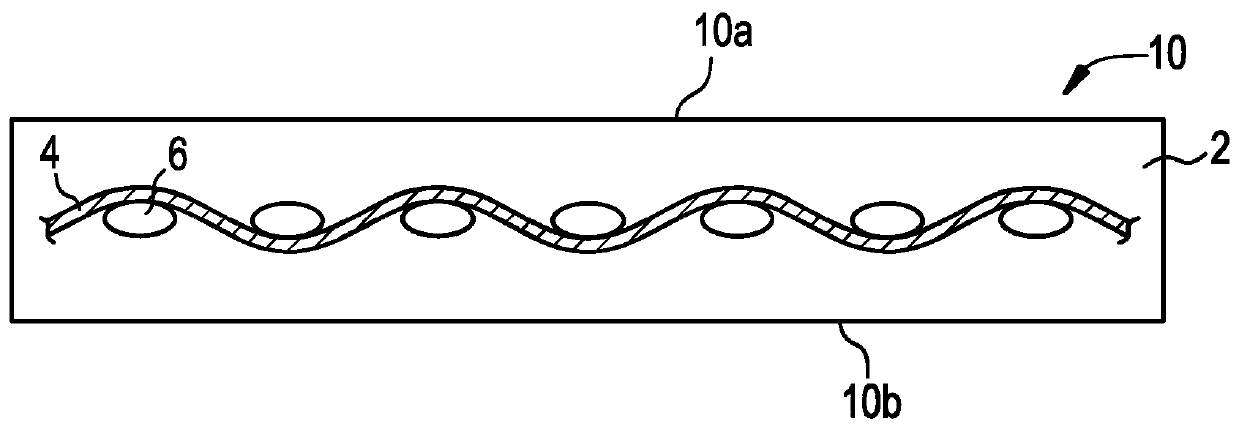

[0077] The present disclosure provides transparent composite films with ...

Embodiment 1

[0150] A resin composition consisting of 61.5% by weight (ie wt %) of M2100 [ethoxylated (10) bisphenol A Diacrylate, refractive index 1.516, Miwon Specialty Chemical Co., Ltd (Miwon Specialty Chemical Co., Ltd)]; 22wt% PE210HA (bisphenol A epoxy acrylate, refractive index 1.562, Miwon Specialty Chemical Co., Ltd); 15wt% of M1142 (o-phenylphenol ethyl acrylate, refractive index 1.577, Meiyuan Special Chemical Co., Ltd.); and 1.5wt% of Omnirad TPO-L photoinitiator [diphenyl (2,4,6-tri toluyl)phosphine oxide, BASF, Canada]. A portion of this resin composition was placed on a release film, and a glass woven fabric (1080E-glass, 40 μm thick, refractive index 1.560, purchased from Jushi Group Co., Ltd. - in Zhejiang Province, China No. 669 Wenhua South Road, Tongxiang Economic Development Zone, Zip Code 314500) was placed on the resin-coated release film, and a second portion of the resin was placed on top of the glass woven fabric. Wetting was continued for 30 minutes at about 6...

Embodiment 2

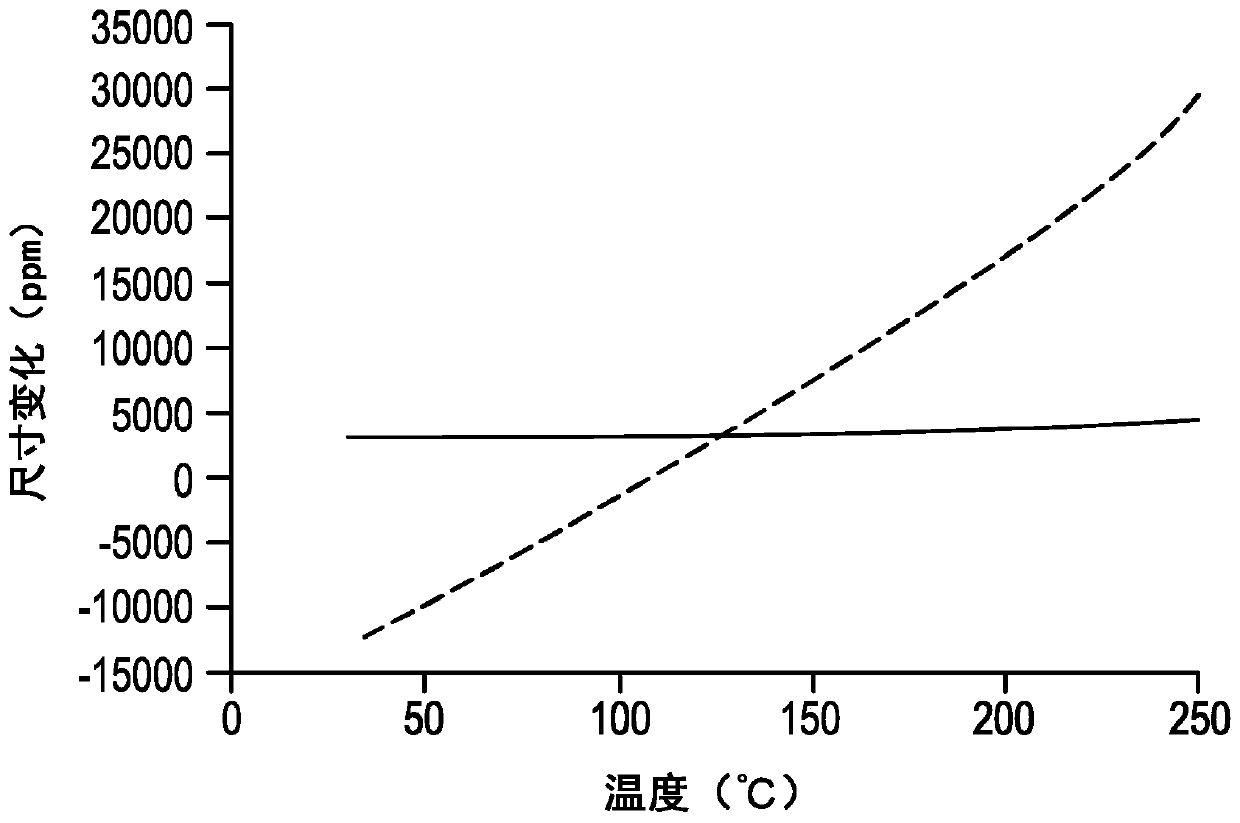

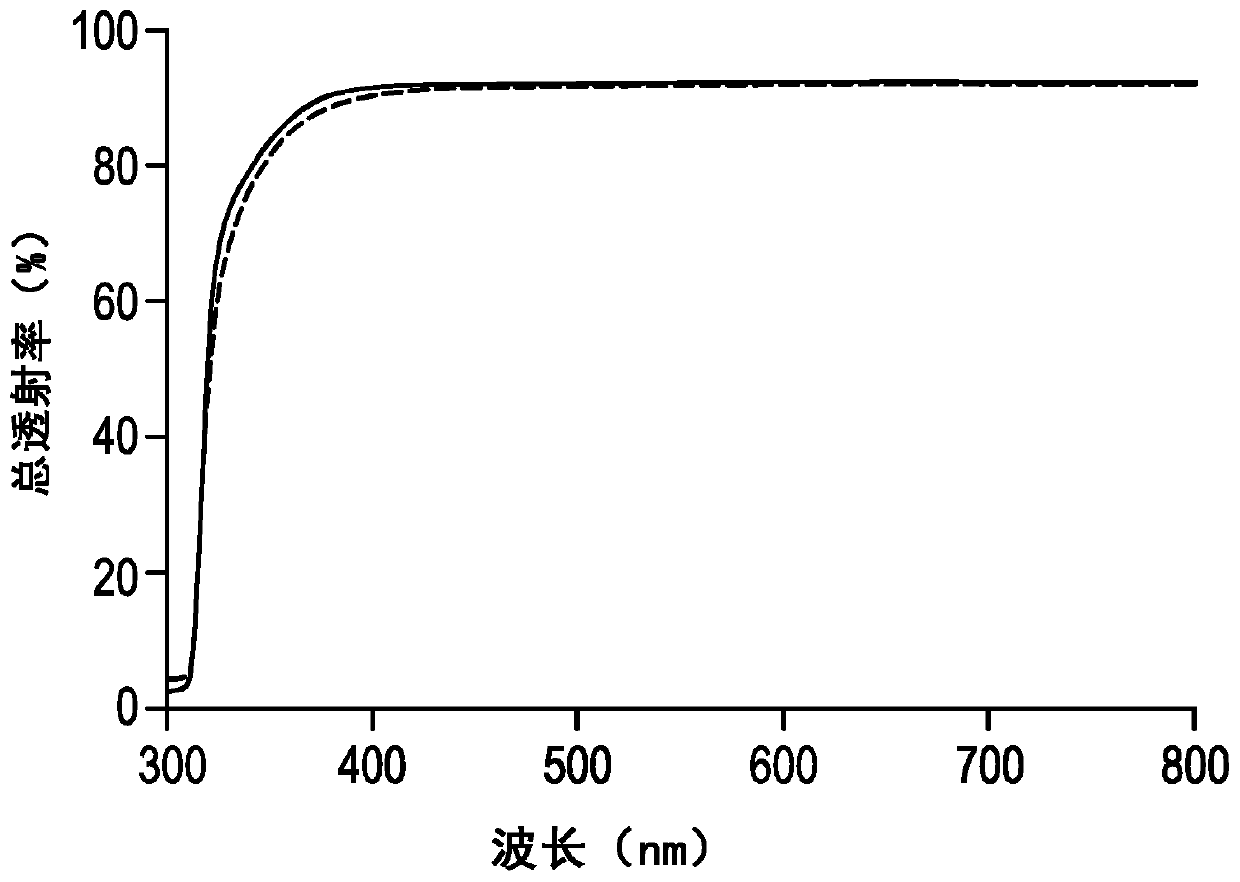

[0152] A resin composition consisting of 66.5 wt% of M2100 (ethoxylated (10) bisphenol A diacrylate, refraction 1.516, Meiyuan Special Chemical Co., Ltd.); 22wt% of PE210HA (bisphenol A epoxy acrylate, refractive index 1.562, Meiyuan Special Chemical Co., Ltd.); 10wt% of M1142 (o-phenylphenol ethyl acrylate, Refractive index 1.577, Meiyuan Chemical Co., Ltd.); and 1.5 wt% Omnirad TPO-L photoinitiator (diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide, BASF, Canada). A transparent composite film was prepared in the same manner as described in Example 1, except that the thickness of the film was 182 μm. Tables 1 and 2 show the properties of the membranes. image 3 with Figure 4 The total transmittance and glass transition temperature of the transparent composite film are shown respectively (solid line in each figure).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Average linear thermal expansion coefficient | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com