High-safety shear fork type hydraulic system of aerial work platform

A high-altitude work platform and high-safety technology, which is applied in the direction of lifting equipment safety device, fluid pressure actuating device, lifting device, etc. The effect of improved vehicle parking impact, stable low-speed walking, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

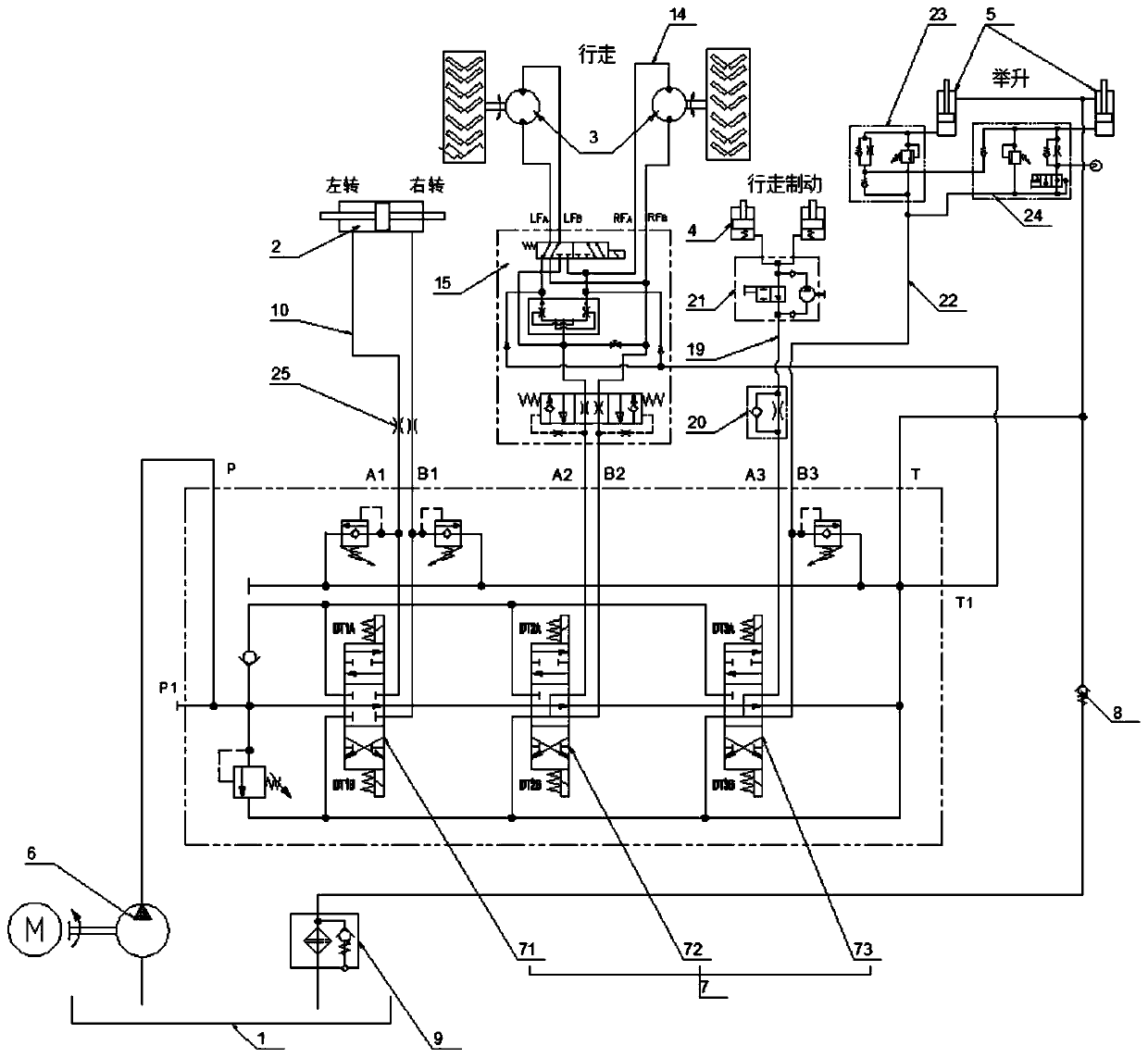

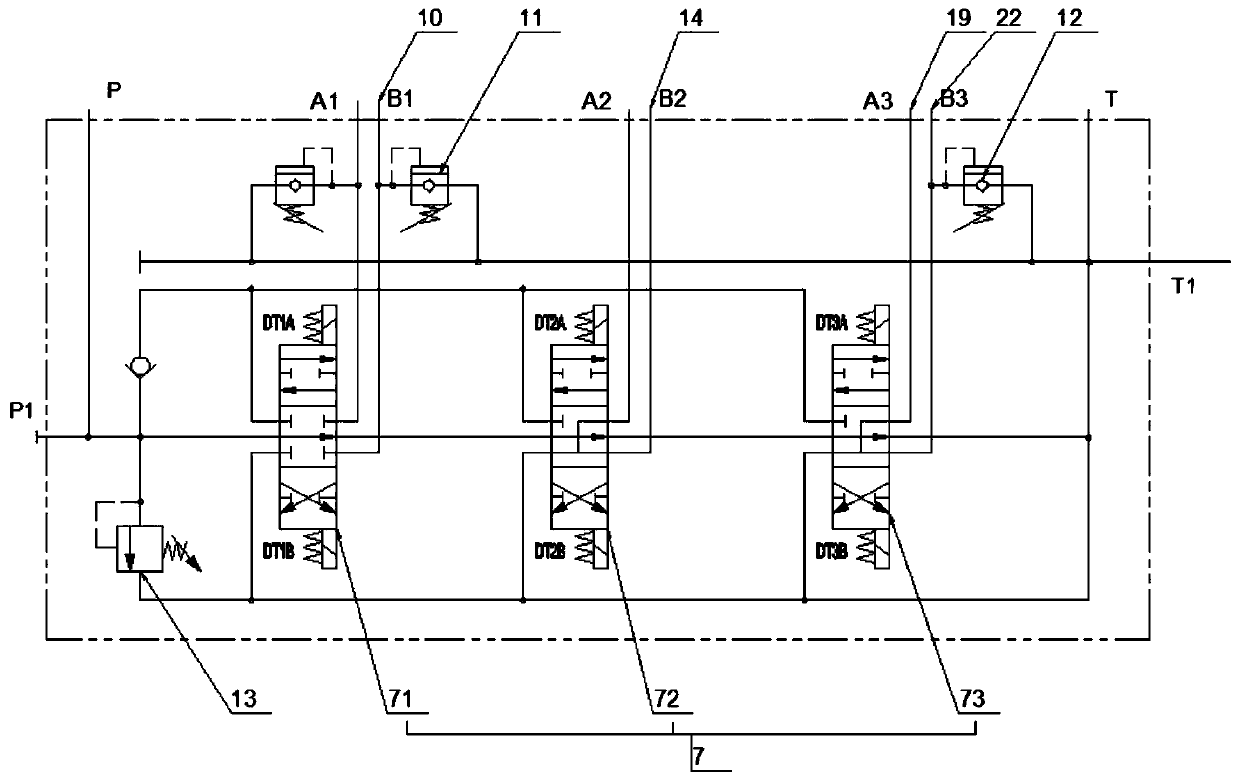

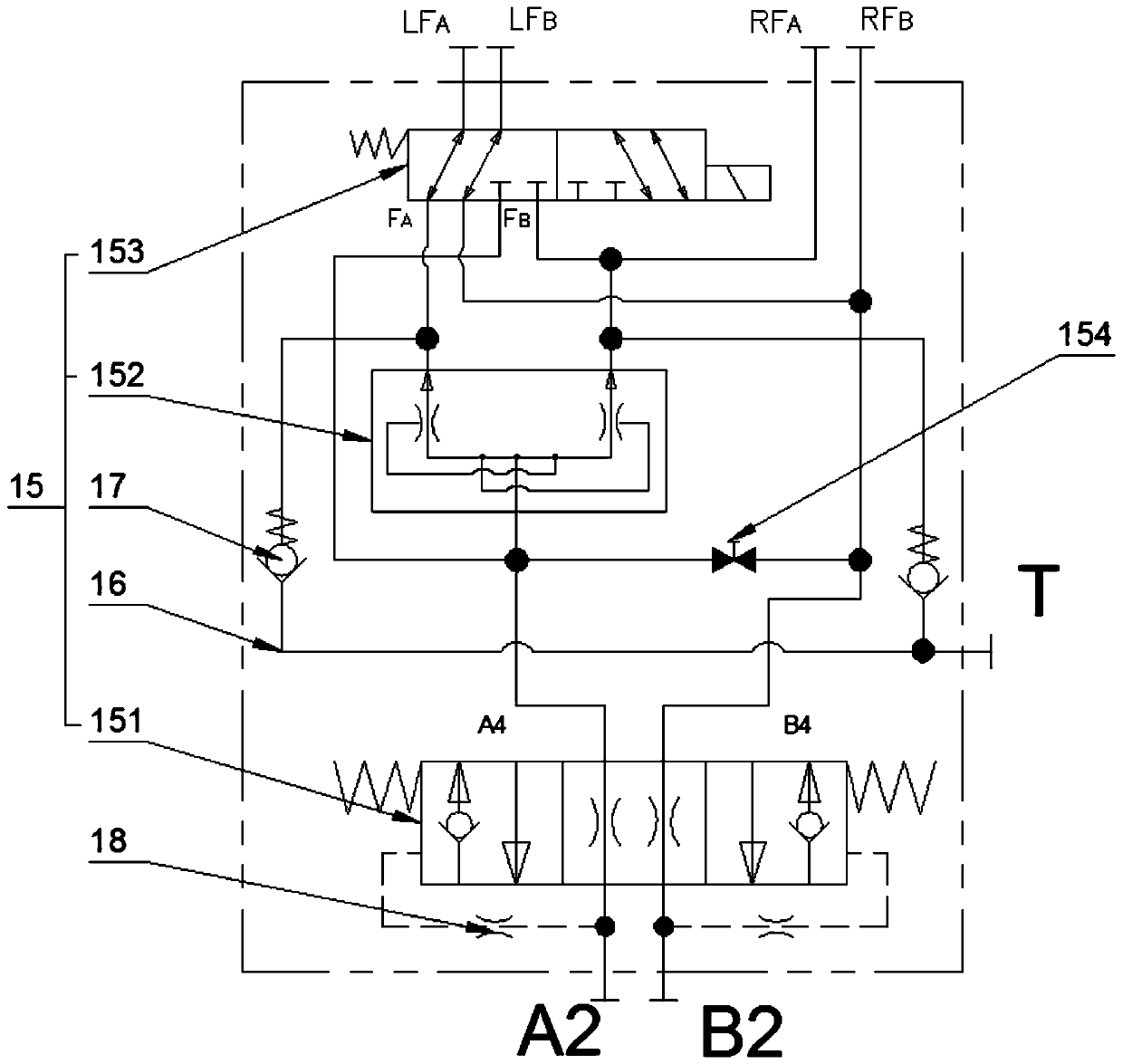

[0028] See attached figure 1 And attached figure 2 , a high-safety scissor-type aerial work platform hydraulic system, including a fuel tank 1, a steering cylinder 2, a traveling motor 3, a traveling brake 4 and a lifting cylinder 5, the fuel tank 1 is connected to a hydraulic pump 6, and the steering cylinder 2 is used to drive the steering of the work platform, the travel motor 3 is used to drive the work platform to walk, and the lifting cylinder 5 is used to drive the scissors of the work platform to lift mechanically, wherein the hydraulic pump 6 is connected with a triple electromagnetic reversing Valve 7, the triple electromagnetic reversing valve 7 has an oil inlet P and an oil return port T, and includes a connected first solenoid valve 71, a second solenoid valve 72 and a third solenoid valve 73, and the oil inlet P communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com