System and method of detecting defect in display screen by using equal-thickness interference principle

A technology of interference system and display screen, which is applied in the field of optical detection, can solve the problems of multiple detection steps, achieve high detection efficiency, prevent missed detection of defects or impurities, and achieve high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

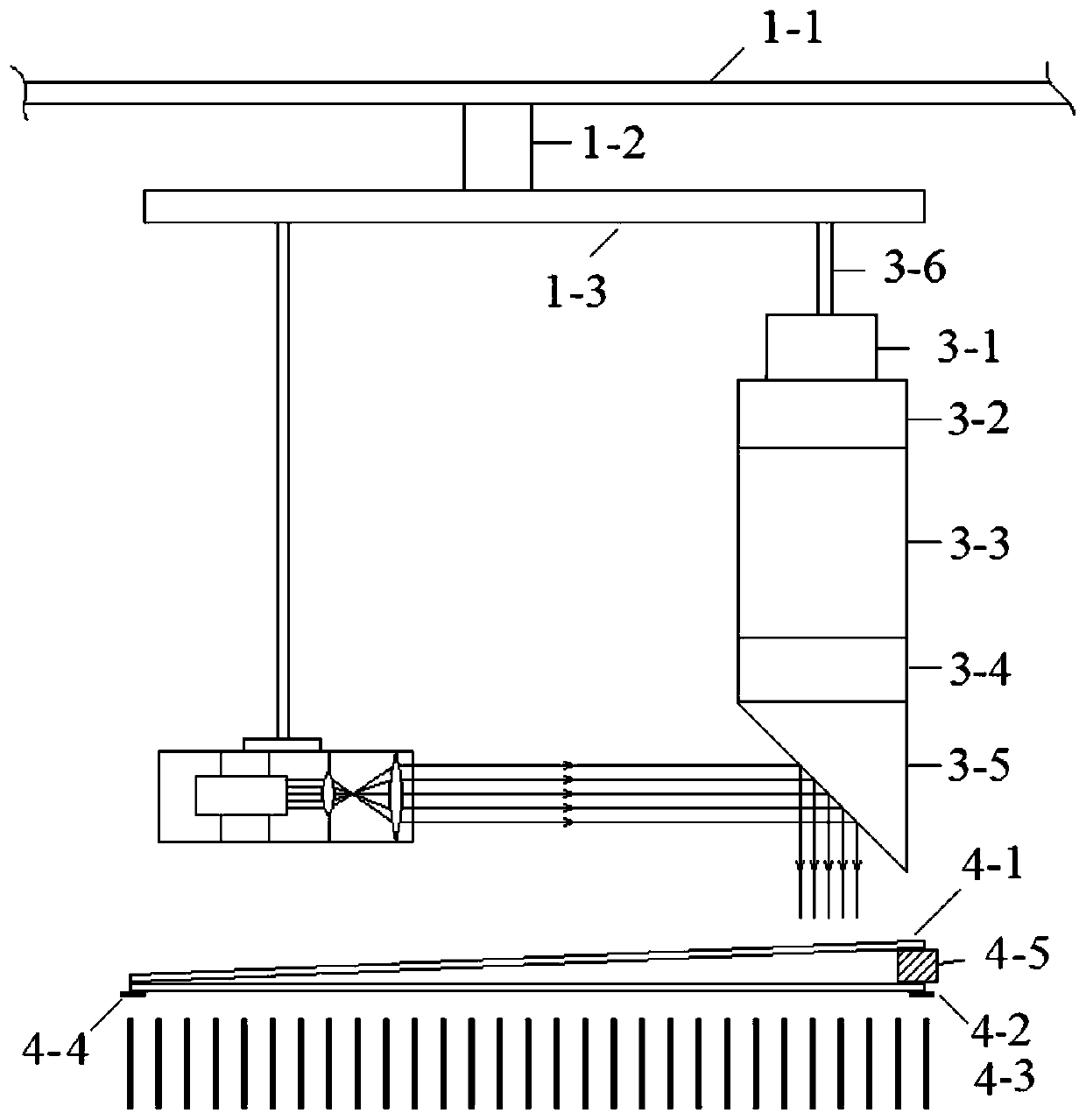

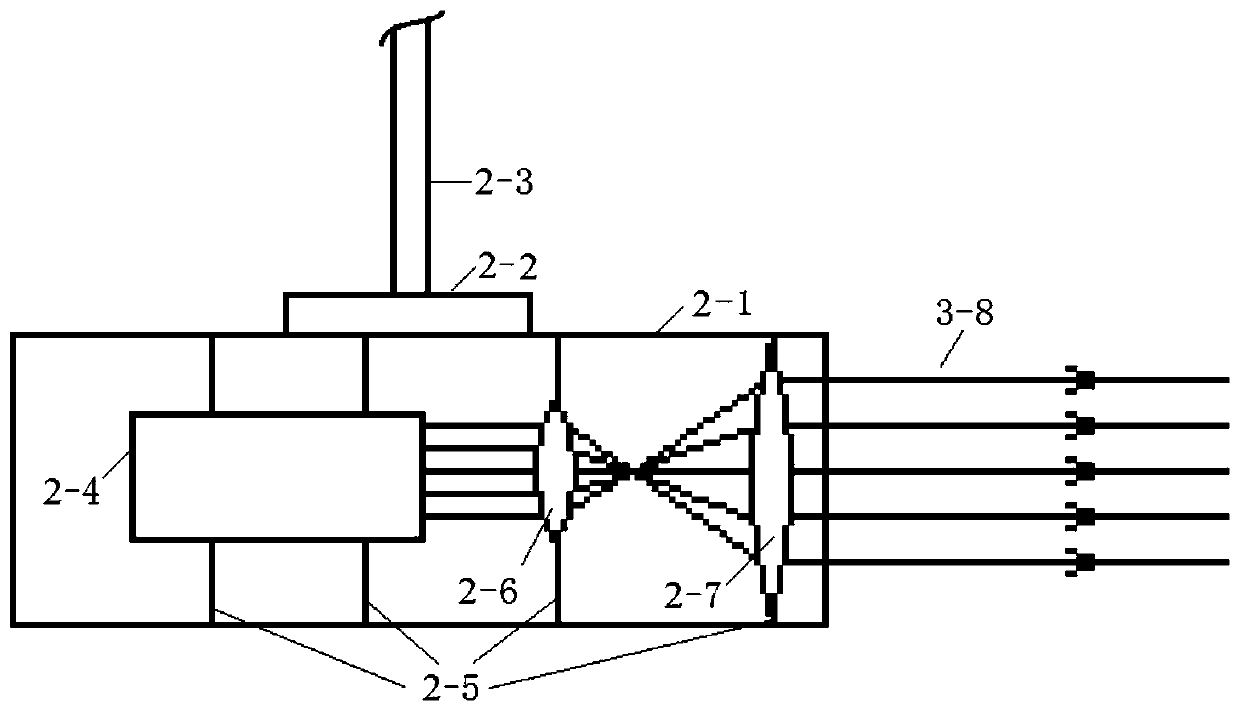

[0036] combine Figure 1 to Figure 3A system for detecting defects in a display screen using the principle of equal-thickness interference in this embodiment includes a scanning system, an interference system, and an optical microscope module. The scanning system includes a scanning bracket and a light source part and an imaging part connected to the scanning bracket. The light source Part of the emitted light is used to irradiate the interference system to generate interference fringes. The interference system includes the test glass slide 4-1 and the flat slide 4-2 placed on the bottom of the test slide 4-1, the test slide 4-1 and A clamp 4-5 is set between the flat glass slides 4-2 to form an air wedge, the scanning bracket is used to adjust the outgoing light and scan the test glass slide 4-1 horizontally and vertically, and the optical microscope module is connected with the camera part to observe and Record the change of interference fringes.

[0037] Further, in this e...

Embodiment 2

[0051] A method for detecting defects in a display screen using the principle of equal-thickness interference in this embodiment, its steps are basically the same as in Embodiment 1, further, this embodiment sets the clamping block 4-5 according to the length a of the glass slide 4-1 to be tested The height h of h / a=0.005~0.015, specifically in this embodiment, the glass slide 4-1 to be tested is a square with a side length of 2m, and the height of the clip 4-5 is calculated according to the above formula to be 10mm~30mm, in this embodiment The height of the middle clamping block 4-5 is 30mm, that is, the maximum thickness of the entire air wedge is 30mm, and the laser 2-4 in this embodiment is a green laser with a wavelength of 532nm.

[0052] As the thickness of clamping block 4-5 increases, the fringe width decreases proportionally. In order to make the interference fringes formed by the interference system easy to observe and calculate, the height of clamping block 4-5 shou...

Embodiment 3

[0054] In this embodiment, a system for detecting defects in a display screen using the equal-thickness interference principle is basically the same in structure as in Embodiment 1. Further, the light source part of this embodiment is fixed by the first connecting rod 2-3 and the fixing rod 1-3. Connected, the camera part is fixedly connected with the fixed rod 1-3 through the second connecting rod 3-6. Due to the large size of the glass display screen, if an external fixed light source is used to scan and detect a square display screen with a size of about 2m, the structure of the required fixed light source is large, and it consumes energy and wastes energy. In this embodiment, the fixed rod 1-3 can move horizontally along the sliding rod 1-1 along with the telescopic rod 1-2, and the relative position of the light source part and the camera part remains unchanged, thereby realizing the synchronous movement of the light source part and the camera part. Part of it can provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com