Method and device for controlling intelligent edge pulling machine system

A control method and control device technology, applied in computer control, program control, signal transmission system, etc., can solve the problems of single use of operation station, interference, high cost, etc., reduce the amount of sent data, increase processing speed, and avoid setting wires cable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

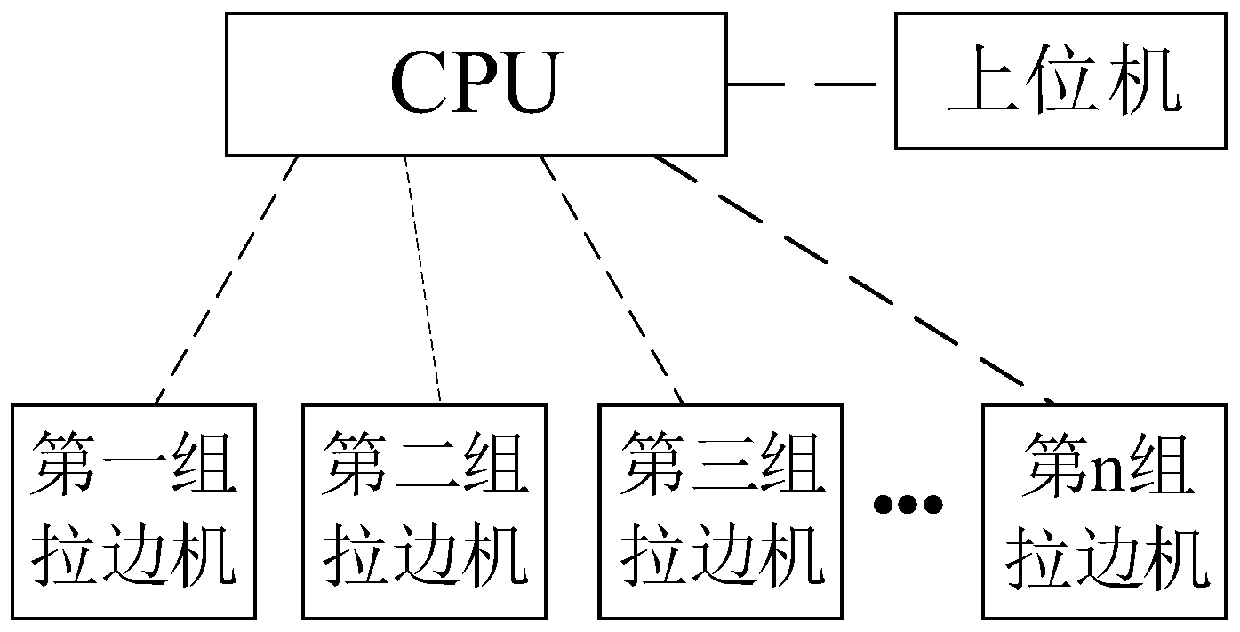

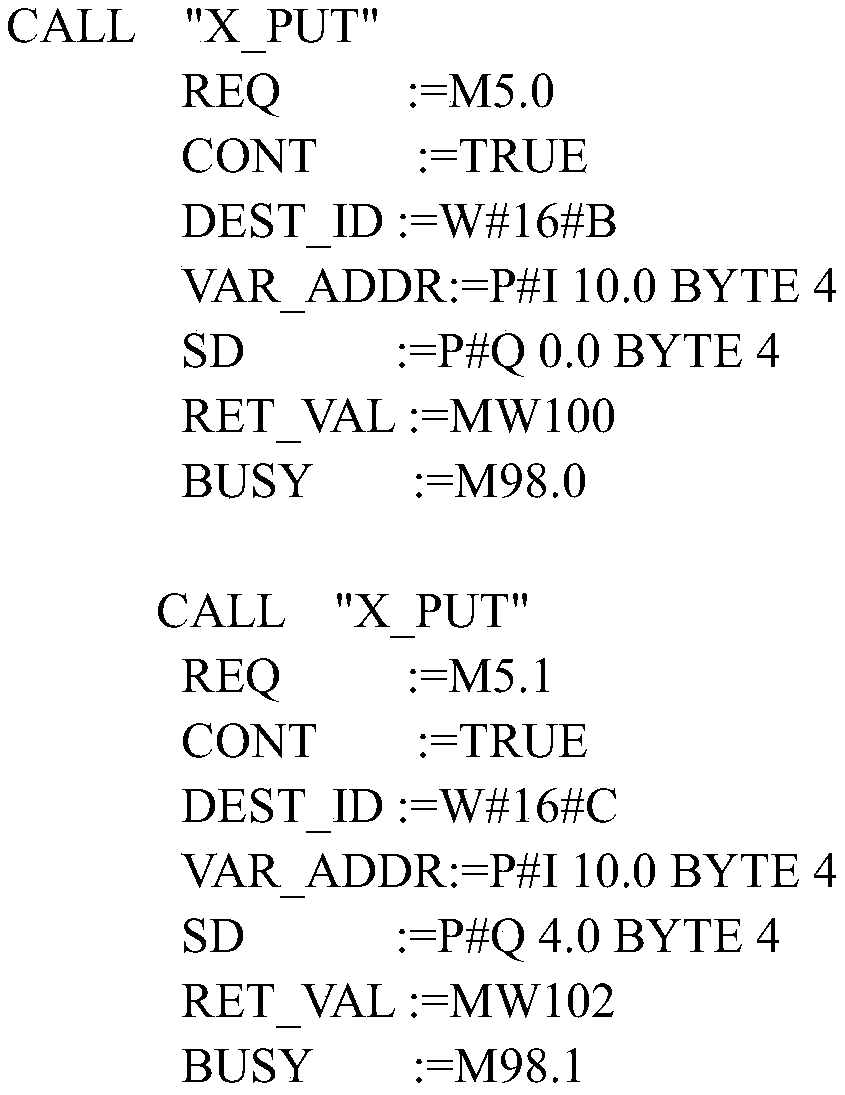

[0029] A control method for an intelligent edge-drawing machine system, the method comprising: the CPU in the main control cabinet receives data of several edge-drawing machines through wireless transmission and sends the data to the upper computer; figure 1 Shown is a schematic diagram of the connection between the CPU, the edge machine and the host computer.

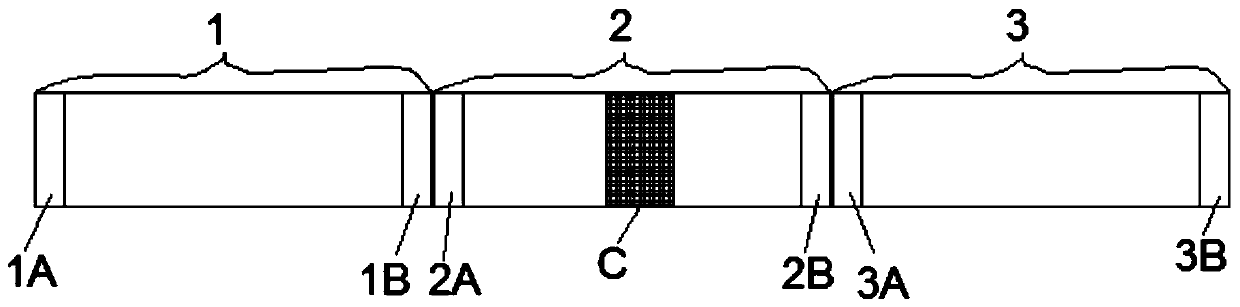

[0030] For each edge pulling machine, the edge pulling machine compares the data frame corresponding to the current cycle with the data frame corresponding to the previous cycle of the current cycle in the current cycle, and compares the data frame of the current cycle with the previous cycle The data item corresponding to the same position in the data frame of the period is replaced with a preset mark; and then the data frame of the current period after the preset mark is replaced is sent to the CPU. Such as figure 2 As shown, it is a schematic diagram of sending data to the CPU by the edge pulling machine. 1, 2, an...

Embodiment 2

[0040] Corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention also provides an intelligent edge pulling machine system control device, which includes:

[0041] The data transceiver module is used for the CPU in the main control cabinet to receive the data of several edge pulling machines through wireless transmission and send the data to the host computer; the data transceiver module includes a comparison unit and a data processing unit;

[0042] The comparison unit is used to compare the data frame corresponding to the current cycle with the data frame corresponding to the previous cycle of the current cycle in the current cycle for each edge pulling machine;

[0043] The data processing unit is used to replace the data item in the data frame of the current cycle with the same data item in the corresponding position in the data frame of the previous cycle with a preset mark; and then send the data frame of the current cycle after replacin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com