Waste gas treatment device for adhesive sticker surface paper production

A waste gas treatment device and waste gas treatment technology are applied to fixed tubular conduit components, lighting and heating equipment, indirect heat exchangers, etc., which can solve problems such as inability to treat high-temperature waste gas, generate high-temperature waste gas, and affect the surrounding environment, and eliminate Acid or sulfur products, improve purification efficiency, improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

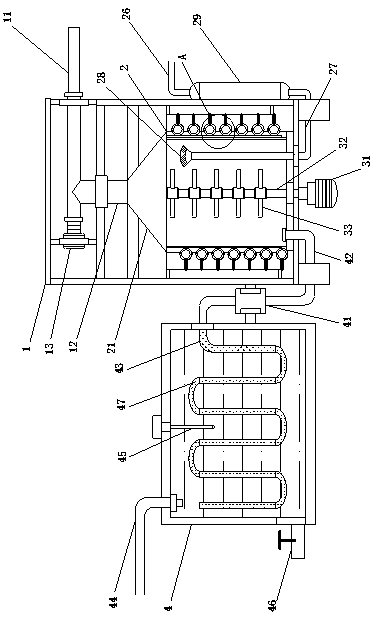

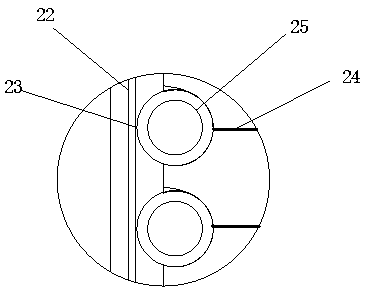

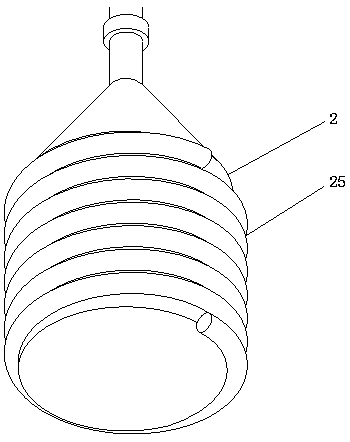

[0026] see figure 1 with figure 2 , a waste gas treatment device for the production of self-adhesive paper, the frame 1, the frame 1 is built with a waste gas treatment box 2, the waste gas treatment box 2 is a cylindrical structure, the frame The top of 1 is externally connected to the gas pipeline 11, the gas pipeline 11 is equipped with an air pump 13, and the top of the exhaust gas treatment box 2 is provided with an air intake bucket 21, and the top of the air intake bucket 21 is connected to the gas pipeline 12 by the gas pipeline 12. 13 is connected to the gas delivery end, the side wall of the exhaust gas treatment box 2 is provided with a heat exchange chamber 22, the heat exchange chamber 22 is provided with a pipe notch 23, and the bottom of the frame 1 is installed with a support A frame 24, on which a heat exchange tube 25 is installed, and the heat exchange tube 25 is fit and embedded in the pipe notch 23, and the heat exchange tube 25 has a spiral structure an...

Embodiment 2

[0033] see figure 1 , this embodiment is a further optimization of Embodiment 1. On the basis of it, the water delivery pipeline 43 is bent in an S shape and hovers in the entire inner cavity of the purification chamber 4, and the pipe wall of the water delivery pipeline 43 is provided with Several water outlet holes 47. In this application, the water delivery pipeline 43 is designed to bend in an S shape and hover in the inner cavity of the purification chamber 4. When delivering water, it is infused synchronously with the neutralizing solution conduit 44, so as to improve the mixing effect of the waste gas aqueous solution and the neutralizing solution, and improve the purification efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com